Plastic Tubes - PPR Pipes for Industrial Applications from China Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview:

1.It is used in industrial fields, agriculture and irrigation.

2.Beauty appearance.

3.Thermal insulation and energy saving.

4.Easy installation

5.excellent heat resistance and pressure resistance

6.affordable price

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Application

1) Cold and hot water systems of residence and commercial buildings

2) Transportation of industrial water supply and chemical materials

3) Pure water pipe system

4) Piping networks for rainwater utilization systems

5) Irrigation agriculture and horticulture systems

6) Transportation system of drinking water production

7) Piping networks for solar plants

8) Other pipes in industry

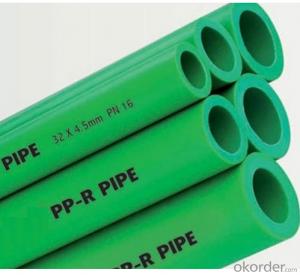

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: Are plastic tubes resistant to ultraviolet light?

- Yes, plastic tubes can be made resistant to ultraviolet light by adding UV stabilizers or using UV-resistant materials during their manufacturing process.

- Q: Can plastic tubes be used for labeling products?

- Yes, plastic tubes can be used for labeling products.

- Q: How do you seal plastic tubes?

- There are several ways to seal plastic tubes, but the most common method is to use heat. By heating the ends of the tube, the plastic melts and fuses together, creating a strong seal. This can be done using a heat gun or a specialized sealing machine. Other methods include using adhesive or solvent-based sealants, compression fittings, or even using a heat shrink sleeve to cover and seal the ends of the tube. The choice of sealing method depends on the specific requirements and materials of the plastic tubes.

- Q: Can plastic tubes be used for insulation in HVAC systems?

- Yes, plastic tubes can be used for insulation in HVAC systems. They are commonly used to insulate pipes, ducts, and other components to prevent heat loss or gain and improve energy efficiency in HVAC systems. Plastic tubes offer various benefits such as easy installation, resistance to moisture and corrosion, and cost-effectiveness.

- Q: Can plastic tubes be used for medical purposes?

- Yes, plastic tubes can be used for medical purposes. They are commonly used in clinical settings for various applications such as administering medications, draining fluids, and delivering nutrients. Plastic tubes used in medical procedures are often made from materials such as polyvinyl chloride (PVC) or silicone, which are designed to be safe and compatible with the human body.

- Q: I make models and the plastic that winds up in the trash could be reused if only I knew how to glue it. I have tried all of mine (401, epoxy, Loctite, Gorilla Glue, etc) to no avail.

- I use E-6000 clear glue for almost everything. I am a sewer and needed some weights so I used this glue on huge metal washers putting two of them together for more weight. I have had these weights for quite a few years. The trick to this glue is to let is set. According to the label is it flexible, paintable, non-flammable, waterproof, safe for photographs, etc. I would suggest not using this in an enclosed area for any length of time. Good luck - Hope that helps.

- Q: How do plastic tubes compare to rubber hoses in terms of flexibility?

- Plastic tubes generally offer more flexibility than rubber hoses.

- Q: Are plastic tubes tamper-proof?

- No, plastic tubes are not inherently tamper-proof.

- Q: Do plastic tubes have any UV resistance?

- Yes, plastic tubes can have UV resistance. Many plastic materials used to manufacture tubes, such as PVC, HDPE, and polycarbonate, can be formulated with UV stabilizers or additives that enhance their resistance to UV radiation. This resistance helps to minimize the degradation and discoloration of the plastic tubes when exposed to sunlight or other sources of UV light.

- Q: What are the physical properties of acrylic tubes (18width, 24diameter)? What is the property difference between a tube that is extruded compared to casted? All I'm really asking is which one is stronger and how strong is it? Is it easy to drill holes in them? Is PVC stronger, and what are the properties of that?

- Cast Acrylic Tubes are used in many applications in place of extruded or molded acrylic because of better machining properties, greater clarity, better resistance to heat distortion and higher tensile strength. In short: yes, cast is stronger than extruded yes, it is easy to drill holes, just take it slow It is not cut and dry which one is stronger, they are actually quite similar in certain properties such as tensile strength, flexural strength, and compressive strength. I would recommend getting a small piece of each and trying them out in your application. Just so you know, PVC is going to be cheaper than Cast acrylic at these sizes.

Send your message to us

Plastic Tubes - PPR Pipes for Industrial Applications from China Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords