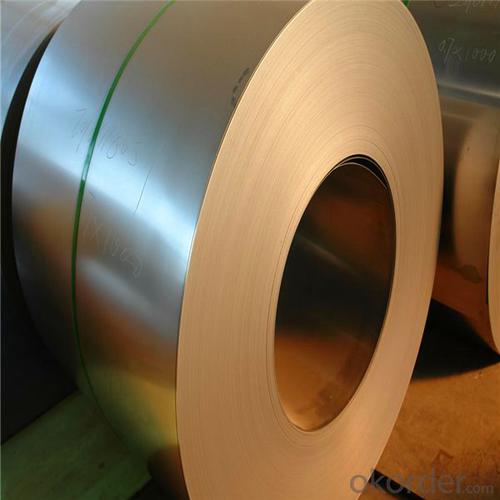

Prime Quality Cold Rolled Steel Sheet/Coil Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prime Quality SPCC Cold Rolled Steel Sheet/coil

| Usage | Widely used to appliance,automobile industry or other decoration usage. |

| Certificate | ISO9001 |

| Packing Details | Wrapped by water proof paper and plastic film.Covered with iron sheet,strapped by steel strips to protect the damage under transportation. |

| Payment term | 30%T/T in advance, the balance would be paid against the product list of manufacturer before loading,or L/C at sight |

| Delivery | 25-30 days |

| Tolerance | As the standard required |

Brief Introduction

Cold rolled steel coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold rolled steel coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The cold rolled steel coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the cold rolled steel coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final cold rolled steel coil may be manufactured in the form of sheets, strips, bars, or other forms.

- Q: What are the properties of stainless steel for medical applications?

- Stainless steel used in medical applications possesses several properties that make it ideal for such purposes. It is corrosion-resistant, which ensures that it can withstand exposure to bodily fluids and chemicals without degrading or causing contamination. Additionally, stainless steel is highly durable, making it suitable for long-lasting medical instruments and implants. It is also biocompatible, meaning it does not react with the human body, reducing the risk of adverse reactions or allergies. Furthermore, stainless steel is easy to clean and sterilize, ensuring a high level of hygiene. Overall, these properties make stainless steel a reliable and safe choice for various medical applications.

- Q: What are the different types of steel sections?

- There are various types of steel sections used in construction, including I-beams, H-beams, U-channels, angles, and flat bars. These sections have different shapes, sizes, and strengths, making them suitable for various structural applications.

- Q: How is steel used in the agricultural industry?

- Steel is used in the agricultural industry for various purposes such as constructing structures like barns and storage units, manufacturing equipment like tractors and harvesters, and creating fencing and irrigation systems. Its durability and strength make it a reliable material for supporting the needs of modern farming practices.

- Q: How do steel products compare to other materials in terms of strength and durability?

- Steel products are widely recognized for their exceptional strength and durability compared to other materials. Steel's innate strength allows it to withstand heavy loads, resist deformation, and maintain its structural integrity over time. Additionally, steel's durability enables it to endure harsh environmental conditions, resist corrosion, and have a longer lifespan compared to many other materials. Overall, steel products consistently demonstrate superior strength and durability, making them a preferred choice in numerous industries.

- Q: What are the different types of steel springs and their applications?

- There are several types of steel springs commonly used in various applications. Compression springs are used to resist compressive forces and are found in automotive suspensions, mattresses, and mechanical devices. Extension springs are designed to resist stretching forces and are commonly used in garage doors, trampolines, and industrial equipment. Torsion springs provide rotational force and are found in door hinges, clothespins, and various mechanical assemblies. Additionally, flat springs are used for applications that require flexibility, such as automotive clutches and electrical switches. These different types of springs offer varying degrees of strength, durability, and flexibility, allowing them to be utilized in a wide range of industries.

- Q: How is steel billet produced?

- Steel billet is produced through a process called continuous casting, which involves melting scrap steel in an electric arc furnace and then pouring the molten steel into a water-cooled mold. As the steel cools, it solidifies into a semi-finished rectangular shape called a billet, which can be further processed into various steel products.

- Q: How is steel used in the construction of railway bridges?

- Steel is commonly used in the construction of railway bridges due to its strength, durability, and ability to withstand heavy loads. It is used to create the main structural components of the bridge, such as beams, girders, and columns, providing the necessary support and stability for the railway tracks. Steel is also used for various other elements, including the bridge deck, railings, and connections, ensuring the overall integrity and safety of the bridge.

- Q: What are the different types of steel profiles and sections available?

- There are various types of steel profiles and sections available, including I-beams, H-beams, U-channels, C-channels, angles, and T-sections. Each type has its own unique shape and dimensions, making them suitable for different structural and construction applications.

- Q: What are the different types of steel cables and their uses?

- There are several types of steel cables, each designed for specific purposes. Some common types include galvanized steel cables, which are corrosion-resistant and often used for outdoor applications like fences and suspension bridges. Stainless steel cables are highly resistant to rust and often used in marine environments, as well as in construction and architecture. Aircraft cables, made of high-strength carbon steel, are used in aviation and heavy lifting applications. Lastly, wire ropes, composed of multiple steel wires twisted together, are utilized in various industries for lifting, towing, and rigging purposes.

- Q: How is steel used in the production of renewable energy systems?

- Steel is used in the production of renewable energy systems as it provides structural support and durability to wind turbines, solar panel frames, and hydroelectric power plants. It is also used in the manufacturing of transmission towers and electrical grids, ensuring the safe and efficient distribution of renewable energy.

Send your message to us

Prime Quality Cold Rolled Steel Sheet/Coil Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords