Prime Quality Tinplate Sheets for MR,CA,T4

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

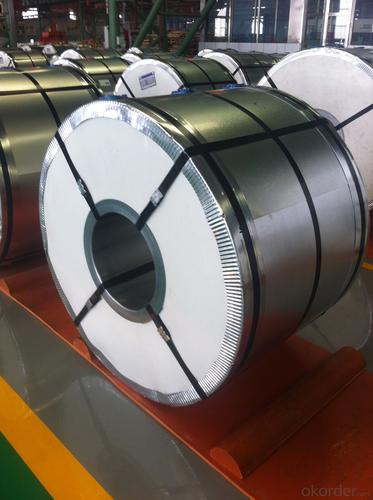

3.Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.26

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: What are the advantages of using tinplate for jewelry?

- There are several advantages of using tinplate for jewelry. Firstly, tinplate is highly durable and resistant to corrosion, making it ideal for long-lasting jewelry pieces. Secondly, tinplate is lightweight, making it comfortable to wear for extended periods. Additionally, tinplate is easy to mold and shape into various intricate designs, allowing for unique and creative jewelry pieces. Lastly, tinplate is an affordable material, making it a cost-effective option for both manufacturers and consumers.

- Q: What are the key properties of tinplate?

- Tinplate is characterized by its corrosion resistance, strong formability, and excellent storage stability, making it an ideal material for packaging applications.

- Q: What are the main applications of tinplate in the toy industry?

- Tinplate is commonly used in the toy industry for various purposes, such as manufacturing toy cars, trains, and other metal-based toys. Its main applications include providing a durable and corrosion-resistant coating, allowing for intricate and detailed designs, and creating a nostalgic and vintage feel to the toys. Additionally, tinplate is often used for packaging purposes, ensuring the safety and protection of toys during transportation and storage.

- Q: Can tinplate be used for stationery and office supplies?

- Yes, tinplate can be used for stationery and office supplies. It is a versatile material that can be easily shaped into various forms such as pencil cases, storage boxes, and document holders. Additionally, tinplate is durable, lightweight, and has a visually appealing metallic finish, making it suitable for both functional and aesthetic purposes in the stationery and office supply industry.

- Q: How does tinplate perform in terms of impact resistance?

- Tinplate generally exhibits excellent impact resistance due to its sturdy and tough nature. It can withstand moderate to heavy impacts without deforming or breaking easily, making it a reliable choice for packaging and other applications requiring durability.

- Q: How is tinplate coated with tin?

- Tinplate is typically coated with tin through a process called electroplating, where a thin layer of tin is deposited onto the surface of the tinplate using an electric current. This electroplating process helps to protect the iron or steel base of the tinplate from corrosion and also provides a smooth, shiny finish.

- Q: Can tinplate be used for HVAC systems?

- Yes, tinplate can be used for HVAC systems. Tinplate is a durable and corrosion-resistant material that is commonly used in the construction of air ducts and HVAC components. It provides excellent protection against moisture and maintains the integrity of the system, making it a suitable choice for HVAC applications.

- Q: How does tinplate contribute to the safety of automotive components?

- Tinplate contributes to the safety of automotive components in several ways. Firstly, tinplate is highly resistant to corrosion, which helps protect automotive components from rust and deterioration. This ensures that critical parts, such as brake lines or fuel tanks, remain in good condition, reducing the risk of failure and potential accidents. Additionally, tinplate's strength and durability make it suitable for impact-sensitive components, like car body panels or engine parts, providing an extra layer of protection in case of collisions. Lastly, tinplate's ability to withstand high temperatures and its fire resistance properties make it an ideal material for automotive components that may be exposed to extreme heat or fire hazards, further enhancing safety in the event of accidents or emergencies.

- Q: What are the typical lead times for tinplate production?

- The typical lead times for tinplate production can vary depending on factors such as the quantity required, complexity of the design, and the manufacturer's production capacity. However, on average, lead times for tinplate production usually range from several weeks to a few months.

- Q: What is the purpose of coating tinplate?

- The purpose of coating tinplate is to provide a protective barrier against corrosion and to enhance the appearance of the metal surface.

Send your message to us

Prime Quality Tinplate Sheets for MR,CA,T4

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords