High Quality PVC Electrical Tape Made in China - Gray Packaging Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

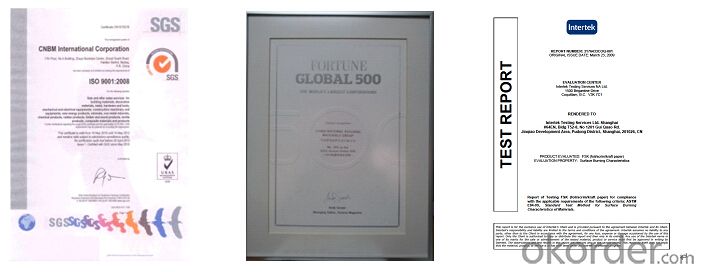

• World Top 500 Enterprises

• Resistance to cold, heat and aging

• Best quality and competitive price

• SGS&ISO9001, Customs Grade AA

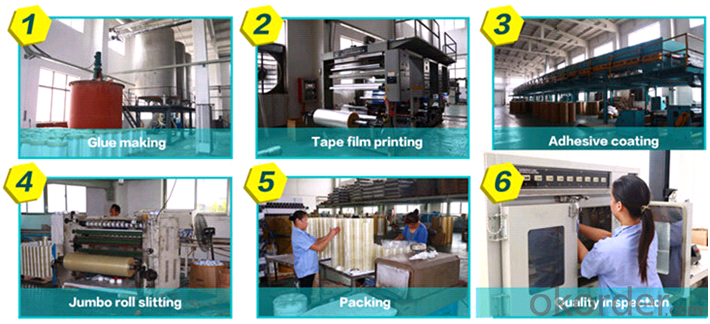

The PVC Electrical Tape is of PVC film as the carrier, coating with rubber based adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to electrical products.

The thickness of the tape can be customized.

PVC Electrical Tape is ideal for insulating, protection and color coding of electrical wires; may also be used as harness tape in automotive industry.

FEATURES:

l Excellent in adhesion and flame retardant

l Resistance to cold, heat and aging.

l High Temperature stability

l High mechanical strength and good impact resistance

l Ideal for use in dispensers

l Printable

| Standard size | 19mm*10m, 19mm*20m, 1.25m*10m, 1.25m*33m, etc |

| Thickness (micron) | 110 |

| Color | All Color Available |

| Adhesion to steel (N/cm) | 1.5 |

| Tensile Strength (N/cm) | 18 |

| Elongation at break (%) | 190 |

| Dielectric breakdown (V) | 600 |

| Flame Resistance (s) | <5 |

| Packing | Carton |

| Delivery | With 10-25days after receiving deposit |

| Payment | T/T & LC |

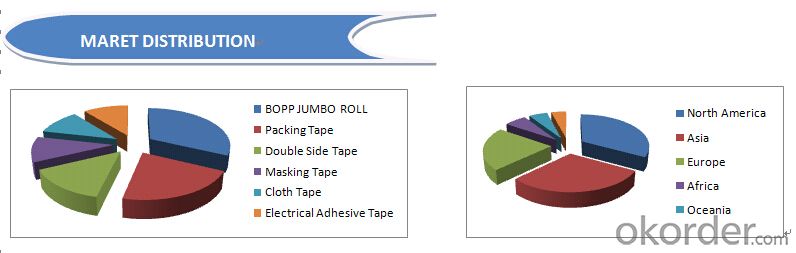

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over twenty years.

We supply various adhesive tapes: cloth tape, double sided tape, PVC tape, aluminum foil tape, Opp tape, masking tape and so on. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

We not only own professional manufacturers in China, but also work with many famous brands as agents. We can provide OEM Design & Brand as you required.

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

You are welcome to contact me at any time and visit the factory in China!

- Q: Is packaging tape transparent?

- Yes, packaging tape can be transparent. Many types of packaging tape are made from clear materials such as polypropylene or acrylic, allowing them to be see-through. This transparency is beneficial as it allows users to easily see the contents of a package without having to open it. Additionally, transparent packaging tape is often preferred in situations where a clean and professional appearance is desired, as it blends in well with various types of packaging materials. However, it is important to note that not all packaging tapes are transparent, as there are also colored or printed options available for specific purposes or branding needs.

- Q: Selection of tapes

- For colored tapes, how to distinguish between good and bad? For the colored adhesive tape, it is usually yellow and khaki. Will be sticky, pinched, and then quickly opened, you can pull one side of the adhesive off, you can see the purity and transparency of the original film. You can also look at the thickness of the glue. If no glue is pulled or pulled apart, there's a lot of impurities in it, and the glue has no cohesion. Two is too much moisture, has been volatile, at this time, the tape has already dropped a lot of adhesive force, feel can distinguish. In fact, there are many ways to distinguish between good and bad tape, as long as the life of more attention, you can distinguish between good and bad adhesive tape.

- Q: Can packaging tape be used for sealing pharmaceutical or medical supplies?

- Yes, packaging tape can be used for sealing pharmaceutical or medical supplies. However, it is important to note that not all packaging tapes are suitable for this purpose. It is recommended to use packaging tapes that are specifically designed for medical or pharmaceutical applications. These tapes are often made of materials that provide a strong and secure seal, ensuring the integrity and safety of the contents. Additionally, medical or pharmaceutical packaging tapes may also feature special attributes such as tamper-evident properties or sterilization indicators to meet the specific requirements of these industries.

- Q: How does the electrician use waterproof insulation tape?

- First, open the package and uncover and remove the insulating layer (layer of film) of the waterproof tape. Take the waterproof tape at the exposed 2CM of the conductor, lengthen 200%, and use the semi winding (half pressure half)

- Q: How do I seal a package securely with packaging tape?

- To seal a package securely with packaging tape, follow these steps: 1. Start by ensuring that the items inside the package are properly arranged and secured. 2. Cut a piece of packaging tape slightly longer than the width of the box. 3. Place the tape across the center of the box, ensuring it covers the flaps and overlaps on both sides. 4. Firmly press down on the tape to ensure it adheres properly to the surface. 5. Repeat this process with additional strips of tape, placing them parallel to the first strip and overlapping them slightly. 6. For added security, place strips of tape diagonally across the top and bottom flaps, creating an "X" pattern. 7. Apply pressure to the entire length of each strip to ensure a strong bond with the surface. 8. Finally, test the seal by gently tugging at the tape to ensure it holds firmly. By following these steps, you can seal your package securely with packaging tape, minimizing the risk of damage during transit.

- Q: Is packaging tape easy to tear?

- Indeed, packaging tape is typically quite simple to tear. Numerous packaging tapes are specifically crafted to be torn effortlessly by hand, eliminating the need for scissors or any other tools. Typically, the tape incorporates perforated lines or a slightly thinner portion that enables straightforward tearing. This feature renders it convenient for swiftly sealing or opening packages without encountering any inconvenience. Nonetheless, the ease of tearing may differ based on the particular brand and caliber of the packaging tape.

- Q: How does packaging tape differ from masking tape?

- Packaging tape and masking tape are two different types of tapes that serve different purposes and have distinct characteristics. Packaging tape is specifically designed for sealing and securing packages or boxes. It is commonly used in shipping and packaging industries. Packaging tape is typically made from a strong and durable material, such as polypropylene or PVC, which provides excellent adhesion and resistance to tearing or splitting. It is known for its high tensile strength, which ensures that the package remains sealed during transit or storage. Packaging tape also usually has a strong adhesive that sticks well to various surfaces, including cardboard, plastics, and metals. It is available in different widths and lengths to accommodate different packaging needs. On the other hand, masking tape is primarily used in painting and DIY projects. It is made from a thinner and less durable material, such as crepe paper, and has a less aggressive adhesive compared to packaging tape. The main purpose of masking tape is to create clean, straight lines and protect surfaces from paint or other liquids during painting jobs. Masking tape can be easily applied and removed without leaving residue or causing damage to the surface. It is also known for its ability to conform to uneven surfaces, allowing for precise masking and detailing work. In summary, packaging tape is designed for secure sealing and packaging of boxes and packages, while masking tape is primarily used for painting and protecting surfaces. Packaging tape is stronger, more durable, and has a stronger adhesive, while masking tape is thinner, more flexible, and can be easily removed without leaving residue.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. It provides a secure and effective way to seal the packaging, ensuring that the contents remain protected during transportation or storage.

- Q: As for the title, just bought the tape cutter, but I don't know how to use it. I bought it in plastic. Used for packing express boxes. It's better to use a process chart for me to see.. Thanks。。 Or clear words can also...

- Strip the tape first. Put your head in the cutting edge. Put the tape in the middle of the sealing machine.

- Q: What are the benefits of using easy-release packaging tape?

- The benefits of using easy-release packaging tape are numerous and can greatly simplify the packaging process. Firstly, easy-release packaging tape is designed to have a low adhesion level, which means it can be easily removed without leaving any residue or damaging the surface it was applied to. This is particularly useful when packaging delicate or valuable items, as it ensures that the tape can be removed without causing any damage. Furthermore, easy-release packaging tape is also time-saving. It can be quickly applied and removed, which increases efficiency and saves valuable time for individuals or businesses that frequently package and ship items. The ease of use also reduces the chances of mishaps or errors during the packaging process, resulting in a smoother and more streamlined experience. Additionally, the ease of release offered by this type of tape makes it more environmentally friendly. Since it can be easily removed without leaving any sticky residue, it reduces the need for excessive cleaning or scraping, which can be time-consuming and may require the use of harmful chemicals. This not only benefits the environment but also reduces costs associated with cleaning supplies and labor. Lastly, easy-release packaging tape offers versatility. It can be used for a wide range of applications, including sealing boxes, securing packages, or bundling items together. The tape is often available in different sizes and materials, allowing users to choose the most suitable option for their specific needs. Overall, the benefits of using easy-release packaging tape include easy removal without residue or damage, time-saving properties, environmental friendliness, and versatility. These advantages make it an excellent choice for anyone looking to simplify their packaging process and ensure a hassle-free experience.

Send your message to us

High Quality PVC Electrical Tape Made in China - Gray Packaging Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches