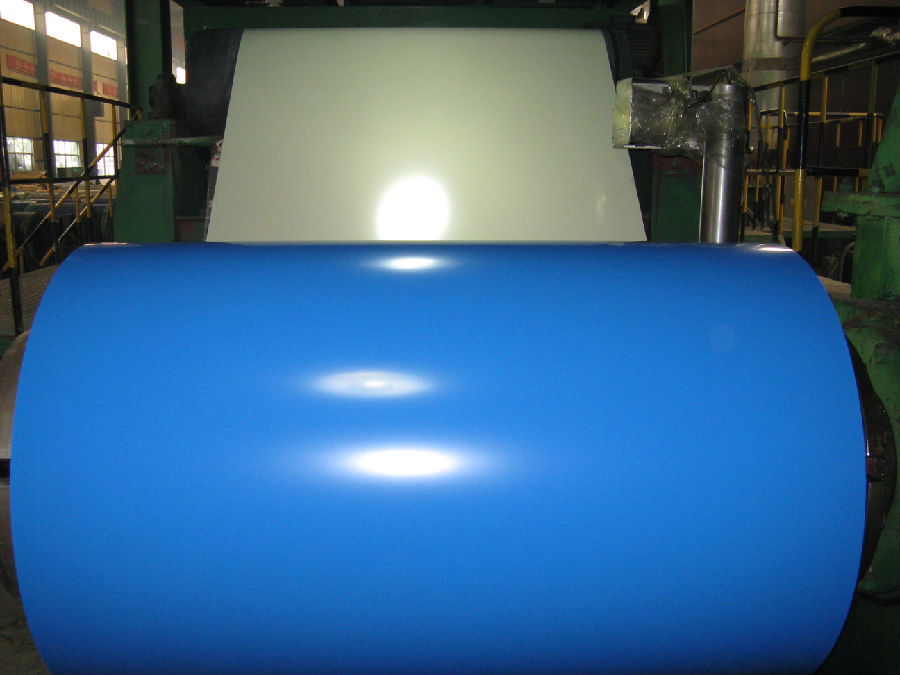

Prepainted galvanized steel coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 25000 MT m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Prepainted Galvanized Steel Coil

If you need GI and PPGI , please tell me the specification , then the best price will be send to you immediately.

Alena

- Q: basically a builder told us steel is good but when we got MFI, BQ they only have acrylic

- Acrylic or fiberglass is best, the contractor probably told you steel because it may be cheaper. Acrylic can be repaired and or painted if you decide to change colors at a later date. Steel is the older cheaper technology and cast iron is way too heavy to mess with now.

- Q: So i downloaded Broken Steel DLC for Fallout 3 for the 360. My guy is on the level where you have to activate the purifier and when i beat it. It was the normal ending that brought me back to the main menu. My friend said you have to find some guy to talk to but i don't think thats it. Please Help. P.S. i never got and conformation in-game about the download but its under the download sub menu at the main menu.

- Try Redownloading BS, That should work.

- Q: Fallout 3 take it back quest?if i am in the rotunda and dont have broken steel installed yet so i cant leave if i instal it will i be able to continue the game even if im seconds away from the end without it Additional Detailsi know it continues on but im not sure if it will let me cause i got this far without it 1 objective away from finishing the quest idk if it will change that little bit so i can continue (ps3)already in the purifier place kill col. autum liek i said just gotta do the code thing to it idk if im to far for broken steel to effect this save file

- Yes. The Broken Steel add-on goes automatically where ever you are. The thing is, I would like stand around the control room for a little while until the Broken Steel add-on is completely downloaded (Basically pop A LOT of rad-x and radaway). You should see a pop-up message saying that Broken Steel is installed and the level cap is now at 30.

- Q: What is stainless steel 316, and what are its properties and uses?

- if you want to know details, try looking it up in wikipedia. It's not a reliable source for everything, but truly technical stuff is good. It lists the exact range of elements, heats, and other things, as well as uses and things it shouldn't be used for.

- Q: How are steel coils inspected for weldability using welding tests?

- Steel coils can be inspected for weldability using a variety of welding tests. One common method is the bend test, where a section of the coil is cut and bent to evaluate the quality of the weld. This test helps determine if the weld is brittle or contains any defects that could compromise its integrity. Additionally, the guided bend test is performed to assess the ability of the weld to withstand bending without cracking or breaking. Another technique used is the macro etch test, where a sample is prepared by cutting a cross-section of the coil and then etching it with a chemical solution. This test helps reveal any imperfections or inconsistencies in the weld, such as porosity, slag inclusions, or lack of fusion. Furthermore, the hardness test is conducted to measure the hardness of the weld. This is important as excessive hardness can lead to cracking or brittleness, while insufficient hardness may result in weld failure under certain conditions. Additionally, non-destructive testing methods like ultrasonic testing, magnetic particle inspection, or radiographic examination can also be employed to detect any internal defects, such as cracks or voids, in the steel coil welds without damaging the material. These welding tests are crucial in ensuring the quality and weldability of steel coils before they are used in various applications. By conducting thorough inspections, any potential issues can be identified and addressed, ensuring that the steel coils meet the required standards for weldability and structural integrity.

- Q: What are the typical dimensions of a steel coil?

- The typical dimensions of a steel coil can vary depending on its purpose and industry standards. However, common dimensions for steel coils include a width ranging from 600mm to 2000mm, a coil diameter of around 1000mm to 2000mm, and a weight capacity ranging from a few tons to several dozen tons.

- Q: I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- Kbi Shotguns

- Q: Can steel coils be coated with fire-resistant materials?

- Yes, steel coils can be coated with fire-resistant materials. This coating can provide an extra layer of protection against fire hazards, reducing the risk of ignition and spread.

- Q: Hey everyone.I have a whetstone and a honing steel. I purposely tried to make one of my knives less sharp twice to see how well the whetstone and honing steel would work.It even seemed that when I was using my whetstone it wasn't as sharp as it was when I used my honing steel, but when I also used my honing steel after having sharpened my knife on the whetstone, it was razor sharp.I was wondering, is the whetstone only supposed to be used when the knife edge isn't as flat anymore or something? Like, only when it doesn't really have an edge anymore?Please explain your answer.Thanks everyone.

- In general, whetstones will actually remove metal in order to sharpen a blade, and the angle they're used at is important too. A steel will just straighten the blade between uses, not actually remove metal. The effect is to make it sharper than it was just before, but only because it's straighter. Using a knife makes the very thin edge kind of flatten or even fold over a bit, or get wavy, etc...so the steel just straightens it back out (imagine what happens when the very thin blade gets pressed down repeatedly on a cutting board, or even cuts through foods repeatedly). (A whetstone is used only when steeling finally just isn't enough to get the blade sharp as needed.) .

- Q: What are the different types of steel coil surface finish treatments?

- There are several different types of steel coil surface finish treatments, including hot-dip galvanizing, electro-galvanizing, zinc plating, powder coating, and painting. These treatments are applied to steel coils to enhance their durability, corrosion resistance, and aesthetic appeal.

Send your message to us

Prepainted galvanized steel coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 25000 MT m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords