China Tinplate For Milk Powder Can-CHBA

- Loading Port:

- Tianjin

- Payment Terms:

- TT/LC

- Min Order Qty:

- 20 Tons~ 25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

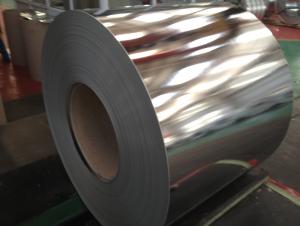

General information of Tinplate for Milk Power Can

Steel Type | MR |

Temper (BA&CA) | T1~T5, DR8 |

Coating | 2.8~8.4g/m2 |

Thickness & Tolerance | 0.15~0.5mm (Tolerance:±0.01mm) |

Width & Tolerance | 600~1000 mm(Tolerance: +2/-0mm) |

I.D | 508 MM |

Coil Weight | 3~10 MT |

Passivation | 311 |

Oiling | DOS |

Surface Finish | Bright ,Stone ,Silver ,Matte |

Min Order | 25 Tons for 1 20 feet FCL |

Package | Seaworthy Export Standard Wooden Pallet |

Standard Available | GB/T2520-2000, JIS G3303, ASTM A623, BS EN10202 |

Lead Time | 35 days after receiving buyer's original L/C or Prepayment |

Special specifications are available on customers' requirements. | |

Technical data of Tinplate for Milk Power Can

Chemical Composition(%) | Mechanical Property |

C:0.02~0.04 | Yield Strength: (Mpa):280~320 |

Si:0.01~0.03 | TensileStrength: (Mpa):340~390 |

Mn:0.18~0.22 | Elongation:20%~30% |

P:0.014~0.016 | ------------- |

S:0.006~0.009 |

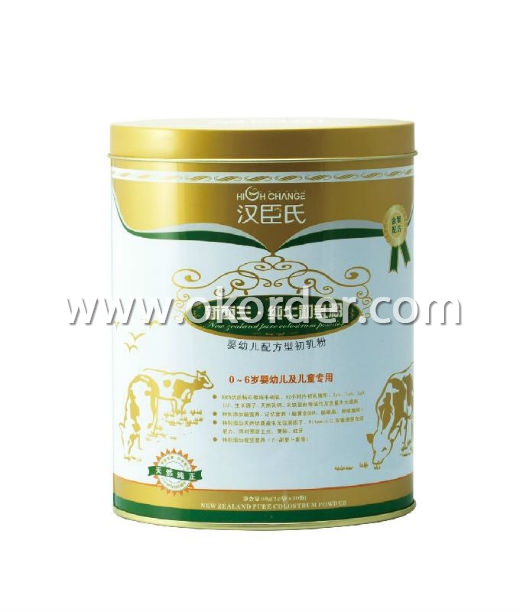

Application of Tinplate for Milk Power Can

Tinplate is widely used for making all types of containers such as artistic cans, tea cans, painting cans,

chemical package cans and metal printing etc. Its applications are not limited to containers; recently,

tinplate has also been used for making electrical machinery parts and many other products.

Equipment and Facility of Tinplate

Tin Coating Line

Cold Rolling Mill Batch Annealing Furnaces

Cutting Line Stock Area

Quantity Control System of Tinplate

- Q: How is tinplate used in the construction industry?

- Tinplate is commonly used in the construction industry for various applications. It is primarily utilized for roofing and cladding purposes due to its durability, corrosion resistance, and aesthetic appeal. Tinplate sheets are often employed in the construction of warehouses, industrial buildings, and residential structures as a protective outer layer. Additionally, tinplate can be used for decorative purposes, such as wall panels or ceiling tiles, adding a sleek and modern look to buildings.

- Q: What are the different types of tinplate finishes available?

- There are primarily three types of tinplate finishes available: bright, stone, and matte. Bright tinplate has a shiny and reflective surface, stone tinplate has a textured and grainy appearance, and matte tinplate has a smooth and non-reflective finish. These different finishes offer various aesthetic options for packaging and can be chosen based on the desired look and feel of the final product.

- Q: What are the weight advantages of using tinplate?

- One of the weight advantages of using tinplate is its lightweight nature. Tinplate is made by coating a thin layer of tin onto a steel substrate, resulting in a material that is significantly lighter than other packaging options such as glass or aluminum. This lightweight characteristic makes tinplate an ideal choice for various industries, including food and beverage, where weight reduction is essential for transportation, storage, and overall product cost efficiency.

- Q: How does tinplate impact the overall product design?

- Tinplate has a significant impact on the overall product design as it enhances the visual appeal and durability of the product. It provides a shiny and smooth surface, which can be utilized for branding and adding aesthetic elements. Additionally, tinplate offers excellent corrosion resistance, making it suitable for packaging products that require protection from moisture and oxygen. Its malleability allows for intricate shaping and forming, enabling designers to create unique and eye-catching product designs.

- Q: How is tinplate recycled?

- Tinplate is recycled through a process called steel recycling. The tin coating on the tinplate is first removed, usually through an acid bath. Then, the steel base is separated from the tin coating. The steel is melted down and used to make new steel products, while the tin coating can be reused for various applications, such as producing new tinplate or other tin-based products.

- Q: Tin can weldingHow can the side of the column of the pop top be welded or pressed?,

- Mainly divided into the tank, the tank cover and the tank bottom three parts. The tank body is made of a piece of iron material through the curl bending machine, by using copper welder and welding. Now the mainstream of aerosol cans, food cans and beverage cans are produced by this method.

- Q: Can tinplate be used for electrical applications?

- Yes, tinplate can be used for electrical applications. Tinplate, which is a thin sheet of steel coated with a layer of tin, offers good electrical conductivity and corrosion resistance. It is commonly used in the manufacturing of electrical components, such as transformers, capacitors, and circuit boards, due to its ability to provide a protective barrier against oxidation and improve solderability.

- Q: How long does tinplate packaging last?

- Tinplate packaging can last for several years, depending on the storage conditions and how well it is maintained.

- Q: What are the main advantages of using tinplate for electrical enclosures?

- The main advantages of using tinplate for electrical enclosures include its high strength and durability, excellent corrosion resistance, and good electrical conductivity. Tinplate is also lightweight and easy to form, making it a cost-effective choice for manufacturing enclosures. Additionally, tinplate is recyclable, making it an environmentally friendly option for electrical applications.

- Q: What are the main challenges in the production of tinplate?

- Some of the main challenges in the production of tinplate include sourcing high-quality tin and steel materials, ensuring proper adhesion of tin coating to the steel substrate, maintaining consistent tin coating thickness, preventing surface defects such as tin whiskers or blisters, and meeting environmental regulations related to waste disposal and emissions.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2009 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America;South America; Eastern Europe Southeast Asia; Africa; Mid East Eastern Asia; Western Europe; Central America Northern Europe; Southern Europe; Domestic Market |

| Company Certifications | HACCP;ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 270,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High;Average |

Send your message to us

China Tinplate For Milk Powder Can-CHBA

- Loading Port:

- Tianjin

- Payment Terms:

- TT/LC

- Min Order Qty:

- 20 Tons~ 25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords