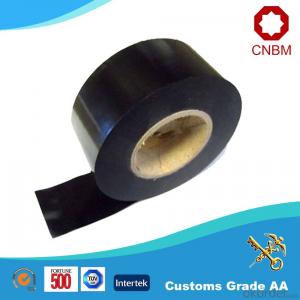

Private Label PVC Adhesive Tape for Furniture Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

| Width | 6~90mm, Customized sizes can be organized. |

| Thickness | 0.4~3mm, Customized sizes can be organized. |

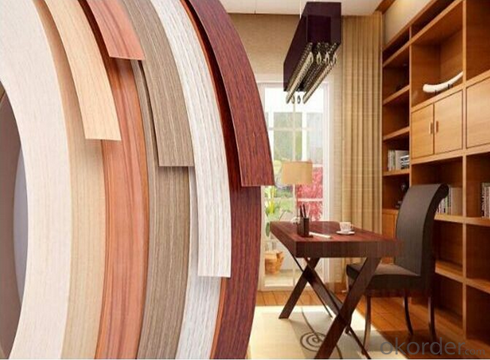

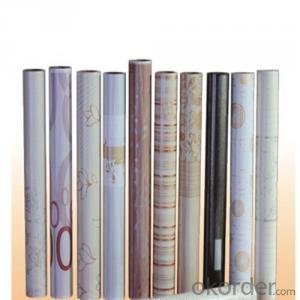

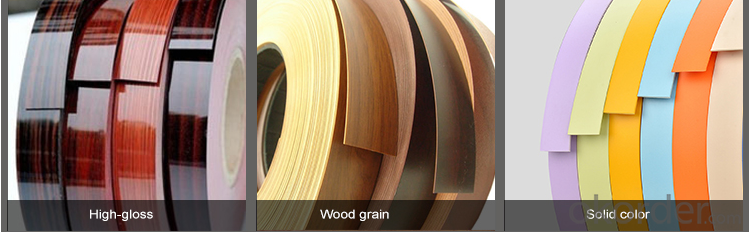

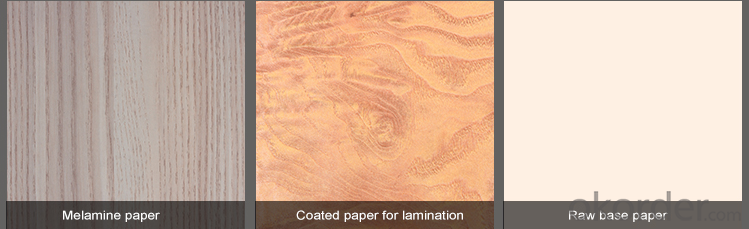

| Surface | Solid Color Collection, wood grain collection, glossy surface collection, embossing collection |

| Packing | 100m/roll, 200m/roll, rolls in carton, or according to your requirements. |

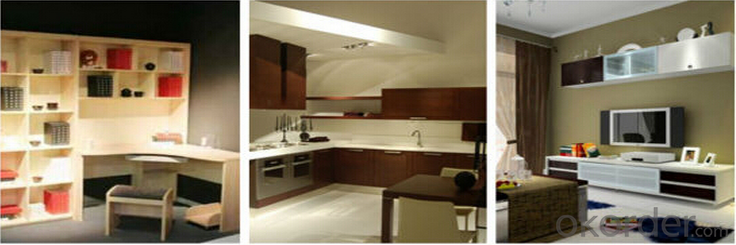

2.product show

3.Packaging & Shipping

| Payment | L/C, T/T, Western Union, MoneyGram |

| packaging | 36 Rolls/ Carton ;72 Rolls/ Carto |

| shipping | 7-21days or according to your require |

| General Shipping Methods: Ocean Freight; Air Flight |

4.Company information

CNBM International Cooperation is a subsidiary company of CNBM Group, which is one of the biggest state-owned company and Fortune 500 companies in the world.

All of our products are very affordable as a result of being produced in special economic development regions of China and we are more than happy to help you with the import/exportprocess too!

5.Our Services

(1)24 hours prompt reply by email or telephone or messenger.

(2)Standard size have stock, immediately delivery once your purchase

(3)10 days delivery containers for out of stock

(4)Can combine containers with multiple insulation products for your different demand

(5)No quantity limit, from 1 rolls to full container, at your choose and demand!

6.FAQ

1.Q:What's your payment terms?

A:L/C

2.Q:When could you send me the samples

A:2-3days

3.Q:Can I customize the strip length?

A: Yes

4.Q:Do you also sell other kinds led lights?

A:Yes, we also supply PVC tape, Warning tape, Fiberglass tape, Kraft adhesive tape, Aluminum Foil Tape, Foam double side adhesive tape etc.

- Q: Can packaging tape be used for sealing plastic containers?

- Indeed, plastic containers can be securely sealed with the utilization of packaging tape. Specially designed to adhere to diverse surfaces, packaging tape effectively prevents spillage or damage to the container's contents. While commonly employed for sealing boxes in transit or storage, it can also be employed with efficacy on plastic containers. Nevertheless, it is crucial to ensure the tape is firmly affixed and all edges and seams are adequately sealed to uphold the container's integrity.

- Q: Does packaging tape come in different dispenser options for ease of use?

- Packaging tape is available in different dispenser options, making it easier to use. The market offers various types of dispensers that are specifically designed to simplify the process of sealing boxes or packages. These dispensers come in different sizes, styles, and functionalities to accommodate different needs and preferences. One popular type of dispenser is the handheld dispenser. It is lightweight and compact, making it easy to handle and maneuver. These dispensers usually have a serrated blade for cutting the tape and a comfortable grip for better control. They are ideal for small to medium-sized packaging tasks. For larger packaging jobs, tabletop or benchtop dispensers are available. These dispensers are designed to sit on a surface and securely hold the tape roll in place, allowing for efficient and continuous taping. They often have a built-in cutting mechanism for easy and precise tape cutting. Moreover, there are automatic or electric dispensers that offer even more convenience. With these dispensers, you can effortlessly dispense and cut the tape with the push of a button, saving time and effort. They are especially useful for high-volume or repetitive packaging needs. To summarize, different dispenser options are available for packaging tape to cater to various preferences and requirements. Whether you need a handheld dispenser for small tasks or an automatic dispenser for larger volumes, there are dispenser options that can enhance the ease of use and efficiency of your packaging process.

- Q: Can packaging tape be used for sealing packages with fragile artwork or sculptures?

- Indeed, one can utilize packaging tape for the purpose of sealing packages containing delicate artwork or sculptures. Nevertheless, it is crucial to exercise caution in selecting the appropriate variant of packaging tape to guarantee the safeguarding of the artwork. In general, it is highly recommended to opt for a top-notch, robust packaging tape that has been explicitly crafted for the purpose of shipping and handling fragile or delicate items. These varieties of tape often possess added reinforcement through the inclusion of fibers or augmented adhesive strength, thereby ensuring a secure seal and averting any potential harm during transportation. Furthermore, it is advisable to employ suitable cushioning materials such as bubble wrap or foam padding to provide adequate protection for the artwork housed within the package.

- Q: Transparent sealing tape 48mm*60y what do you mean?

- 48mm is tape width. 60Y is tape length, Y means yards, yards 0.914 meters.

- Q: How does packaging tape perform on metal surfaces?

- Packaging tape performs well on metal surfaces as it adheres strongly to the smooth and flat surface, providing a secure and reliable seal. It is capable of withstanding various environmental conditions and ensures that the contents inside the packaging remain protected and intact.

- Q: Can packaging tape be used for sealing sports equipment or gear?

- Yes, packaging tape can be used for sealing sports equipment or gear. Packaging tape is designed to have strong adhesive properties, making it ideal for securing and sealing various items, including sports equipment. It can help keep equipment and gear securely fastened, preventing them from coming apart or getting damaged during transportation or storage. However, it's important to consider the specific needs and requirements of the sports equipment or gear being sealed, as some items may require more specialized tapes or sealing methods for optimal protection.

- Q: Is packaging tape resistant to chemicals?

- Packaging tape typically exhibits resistance against a broad array of chemicals. Commonly, packaging tapes are crafted from materials like polypropylene or polyvinyl chloride (PVC), renowned for their chemical-resistant properties. These materials possess the capacity to endure exposure to different chemicals, including solvents, acids, and bases. Nevertheless, it is crucial to acknowledge that the degree of chemical resistance can vary depending on the specific type and quality of the packaging tape utilized. Certain tapes may display higher chemical resistance compared to others. Furthermore, the tape's resistance can be influenced by the duration and intensity of chemical exposure. To guarantee the tape's chemical resistance, it is advisable to review the manufacturer's specifications and guidelines concerning chemical compatibility. If you are handling exceedingly harsh chemicals or engaging in specialized applications, it may be necessary to seek out packaging tapes explicitly designed for those specific conditions.

- Q: Can packaging tape be used for sealing packages with sharp or pointed objects?

- Indeed, packaging tape is capable of sealing packages that contain sharp or pointed items. Its purpose is to create a reliable seal for packages, effectively keeping together those that hold sharp or pointed objects. Nonetheless, it is crucial to ensure that the tape is tightly fastened and covers all edges and corners of the package to avoid any potential harm or damage during handling or transportation. Moreover, it is advisable to apply multiple layers of tape or employ supplementary protective measures, like cushioning materials, to reinforce the security and safeguard the sharp or pointed items enclosed within the package.

- Q: Which kind of sealing tape is solvent resistant?

- High temperature tapes are solvent resistant. Aluminum foil tape adopts high quality pressure-sensitive adhesive, good adhesion, strong adhesion, anti-aging and other effects

- Q: Can packaging tape be used for heavy-duty packaging?

- Yes, packaging tape can be used for heavy-duty packaging. There are different types of packaging tapes available in the market, including heavy-duty ones specifically designed to withstand the demands of heavy or bulky packages. These tapes are generally made with durable materials like reinforced fibers or strong adhesives that provide excellent strength and secure packaging. They are capable of holding together heavy and rigid boxes, preventing them from opening or tearing during transit. When choosing packaging tape for heavy-duty packaging, it is important to consider the weight and size of the package, as well as the specific requirements of the shipping or handling process.

Send your message to us

Private Label PVC Adhesive Tape for Furniture Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords