Prime Quality Tinplate Sheets and Coils for BA,MR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

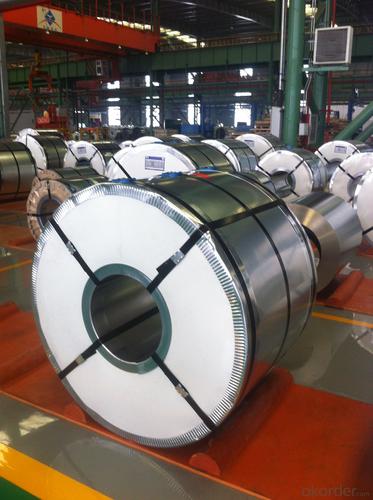

3.Images

4.Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.26

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: What's the difference between iron, aluminium, stainless steel, galvanized iron and tin?

- Iron is another kind of material. It is easy to be oxidized (embroidered) when it meets waterGalvanized sheet is made of iron, but zinc is plated on the surface to improve oxidation resistance. The price is cheap

- Q: Can tinplate be used for aerospace applications?

- Yes, tinplate can be used for certain aerospace applications, particularly for non-critical components where weight is not a significant concern. Tinplate is known for its corrosion resistance and affordability, which makes it suitable for certain aerospace applications such as interior fittings, non-structural parts, and packaging. However, for critical components that require high strength-to-weight ratio or extreme durability, other materials like aluminum or titanium are typically preferred.

- Q: What are the hygiene benefits of tinplate packaging?

- Tinplate packaging offers several hygiene benefits due to its properties. Firstly, tinplate is non-toxic and does not react with food or beverages, ensuring that the contents remain safe and unaffected. Secondly, the airtight and hermetic seal provided by tinplate packaging prevents the entry of bacteria, moisture, and other contaminants, thus preserving the quality and freshness of the product. Additionally, tinplate's resistance to corrosion and rusting minimizes the risk of contamination from external factors, enhancing the overall hygiene and safety of the packaged goods.

- Q: What are the common decorative options for tinplate packaging?

- Common decorative options for tinplate packaging include printing, embossing, debossing, hot stamping, and lithography. These techniques can be used to create intricate designs, patterns, logos, and text on the surface of the tinplate packaging, making it visually appealing and attractive to consumers.

- Q: Can tinplate packaging be used for clothing accessories?

- Yes, tinplate packaging can be used for clothing accessories. It is a durable and versatile material that can be shaped into various forms, making it suitable for packaging small items like jewelry, belts, or hair accessories. Additionally, tinplate packaging offers a unique and visually appealing option for displaying and protecting clothing accessories.

- Q: How is tinplate used in the confectionery industry?

- Tinplate is commonly used in the confectionery industry for packaging purposes. It is utilized to create tin cans and containers that are resistant to corrosion, ensuring the longevity and freshness of confectionery products. Tinplate packaging also provides a protective barrier against light, oxygen, and moisture, thereby preserving the flavor, texture, and quality of the confectionery items. Additionally, tinplate containers can be easily customized with attractive designs and labels, enhancing the visual appeal and marketability of the confectionery products.

- Q: How does tinplate contribute to the preservation of tobacco products?

- Tinplate contributes to the preservation of tobacco products by providing a durable and protective packaging material. It helps to prevent exposure to moisture, light, and oxygen, which can degrade the quality and flavor of tobacco. Additionally, tinplate cans or containers can be sealed tightly to maintain freshness and prevent the entry of external contaminants.

- Q: How does tinplate contribute to sustainable packaging?

- Tinplate contributes to sustainable packaging by being highly durable, recyclable, and resistant to corrosion. It can be reused multiple times, reducing the need for new materials. Tinplate also provides excellent protection to the packaged goods, reducing food waste and extending product shelf life. Additionally, its recyclability helps in reducing the environmental impact by minimizing waste generation and conserving resources.

- Q: How does tinplate compare to aluminum packaging?

- Tinplate and aluminum packaging have their own set of advantages and disadvantages. Tinplate is generally more affordable and has good corrosion resistance, but it is heavier and less malleable than aluminum. On the other hand, aluminum is lightweight, highly malleable, and offers excellent barrier properties, but it is more expensive and can be prone to corrosion. Ultimately, the choice between tinplate and aluminum packaging depends on specific requirements such as cost, durability, and desired aesthetics.

- Q: What are the different methods of storing tinplate packaging?

- Some of the different methods of storing tinplate packaging include stacking the tinplates on shelves or pallets, organizing them in bins or containers, using racks or hooks to hang them, or placing them in specialized storage cabinets or drawers. It is important to ensure that the storage environment is clean, dry, and free from any potential sources of damage such as moisture, extreme temperature, or direct sunlight.

Send your message to us

Prime Quality Tinplate Sheets and Coils for BA,MR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords