Prtinted Tinplate For Milk Powder, EN 10202

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

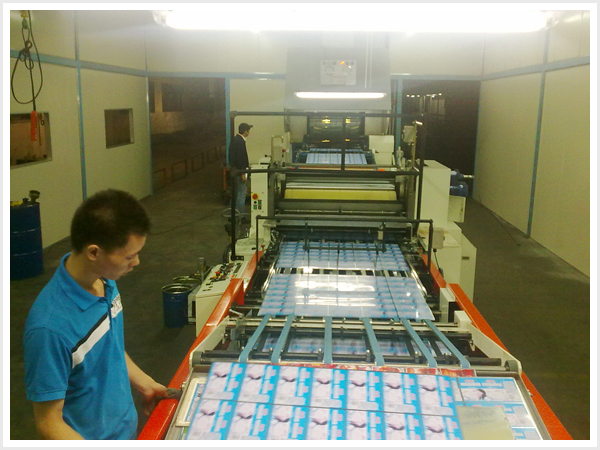

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: How does tinplate perform in terms of UV resistance?

- Tinplate generally has poor UV resistance, meaning it is not highly resistant to the damaging effects of ultraviolet radiation.

- Q: What are the chemical resistance properties of tinplate?

- Tinplate exhibits excellent chemical resistance properties, making it highly resistant to corrosion and oxidation. It can withstand exposure to various chemicals, acids, and alkalis without deteriorating or reacting with them, making it a preferred choice for packaging and coating applications in the food and beverage industry.

- Q: What industries commonly use tinplate?

- Industries commonly using tinplate include food and beverage packaging, cosmetics and personal care products, pharmaceuticals, electrical equipment, and automotive components.

- Q: Can tinplate packaging be used for sports equipment?

- Yes, tinplate packaging can be used for sports equipment. Tinplate is highly durable and can provide excellent protection for various types of sports equipment, such as balls, bats, or even smaller items like goggles or accessories. Additionally, tinplate packaging can be customized and designed in various shapes and sizes to fit the specific requirements of different sports equipment.

- Q: What are the latest innovations in tinplate technology?

- Some of the latest innovations in tinplate technology include the development of lightweight tinplate materials, improved corrosion resistance coatings, advanced printing techniques for high-quality packaging designs, and the use of recycled materials in tinplate production to promote sustainability. Additionally, there have been advancements in the manufacturing processes to enhance efficiency and minimize waste.

- Q: What are the advantages of using tinplate for electrical enclosures?

- There are several advantages of using tinplate for electrical enclosures. Firstly, tinplate offers excellent corrosion resistance, ensuring the durability and longevity of the enclosure even in harsh environments. Secondly, tinplate has high strength and rigidity, providing robust protection for the electrical components inside. Additionally, tinplate is a cost-effective option compared to other materials, making it a popular choice for mass production. Lastly, its malleability allows for complex shapes and designs, providing flexibility in enclosure manufacturing.

- Q: How does tinplate packaging contribute to product protection during shipping?

- Tinplate packaging provides excellent product protection during shipping due to its durability and strength. It acts as a sturdy barrier against external elements such as moisture, light, and air, preventing damage or contamination to the product. Additionally, tinplate packaging's ability to withstand rough handling and stacking ensures that the product remains intact and undamaged throughout the shipping process.

- Q: What are the main applications of tinplate in the medical industry?

- Tinplate is widely used in the medical industry for various applications such as packaging for pharmaceutical products, medical devices, and sterilized containers. Its corrosion-resistant properties and ability to maintain product integrity make it ideal for ensuring the safety and longevity of medical supplies. Additionally, tinplate is also employed in the manufacture of aerosol cans for pharmaceutical sprays and ointments.

- Q: How does tinplate affect the overall cost of packaging?

- Tinplate can have a significant impact on the overall cost of packaging. While tinplate is known for its durability and ability to protect products, it is often more expensive than other packaging materials such as plastic or cardboard. The cost of tinplate includes not only the material itself but also the manufacturing process, transportation, and any additional coatings or finishes. Therefore, the decision to use tinplate for packaging should be carefully considered, weighing its benefits against its higher cost.

- Q: What are the different ways tinplate packaging can be decorated?

- Tinplate packaging can be decorated in various ways including printing, embossing, debossing, hot stamping, and applying labels or decals. These methods allow for customization and branding, making the packaging visually appealing and attractive to consumers.

Send your message to us

Prtinted Tinplate For Milk Powder, EN 10202

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords