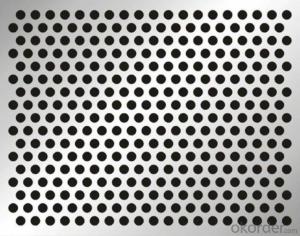

Punching Net,Rectangle Hole, Square hole, Diamond Shaped Hole

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The Description of Punching Net,Rectangle Hole, Square hole, Diamond Shaped Hole

Punching net refers to have different shaped holes in the same material, in order to adapt to different needs.

Punching net used raw materials are: stainless steel, low carbon steel plate, galvanized steel PVC cold rolled coil etc..

Feature of Punching Net,Rectangle Hole, Square hole, Diamond Shaped Hole

Can be divided into two categories: patterns of punching net, forming punching net, punching net thick, thin punching net, microporous punching net, wire cutting, punching net. Laser punching net.

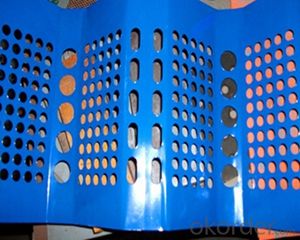

Advantage of Punching Net,Rectangle Hole, Square hole, Diamond Shaped Hole

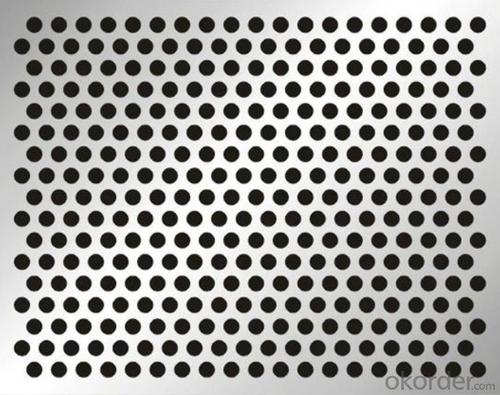

Pass: the rectangular hole, square hole, diamond shaped hole, hole, hexagonal hole, cross hole, triangle holes, Naga Madokakong, a long waist hole, plum blossom hole, scale hole, hole, star shaped hole pattern, irregular holes, drum hole etc..

Can be used for environmental noise control barriers across the city section of highway, railway, subway and other transportation facilities in the building wall, the object, the generator room, factories, and other noise sources of sound insulation and noise reduction using sound-absorbing plate, can be used for buildings, wall sound-absorbing ceiling.

Pass the specification of Punching Net,Rectangle Hole, Square hole, Diamond Shaped Hole:

The main specifications of punching net with a rectangle hole, square hole, diamond shaped hole, round hole, a slotted hole, hexagonal hole and cross hole, triangle holes, a long waist hole, plum blossom hole, pore scale, the pattern holes, eight net, herringbone hole, star shaped holes, irregular holes, the drum hole, special-shaped hole, louver etc..

1 thickness 0.2mm-1mm, length 20m

2. 1.5mm-10mm

2 1.5mm-10mm in diameter

3.0.2mm-20mm;≤1.5m*5m

3 pieces of plate thickness 0.2mm-20mm; width * length is less than or equal to 1.5m*5m

4. 0.5mm-200mm

4 0.5mm-200mm in diameter

- Q: What are the reasons for the hair making of the screen plate?

- Exposure time can refer to what you buy photoresist, generally have attached information, the above will have a reference time.

- Q: Screen printing, how to print circular arc surface

- Put down the screen began to test India, no scraper, first wrapped in white on the cup with a few copies, such as ink transfer more even when the official opening.

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- posters, business cards, binding cover, product signs and printing and dyeing textile and other silk screen pollution process first plate production The use of ink in the developer is the production of ink bucket cleaning is to produce cleaning waste or waste wipe

- Q: Screen printing has several characteristics

- What is screen printing Screen printing is a stencil printing, it is printed with flat, embossed, gravure printed together known as the four printing methods. Stamp printing, including transcript version, engraved version, spray and screen printing.

- Q: Is the screen printing the best way? And other printing methods than it?

- Irregular printing can also be used for printing, but it is best to print the area is relatively small

- Q: Screen printing ink firmness problem

- If it is PVC tablecloth, you can try to corona the first surface of the printing process, so that the surface tension higher (recommended to 55 - 60 dyne), and then see if there is improvement.

- Q: Screen printing, how to choose the screen

- You have to choose according to different moments, printing different products, imports a little better

- Q: How to make screen printing layout smooth

- You use the water-based screen version, or oily screen version. Oily general mesh is more dense. Sensitive plastic easy to have static electricity. So the glue can not play too thick. The choice of sensitive adhesive is also important,

- Q: Screen printing and printing the difference

- ink, pressure and other processes, so that ink transferred to paper, fabric, Leather and other materials on the surface, the bulk copy of the original content of the technology.

- Q: What are the characteristics of screen printing?

- Ink layer thick coverage, for all types of ink, light resistance, flexible printing and diverse

Send your message to us

Punching Net,Rectangle Hole, Square hole, Diamond Shaped Hole

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords