PVC Electrical Insulation Tape Factory Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

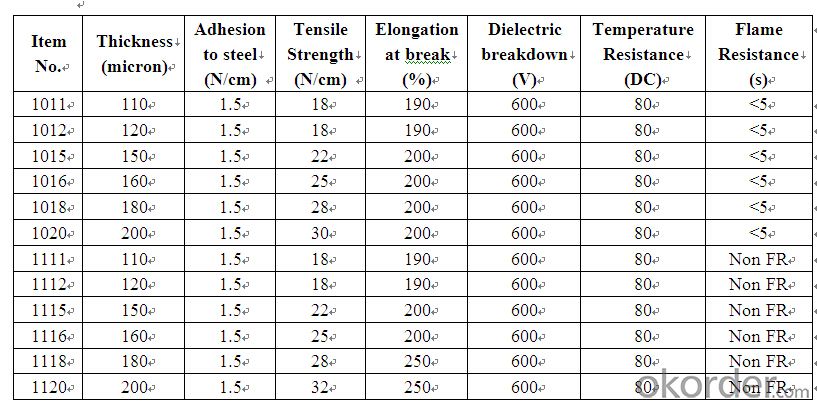

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: Can packaging tape be used for sealing musical instruments or equipment?

- Packaging tape is not recommended for sealing musical instruments or equipment. While packaging tape is designed to securely seal boxes and packages, it is not suitable for sealing musical instruments or equipment due to several reasons. Firstly, packaging tape may leave residue or adhesive marks on the surface of the instrument or equipment, potentially damaging the finish or the overall appearance. Musical instruments and equipment often have delicate finishes that require special care and attention, and using packaging tape may result in unwanted marks or damage. Secondly, packaging tape may not provide adequate protection or support for fragile or valuable musical instruments or equipment. Musical instruments, especially those made of wood, can be sensitive to changes in temperature, humidity, and pressure. Using packaging tape may not provide the necessary protection to prevent damage during transportation or storage. Instead, it is recommended to use specialized instrument or equipment cases, covers, or bags that are designed to provide proper protection and support. These cases are specifically designed to accommodate the shape, size, and fragility of musical instruments or equipment, ensuring their safety during transportation or storage. If you need to seal a case or cover for musical instruments or equipment, it is advisable to use suitable sealing methods recommended by the manufacturer. This may include zipper closures, Velcro straps, buckles, or other mechanisms designed specifically for securing musical instruments or equipment. In conclusion, while packaging tape can be useful for sealing boxes and packages, it is not suitable for sealing musical instruments or equipment. To ensure the safety and protection of your musical instruments or equipment, it is best to use specialized cases or covers designed for this purpose.

- Q: Can packaging tape be used for mailing packages?

- Yes, packaging tape can be used for mailing packages. It is commonly used to secure and seal packages, ensuring that they remain intact during transit.

- Q: Does packaging tape come in different eco-friendly options?

- Yes, packaging tape is available in different eco-friendly options. Many companies now offer packaging tape made from recycled and biodegradable materials, such as paper or plant-based adhesives. These eco-friendly alternatives help reduce the environmental impact of packaging materials.

- Q: Can packaging tape be used for mailing packages?

- Absolutely, packaging tape is perfect for mailing packages. Its main purpose is to securely seal packages and guarantee their integrity while in transit. This type of tape is known for its strength and durability, which makes it the ideal choice for securing boxes, envelopes, or any other packaging material. It is widely utilized in shipping and mailing scenarios and comes in different sizes and strengths to adapt to various package dimensions and weights. Regardless of whether you are sending a tiny envelope or a substantial box, packaging tape is an indispensable tool to guarantee the proper sealing and protection of your package throughout the mailing process.

- Q: Is packaging tape safe to use on plastic hangers?

- Yes, packaging tape is generally safe to use on plastic hangers. Packaging tape is designed to securely hold items together and can adhere well to various surfaces, including plastic. However, it's important to consider the type of plastic hanger you have and the purpose for which it is being used. While packaging tape may work well for temporarily holding clothes on a plastic hanger, it may leave residue or cause damage if left for an extended period. It's advisable to test a small area of the hanger first to ensure that the tape does not cause any harm or leave any marks. Additionally, if the plastic hanger is being used for displaying or storing delicate or valuable clothing, it may be better to opt for gentle alternatives such as fabric-friendly tape or non-adhesive hanger attachments.

- Q: Can packaging tape be used for sealing plastic food containers?

- Packaging tape is not recommended for sealing plastic food containers. While it may provide a temporary seal, it is not specifically designed for food contact and may not be safe for consumption. Additionally, packaging tape is not airtight and may not effectively keep the food fresh or prevent leakage. It is best to use food-grade sealing options such as plastic wrap, aluminum foil, or specifically designed food container lids to ensure the safety and freshness of your food.

- Q: Can packaging tape be used on different materials?

- Yes, packaging tape can be used on different materials. Packaging tape is versatile and can adhere to a wide range of surfaces, including cardboard, plastic, metal, glass, and even fabric. It is designed to provide a strong and secure seal, ensuring that packages remain intact during transportation and storage. Whether you are sealing a cardboard box, bundling items together, or securing a package, packaging tape is an effective choice for various materials.

- Q: Does packaging tape come in different colors for organization purposes?

- Yes, packaging tape does come in different colors for organization purposes.

- Q: Can packaging tape be used for packing fragile items?

- Yes, packaging tape can be used for packing fragile items. It provides a secure seal and helps to protect delicate objects during transportation or storage. However, it is recommended to use additional protective materials, such as bubble wrap or foam, to further cushion and safeguard fragile items.

- Q: Can packaging tape be used for sealing plastic toys?

- Yes, packaging tape can be used for sealing plastic toys. It provides a strong adhesive bond and helps keep the toy's packaging secure.

Send your message to us

PVC Electrical Insulation Tape Factory Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches