PVC Coated Wire Mesh -- Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of PVC Coated Wire Mesh Description

Low carbon steel wire, PVC coated wire

PVC coated after welding of steel wire. Electro galvanizing, hot-dip galvanizing or PVC coating can be done separately.

Euro fence is used as fencing, decoration or protection for various facilities in industry, agriculture, infrastructure, transport, etc.

Good corrosion resistance, good strength, anti-aging, nice appearance, easy and quick installation.

Welded ripple mesh is easy to install for fencing, decoration and security in industry, agriculture, city construction and transport.

2.Main Features of the PVC Coated Wire Mesh

• It is simple in structure

• Easy maintenance;

• Short installation period;

• Less weight;

• Easy for transport;

• Good ventilation.

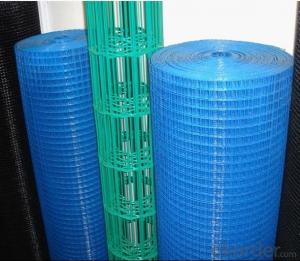

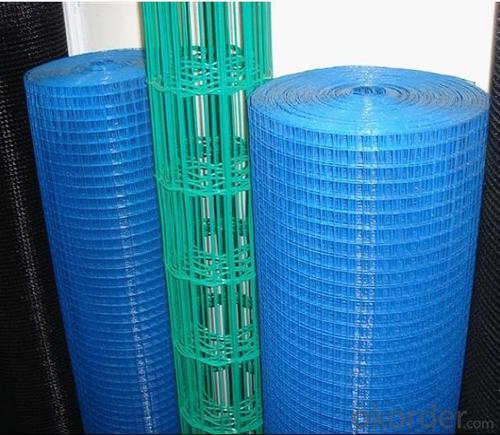

3. PVC Coated Wire Mesh Images

4. PVC Coated Wire Mesh Specification

Specification | Wire Diameter | Width |

2''×2'' | 1.0mm-1.4mm | 0.5m-2.5m |

2''×2'' | 1.2mm-1.6mm | 0.5m-2.5m |

2''×2'' | 1.4mm-1.8mm | 0.5m-2.5m |

2''×2'' | 1.6mm-2.0mm | 0.5m-2.5m |

2''×2'' | 1.8mm-2.2mm | 0.5m-2.5m |

2''×2'' | 2.0mm-2.4mm | 0.5m-2.5m |

2''×2'' | 2.5mm-3.0mm | 0.5m-2.5m |

2''×4'' | 1.4mm-1.8mm | 0.5m-2.5m |

2''×4'' | 1.6mm-2.0mm | 0.5m-2.5m |

2''×4'' | 1.8mm-2.2mm | 0.5m-2.5m |

2''×4'' | 2.0mm-2.5mm | 0.5m-2.5m |

2''×4'' | 2.5mm-3.0mm | 0.5m-2.5m |

5.FAQ of PVC Coated Wire Mesh

①The general use?

Welded Wire Mesh with excellent corrosion resistance and oxidation resistance, is extensively used as fencing, decoration and machinery protection material in agriculture, construction, transport, mine, sports field, lawn and various industrial fields

② Our Advantages?

1. Low cost for molding or tooling

2. Advanced & Standardization workshops and facilitates.

3. High-tech and high precision manufacturing equipment.

4. Strict ISO14001:2004 , ISO9001:2008 standards.

5. ROHS compliant & enviroment friendly products.

6. Professional technical specialists and management personel

7. 100% in house inspection before delivery

③Why you choose us?

We can make high precision parts from foil as thin as 0.025mm.

Main metal material we can photo etching including:

Stainless steel, iron, brass, copper, Kovar, Molybdenum

Surface can be paint color, gold/silver plated or mirror finish

Products can be made according to your drawing in .dxf or .dwg format.

Please feel free to contact us for the quotation

- Q: What is the process of the screen printing process?

- Carton printing, that is, directly in the already made a good corrugated boxes or other cartons, cartons for screen printing; ③ secondary processing, that is, first in the cardboard on the screen printing, and then according to the need to produce corrugated cardboard

- Q: How to get the correct fishing wire

- stroked the net, in the clean concrete on the grass and other things slowly removed, and then re-network when the network as a stroke when the knot again, and then you can then the next network.

- Q: Screen printing, how to print circular arc surface

- To silk screen equipment shop to do a silk screen plate, screen and the same as the normal production, the screen inversion, printing side up, the best version of the screen with a hinge fixed to facilitate up and down tilt.

- Q: Screen printing and other printing methods of the difference

- Printed high weatherability, fastness. Simple operation procedure, simple tool / machine, relatively low investment, high return rate.

- Q: The difference between screen printing characteristics

- Not subject to the size and shape of the substrate restrictions can only be printed on the plane, and silk screen can not only print on the plane, but also in the special shape of the molding and convex surface printing, but also can print a variety of large

- Q: How to clean the screen plate

- The screen will often be in the printing process, there are ink, silver paste, glue and other residues will be affixed to the hole wall, and the use of silk screen stencil cleaning machine can prevent manual cleaning is insufficient, resulting in the residue in the air curing, so that

- Q: How to make screen printing layout smooth

- Photosensitive glue in the printing surface glue 2-3 times, the back of the plastic once. Complete the photosensitive / developed after drying and curing,

- Q: Screen printing and printing the difference

- Printing (Graphic Arts, also use Graphic Communications that is graphic transmission) is the text, pictures, photos, security and other originals by plate making,

- Q: What are the characteristics of screen printing?

- Screen printing generally has the following characteristics: not subject to printing the size and shape of the restrictions, the layout of the soft pressure small

- Q: What is the principle of screen printing?

- Type of printing: no printing - such as inkjet, electrostatic copying, laser. Printed - such as movable type, off, screen.

Send your message to us

PVC Coated Wire Mesh -- Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords