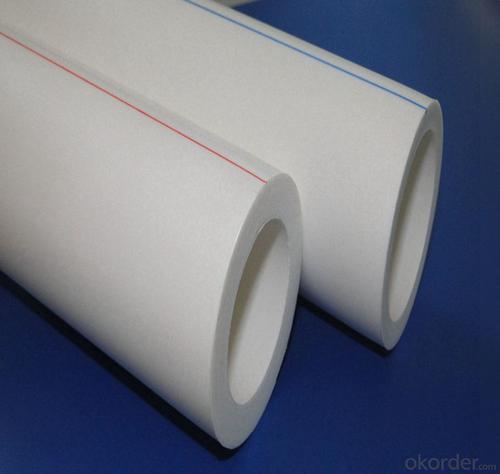

High Quality Plastic Tubes for Landscape Irrigation Drainage System PPR Pipe from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Applications of PPR Pipe

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems.

Packaging Details

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Main Product Features

Large drum hub to maximize cable life

Self-activating automatic brake hold the load securely when crank handle is released

With cable or strap

Safety guard cover available

Top quality with competitive price

Widely used in the double beam bridge crane and gantry crane

Easy to install and high quality

Packaging & Delivery

Packaging Details

package of PPR plastic pipe fitting: plastic bag or Pallets or as per customer's requirements

Delivery Time

with in 30 days days according to ordered quantity

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: i squished and kneaded the soft plastic tube but the toothpaste still came out in 3 seperate colors. i cut the tube and didnt see dividers. how does this work?

- Well it all started in China where they developed a new type of nano technology which they fused with a rare breed of elf. These micro scopic elves come from three different ethnic backgrounds. They are constantly at war and have been placed within each different colour of the toothpaste. The job of the mini elves to prevent the seperate toothpaste from mixing. When you brush your teeth it instantly kills the elves. Sadly, they are now onto us and plotting to take over the world but don`t worry. If you visit their secret cave in Hong Kong, you can join their rebellion and they will reward you will land.

- Q: Is rigid PVC double wall corrugated plastic pipe with HDEP pipe one kind?

- The HDEP drain is mainly made of HDPE resin (the formula is simple and the price will be cheaper after synthesis)

- Q: What is the minimum length of plastic tubes?

- The minimum length of plastic tubes can vary depending on the manufacturer and the purpose of the tube. However, in general, plastic tubes can be found in lengths as short as a few centimeters or even millimeters.

- Q: Can plastic tubes be used for packaging chemicals?

- Yes, plastic tubes can be used for packaging chemicals.

- Q: Are plastic tubes suitable for point-of-purchase displays?

- Yes, plastic tubes are suitable for point-of-purchase displays. They are versatile, lightweight, and can be easily customized in terms of size, shape, and color. Plastic tubes can effectively showcase products, capture attention, and enhance the overall visual appeal of the display. Additionally, they are durable, cost-effective, and can accommodate various marketing materials such as brochures, samples, or promotional items.

- Q: I would like to give all the girls in my daughter's dance company single stemmed roses after they compete in an upcoming dance competition. I tried last year just keeping the flowers in the car in water but that didn't work very well. Plus it was a hassle getting them from the car since I had my daughter's costumes, make up, etc and other props. I would like to this year use those individual water tubes that usually come on single stemmed flowers but I'm not finding them. I am buying for about 30 girls so I need to keep this as affordable as possible. Any ideas on how to create a homemade version or buy them for cheap? I will call a florist but I'm anticipating them not selling to me because they would want me to buy the roses from them (I am just buying about 2 1/2 dozen and doing it myself.Thanks so much!

- You might try using plastic tubing and plugging the ends. Glass tubing is another way to go, more durable but also more expensive more work. Glass tubing can be cut to length then closed off on one end by heating in a flame until it pulls together. Large drinking straws could work as well, you could seal the bottoms with an iron by placing the straw between aluminum foil sheets.

- Q: How are plastic tubes filled with liquids or semi-liquids?

- Plastic tubes are typically filled with liquids or semi-liquids through a process called filling. This involves using specialized machinery and equipment to accurately dispense the desired substance into the tubes. The filling process may vary depending on the viscosity and specific requirements of the product being filled. It often involves using a combination of pumps, nozzles, and controlled pressure to ensure precise and consistent filling.

- Q: i was wondering where i can get the real big sewage pipe looking tubes they have at sc village to play paintball

- the tubes are like drainage tubes, found in lumber stores, and you can ask construction wokers for leftover pieces or ask fileds for old bunkers

- Q: Can plastic tubes be used for storing flammable substances?

- No, plastic tubes should not be used for storing flammable substances as they can easily melt or catch fire, posing a significant safety risk.

- Q: Should I use them or take them off. They are currently on my strings, but my two lower strings sound really bad.

- The purpose of these plastic tubes is to prevent your bridge from being damaged. As we violinist know,the violin needs constant tuning and if you are using gut strings,would react weirdly to the physical environment should it change. The plastic tubes are to prevent your bridge from being cut by the strings especially by the E string which is very thin.Normally I take off the plastic tubes on the lower 2 strings but I think its okay if you don't too. I don't think it will affect the sound though.Maybe your strings are new so they haven't really settled down yet.Different strings when placed newly create all sorts of odd sounds.I particularly hate the Dominant ones as they have that metallic edge in the sound when its just placed.

Send your message to us

High Quality Plastic Tubes for Landscape Irrigation Drainage System PPR Pipe from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords