prefabricated metal airplane hangar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features and services

1.firm structures and cladding

Light steel structure use efficient light thin wall material (corrugated sheet or sandwich panels).

Owing light weight ,high strength and small occupied area etc features.

2.Easy and effective production

Components are all automated, continuous, high precision production, seriation, standard product

specifications, form a complete set.All factors ensure the precision of every component.

3.Effective design and installation

Offer one-stop service from developing, design, manufacturing to installation with little mistiming.

4.Easy to assemble and disassemble

Interior decoration can be done in one time and the surface of steel structure is good for corrosion

prevision then reduce decoration fee.

5.Convenient to change and build

Increase usable area of the house,enlarge distance of pillars and supply more rooms.Easy to add

layer,reconstruct and reinforce .

6.Use new material to improve house quality

Use skylight to get sunlight and have good ventilation.

7.Environental

The house can be moved for dozend of time with plug and screw and all material can

be recycled without rubbishes.

8.Durable

The steel frame are all processed with anti-corrosion coating and can be ued fo as long

as 20-50 years.

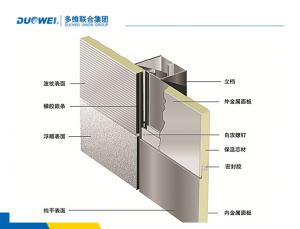

Steel Structure Components and Material

1.Main frame

Column and beam---Q235/Q345 steel with high strength and stiffness,high weight bearing

2.Secondary frame

C steel,Z steel , square tube , steel angle ,tie bar,tendsion rod and bracing.

3.Doors and windows

Sandwich panel doors,roller doors.PVC window,aluminum alloy window

4.Roof and wall materials

Semi-transparent skylight belts, Ventilators, down pipe etc .Corrugated sheets,sandwich panel(EPS,ROCK WOLL,GLASS WOOL)

5.Accessories

Semi-transparent skylight belts, Ventilators, down pipe,gutter,etc

6.Connections

Anchor,high strength/ordinary bolts,steel plate

Specifications

1.Light weight design;

2.High strength frame;

3.Easy and quick installation;

4.Recyclable component;

5.Nice appearance

Project show: light weightprefabricated steel warehouse frame

Warehouse erection in Australia --4000 sqm built in 2013

Specification -- light weightprefabricated steel warehouse frame:

Size | length X Width X Eave height, roof Slope |

Type | single slope, double slope, muti-slope; |

| single span,double-span ,multi-span; |

| single floor, double floors |

Column and beam | hot rolled or weld H section steel, grade Q345(S355JR) |

Bracing | X or V or other type bracing made from angle , round pipe |

Purlin | C or Z section size of C100~C320,Z160~Z300 |

Roof and wall | single colorful corrugated steel sheet; |

| sandwich panel with insulation of EPS, ROCK WOOL or PU |

Accessories | semi-transparent skylight belts, ventilators, down pipe, out gutter etc. |

Surface | frame steel:twice anti-corrosive primer and one finish paint; |

| secondary steel:hot galvanized |

Package and loading | nude cargo loaded into 40'HQ |

Production capacity:

main steel structure 20,000mts per annum;

secondary steel 15,000mts per annum;

various profiling steel sheet 300,000 sqm per annum.

Send your message to us

prefabricated metal airplane hangar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords