High Grade Aluminum Ceramic Fiber Blanket with Glass Wool

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Family Characteristics

• Excellent handling strength

• Excellent hot strength

• Low thermal conductivity

• Low heat storage

• Light weight

• Resiliency

• Thermal shock resistance

• High heat reflectance

• Excellent corrosion resistance

• Excellent thermal stability

• Excellent sound absorption

• Excellent fire protection

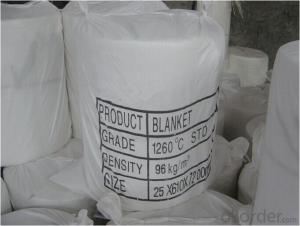

DITA Ceramic fiber blanket

is produced from high strength ceramic fibers. The blankets are air laid into a continuous mat and then are mechanically needled for added strength and surface integrity. It is double needled to provide exceptional handing strength. We can provide 5 grades of ceramic fiber blanket, including

1260C Standard,

1260C High pure,

1360C High Aluminum,

1360C Zir-alu,

1430C Zirconium.

Technical Specifications:

Item | DITA Standard | DITA High Pure | DITA High Aluminum | DITA Alu-Zirconium | DITA Zirconium | |

Classification Temp (°C) | 1260 | 1260 | 1360 | 1360 | 1430 | |

Working Temp (°C) | ≤1050 | ≤1100 | ≤1200 | ≤1200 | ≤1350 | |

Color | Pure White | Pure White | Pure White | Pure White | Pure White | |

Bulk Density (Kg/m3) | 64-160 | 64-160 | 96-160 | 96-160 | 96-160 | |

Permanent Linear Shrinkage (%) | 1000°CX24h≤3 | 1100°CX24h≤3 | 1200°CX24h≤3 | 1350°CX24h≤ 3 | ||

Thermal Conductivity (w/m.k)(128Kg/m3) | 0.09(400°C) 0.16(800°C) | 0.09(400°C) 0.16(800°C) | 0.12(600°C) 0.20(1000°C) | 0.12(600°C) 0.20(1000°C) | 0.16(800°C) 0.20(1000°C) | |

Tensile Strength (Mpa)(128Kg/m3) | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | |

Chemical Composition (%) | AL2O3 | 45-46 | 47-49 | 52-55 | 45-46 | 39-40 |

AL2O3+SIO2 | 97 | 99 | 99 | - | - | |

AL2O3+SIO2+ZrO2 | - | - | - | 99 | 99 | |

ZrO2 | - | - | - | 5-7 | 15-17 | |

Fe2O3 | ≤1.0 | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | |

Na2O+K2O | ≤0.5 | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | |

Size(mm) | Length:3600/7200 or as requested Width:610/1220 Thickness:8-60; As customers drawings. | |||||

Package | Carton with plastic bag inside, Carton size:460x460x620mm 1x20FCL load 225cartons 1x40FCL load 450cartons 1x40HC load 520cartons | |||||

Certificate | ISO9001-2000; ISO14001-2000 | |||||

Typical Applications

• Furnace, kiln, reformer and boiler linings

• Investment casting mold wrappings

• Flexible high-temperature pipe insulation

• Pressure and cryogenic vessel fire protection

• High-temperature kiln and furnace insulation

• Furnace door linings and seals

• Furnace repairs

• Thermal reactor insulation

• Primary reformer header insulation

• Glass furnace crown insulation

• Incineration equipment and stack linings

• Annealing cover seals

• Nuclear insulation applications

• Atmosphere furnace lining

• Field steam generator lining

- Q: What are the raw materials of centrifugal glass wool?

- Although I see it every day, but I really do not know about it, I only know that the main materials include glass and lime.

- Q: Does curtain wall glass wool belong to thermal insulation wool?

- , the general it is mineral wool.

- Q: Is the glass wool used in curtain wall the thermal insulation wool?

- The glass wool used for curtain wall is thermal insulation wool.However, due to the need of fireproofing, the thermal insulation material for curtain wall normally is rock wool.

- Q: Glass fiber, glass wool, what is the difference

- Glass fiber (English name: glass fiber or fiberglass) is an excellent performance of inorganic non-metallic materials, a wide range of advantages is good insulation, heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is the Crisp, poor wear resistance.

- Q: How to use glass wool for filtering?

- you can use buchner funnel or filter paper, specific question needs precious analysis, it mainly depends on the filter state, if solid particles are large, you can directly use ordinary funnel but not filter paper, when solid particles are small, you can use filter paper.

- Q: Whether the rigid section of aluminium foil glass wool can be twined with glass fiber cloth

- Yes, you can add glass silk cloth when construction and production

- Q: could experts tell me the producing method of insulating layer for glass?wool?board?

- If you have already taken the composite board as interior wall, you don't have to do the final construction, because the inside and outside layer of composite board have been very smooth and no defects, if you want to do surface construction, there will demand many materials, because there is no surface composite board, but only those with grooves on the market, and the groove itself is for increasing the weight and pressure bearing strength of composite board. Supplement: Glass wool composite board is metal surface fireproof?panel, it's mainly made of rock wool and glass wool, it takes high quality coating steel plate as the plane material, continuous cotton fiber, rock wool and glass wool as the core material, high-density hard foamed polyurethane as the tongue-and-groove filling, shaped after high pressure foaming solidified, automatic solid cotton cloth and controlled by the ultra-long precision double track.

- Q: What is the fire rating of fireproof sound-insulating glass wool board?

- Generally we do not use A1, A2 but A class, which is non-combustible levels. A level is higher than the B level. B-level is divided into B1and B2. B1 stands for flame retardant type and B2 combustible type. rock wool and glass wool both rates A class. secondly, Rockwool can endure high temperature of 800 degrees, glass wool 450 degrees.bulk density of rockwool is heavier than that of glass wool. And glass wool has better waterproof performance.

- Q: Is centrifugal glass wool board suitable for home use?

- A large number of people think that glass wool boards are harmful and that it will cause itch when contacting with the skin. And the effect is not obvious used in the surface, so it is generally used in the wall sandwich. They are harmless for wool boards have been checked, and only those which have passed the national inspection are allowed to be sold for home use. But do not use it in the surface as it is fiber products.

Send your message to us

High Grade Aluminum Ceramic Fiber Blanket with Glass Wool

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords