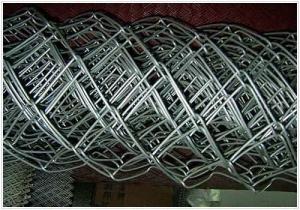

PVC Coated Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Hole Shape: | |||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Item: | Material: | Assortment: | |||

| Mesh: | Wire dia: | Length: | |||

| Height: | zinc coating: | Color: | |||

Packaging & Delivery

| Packaging Detail: | woven bags in two edge of rolls |

| Delivery Detail: | 15-25days |

Specifications

Chain link fence

1.Material: low carbon steel wire,stainless steel wire, PVC coated wire.

2.Wire dia 0.2mm~5.0mm

- Q: Can steel wire mesh be used for animal enclosures?

- Steel wire mesh proves to be an ideal choice when it comes to animal enclosures. This durable and robust material effectively contains animals, ensuring a secure enclosure. Its practicality extends to various settings, including zoos, farms, and pet enclosures, where it is commonly used for fencing and enclosures. The mesh's small gaps serve the dual purpose of preventing animals from escaping while allowing for proper ventilation and visibility. Moreover, the resistant nature of steel wire mesh against chewing makes it a fitting choice for animals that tend to chew or scratch. In summary, steel wire mesh offers reliability and versatility in the creation of animal enclosures.

- Q: Can steel wire mesh be used for mesh baskets?

- Yes, steel wire mesh can be used for mesh baskets. Steel wire mesh is commonly used for a variety of applications including mesh baskets. It is strong, durable, and resistant to corrosion, making it an ideal material for creating baskets that can withstand heavy loads and harsh conditions. The open design of the mesh allows for good airflow and visibility, making it suitable for storing and organizing items. Additionally, steel wire mesh can be easily customized to different sizes and shapes, allowing for flexibility in designing mesh baskets for specific needs.

- Q: Is steel wire mesh suitable for high-temperature applications?

- Yes, steel wire mesh is suitable for high-temperature applications. Steel has a high melting point and is known for its heat resistance, making it a reliable choice for use in high-temperature environments. Additionally, steel wire mesh provides excellent strength and durability, making it capable of withstanding the demands of such applications.

- Q: Can steel wire mesh be painted or coated?

- Yes, steel wire mesh can be painted or coated. Painting or coating steel wire mesh is a common practice to enhance its appearance, protect it from corrosion, and improve its durability. The process involves cleaning the mesh to remove any dirt, grease, or rust, and then applying a suitable primer and paint or coating. The type of paint or coating used will depend on the intended application and the environmental conditions the mesh will be exposed to. Powder coating is often preferred for its durability and resistance to chipping, peeling, and fading. Overall, painting or coating steel wire mesh can provide aesthetic benefits and increase its lifespan.

- Q: What are the different connection options for steel wire mesh panels?

- Some common connection options for steel wire mesh panels include welding, bolting, and using clips or brackets. Welding involves fusing the mesh panels together using heat, creating a strong and permanent connection. Bolting involves using nuts and bolts to secure the panels together, providing a sturdy and adjustable connection. Clips or brackets are often used to connect the panels, allowing for easy installation and removal while maintaining stability.

- Q: Can steel wire mesh be used for waste bins?

- Yes, steel wire mesh can indeed be used for waste bins. Steel wire mesh is a versatile material that offers several benefits when used for waste bins. Firstly, its sturdy construction ensures durability and longevity, making it suitable for heavy-duty use in waste management applications. Additionally, the open design of the mesh allows for proper ventilation, preventing the buildup of odors and reducing the risk of bacterial growth. The holes in the mesh also allow for easy visibility of the waste content, making it easier to identify and sort recyclable materials. Furthermore, steel wire mesh is resistant to rust and corrosion, making it suitable for both indoor and outdoor use. Overall, steel wire mesh is a practical and functional choice for waste bins, providing strength, ventilation, and visibility.

- Q: Is steel wire mesh resistant to animal bites?

- Yes, steel wire mesh is generally resistant to animal bites. The strong and durable nature of steel makes it difficult for animals to bite through or damage the mesh. However, the specific resistance may vary depending on the size and strength of the animal attempting to bite it.

- Q: Can steel wire mesh be used for reinforcement in walls?

- Indeed, walls can be reinforced using steel wire mesh. This material is frequently utilized to bolster walls, enhancing their robustness and stability. It is commonly combined with concrete, resulting in reinforced concrete walls. Throughout the construction process, the steel wire mesh is incorporated into the wall, preventing cracks and enhancing the wall's overall structural integrity. Furthermore, steel wire mesh is adaptable and suitable for various wall reinforcement purposes, including retaining walls and masonry reinforcement. All in all, steel wire mesh is a versatile and efficient material for reinforcing walls.

- Q: How is steel wire mesh typically installed?

- Steel wire mesh is typically installed by following a few common steps. Firstly, the area where the mesh is to be installed should be properly prepared. This involves cleaning the surface and making sure it is free from any debris or obstructions that could hinder the installation process. Next, the mesh should be measured and cut according to the desired dimensions. It is important to ensure that the mesh is cut accurately to fit the space it is intended for. Once the mesh is prepared, it can be attached to the desired structure or framework. This can be done using various methods, such as welding, stapling, or tying. The chosen method will depend on the specific application and the strength required for the installation. In some cases, additional support structures or frames may be needed to provide extra stability to the steel wire mesh. These supports can be installed before or during the mesh installation process, depending on the specific project requirements. Finally, after the mesh is securely attached, it is important to inspect the installation to ensure that it is properly aligned, taut, and without any visible defects. This step is crucial to ensure the longevity and effectiveness of the steel wire mesh installation. Overall, the installation of steel wire mesh requires careful preparation, accurate cutting, secure attachment, and thorough inspection to ensure a successful and durable installation.

- Q: What is the maximum temperature that steel wire mesh can withstand?

- The maximum temperature that steel wire mesh can withstand depends on various factors such as the specific type of steel used, the thickness of the wire, and the intended application. Generally, steel wire mesh can withstand temperatures ranging from 500 to 1000 degrees Celsius (932 to 1832 degrees Fahrenheit). However, it is important to consult the manufacturer's specifications or conduct specific tests to determine the exact temperature limit for a particular steel wire mesh product.

Send your message to us

PVC Coated Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords