Custom Printing Heat Resistance PVC Adhesive Tape - China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

• World Top 500 Enterprises

• Resistance to cold, heat and aging

• Best quality and competitive price

• SGS&ISO9001, Customs Grade AA

The PVC Electrical Tape is of PVC film as the carrier, coating with rubber based adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to electrical products.

The thickness of the tape can be customized.

PVC Electrical Tape is ideal for insulating, protection and color coding of electrical wires; may also be used as harness tape in automotive industry.

FEATURES:

l Excellent in adhesion and flame retardant

l Resistance to cold, heat and aging.

l High Temperature stability

l High mechanical strength and good impact resistance

l Ideal for use in dispensers

l Printable

| Standard size | 19mm*10m, 19mm*20m, 1.25m*10m, 1.25m*33m, etc |

| Thickness (micron) | 110 |

| Color | All Color Available |

| Adhesion to steel (N/cm) | 1.5 |

| Tensile Strength (N/cm) | 18 |

| Elongation at break (%) | 190 |

| Dielectric breakdown (V) | 600 |

| Flame Resistance (s) | <5 |

| Packing | Carton |

| Delivery | With 10-25days after receiving deposit |

| Payment | T/T & LC |

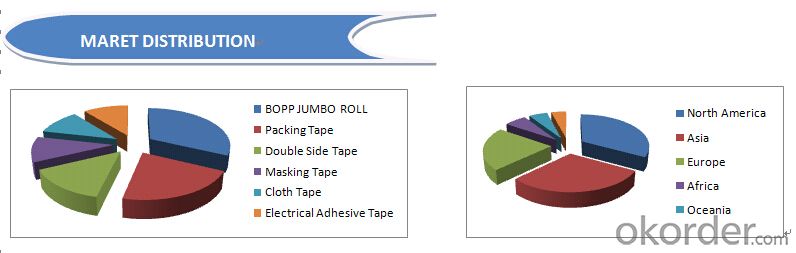

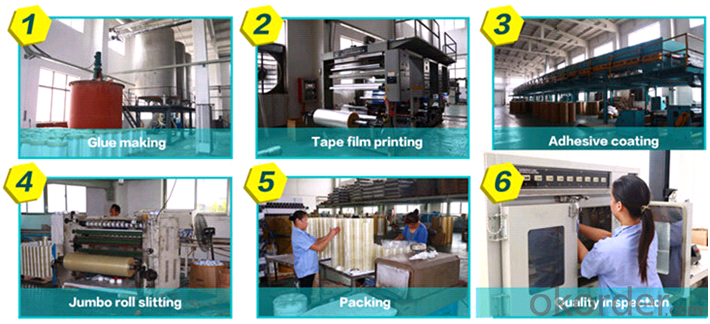

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over twenty years.

We supply various adhesive tapes: cloth tape, double sided tape, PVC tape, aluminum foil tape, Opp tape, masking tape and so on. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

We not only own professional manufacturers in China, but also work with many famous brands as agents. We can provide OEM Design & Brand as you required.

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

You are welcome to contact me at any time and visit the factory in China!

- Q: Can packaging tape be used for sealing plastic toys?

- Yes, packaging tape can be used for sealing plastic toys. It provides a strong adhesive bond and helps keep the toy's packaging secure.

- Q: How does packaging tape perform on oily or greasy surfaces?

- Packaging tape typically struggles to perform well on surfaces that are oily or greasy. The adhesive on packaging tape is specifically designed to stick to surfaces that are clean and dry. Therefore, when applied to surfaces that are oily or greasy, the tape may have difficulty sticking securely. The presence of oil or grease acts as a barrier, preventing the adhesive from effectively bonding with the surface. Consequently, there is a greater likelihood of the tape peeling or coming loose. To ensure proper adhesion on surfaces that are oily or greasy, it is advisable to clean and degrease the surface thoroughly before applying packaging tape. Using a degreasing agent or detergent can assist in eliminating the oil or grease, thereby enabling the tape to adhere more effectively. In addition, opting for a high-quality packaging tape that possesses a strong adhesive can also help overcome the challenges posed by oily or greasy surfaces.

- Q: Does packaging tape come with a dispenser?

- Packaging tape often comes accompanied by a dispenser, aiming to facilitate and optimize the application of the tape onto packages. The dispenser is usually equipped with a handle, granting you the ability to firmly grasp and manage the tape while sealing boxes or packages. This eliminates the necessity of manually cutting the tape, as well as prevents any entanglement or wastage. However, it is crucial to acknowledge that not all packaging tapes are bundled with a dispenser. Some tapes may require separate purchase, whereas others may be conveniently offered as a set, inclusive of the dispenser. It is always advisable to consult the product description or packaging for confirmation regarding the inclusion of a dispenser alongside the packaging tape.

- Q: Can packaging tape be used for sealing packages with hazardous materials?

- No, packaging tape should not be used for sealing packages with hazardous materials. Hazardous materials require specific packaging and sealing methods to ensure the safety of those handling and transporting the package. In order to meet regulatory requirements, hazardous materials should be sealed using approved methods such as special hazard tape, tamper-evident seals, or specific hazardous material labels. These methods help to clearly identify the contents of the package, prevent leakage or spillage, and provide necessary warnings and precautions for those involved in the transportation and handling of hazardous materials.

- Q: Is packaging tape resistant to oil or grease?

- Packaging tape is known for its general resistance to oil and grease. Its main purpose is to securely seal boxes and packages, offering protection to the contents during transportation. Usually, these tapes are manufactured using materials like polypropylene or PVC, which possess properties that make them resistant to different substances, including oil and grease. This resistance plays a significant role in preventing the tape from deteriorating or losing its adhesion when exposed to oils or greases commonly found in industrial or commercial environments. Nevertheless, it should be noted that the level of resistance may differ depending on the type and quality of the packaging tape employed.

- Q: Can packaging tape be used for sealing pet food or treats?

- Yes, packaging tape can be used for sealing pet food or treats. It provides a strong and secure seal to keep the contents fresh and protected. However, it is important to ensure that the tape used is safe for pets, meaning it should be non-toxic and not contain any harmful substances that could potentially be ingested by the animals. It is recommended to use pet-safe packaging tape specifically designed for sealing pet food or treats, as it meets the necessary safety requirements and regulations.

- Q: Does packaging tape come in different adhesion levels for various surfaces?

- Yes, packaging tape does come in different adhesion levels for various surfaces. There are packaging tapes available with different adhesive strengths to adhere to different surfaces such as cardboard, plastic, or metal. This allows for better packaging and ensures that the tape securely sticks to the desired surface.

- Q: What are the common price ranges for packaging tape?

- The common price ranges for packaging tape can vary depending on factors such as brand, quality, and quantity. Generally, you can find basic packaging tape in the range of $2 to $10 per roll. However, higher quality and specialty tapes may cost between $10 to $20 per roll. Bulk packs or multipacks can offer better value with prices ranging from $10 to $50 or more.

- Q: How does packaging tape perform on rough or uneven surfaces?

- Packaging tape generally performs well on rough or uneven surfaces. Its adhesive properties allow it to adhere securely to most surfaces, including those that are not perfectly smooth. The tape is designed to conform to the contours of the surface, ensuring a tight seal and preventing any potential lifting or peeling. However, it is important to note that the effectiveness of packaging tape on rough or uneven surfaces may vary depending on the specific type and quality of the tape being used. Some tapes may have stronger adhesion or more flexible backing materials, which can further enhance their performance on rough or uneven surfaces. In certain cases, it may be necessary to apply additional pressure or use multiple layers of tape to ensure a secure bond. Additionally, it is worth considering alternative packaging materials, such as stretch film or strapping, for particularly rough or irregular surfaces, as they may provide a more reliable solution.

- Q: What is the average width of packaging tape?

- The average width of packaging tape typically ranges from 1.88 inches to 2 inches. This standard width allows for efficient sealing of boxes and packages, providing a secure and reliable closure. However, it is important to note that there are variations in tape widths available in the market, with some tapes being narrower or wider to accommodate specific packaging needs or preferences.

Send your message to us

Custom Printing Heat Resistance PVC Adhesive Tape - China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords