Powder Coating Machine for protection of can welded seam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

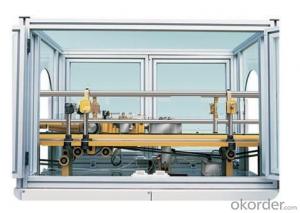

Description of Powder coating machine:

This Powder Coating Machine uses the static to spray the plastic powder onto the welding seam of can body, then use the heat to melt the powder to form a anti-corrosive film to cover the welding line to protect the welding line from being corroded. THis machine adopt the advanced PLC and pneumatic components to make the powder to be absorbed and adhered onto the welding line surface more reliably and steadily, and keep higher utilizing rate of the powder, it is the ideal equipment for can welding line coating and coverage.It can be combined with any type of welding machines to form a Fully Automatic Can Production Line.

Main Feature:

1. The Powder Coating Machine can be combined with any type of welding machines to form a Automatic Can Production Line.

2. The Powder supply can be controlled automatically, the machine will alarm and stop automatically when powder use up.

3. Powder is available to be vacuum callback and recycled.

4. The highly auti-abraded and anti-static quality material is adopted to the machine, and the static pressure can be controlled automatically.

Technical Paremeter:

| Transfer speed | 10-70m/min. |

| Production capacity | 600can/min. |

| Coating width | 8-12mm |

| Applicable can diameter | 52-280mm |

| Powder material | Polyester,Epoxies |

| Comperessed air | 0.4mpa,0.5m3/min.,relative temperature<60% |

| Input power | AC220V,50HZ, single phase |

| Power | 2.5KW |

- Q: What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q: What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q: What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resinUre-aformaldehyde resinsUrea formaldehyde polymer. Also called urea formaldehyde resin. The cross-linking English abbreviation UF. molding, the product is insoluble and infusible thermosetting resin, urea formaldehyde resin cured phenolic resin than the color of light, translucent resistance, weak acid and weak alkali, good insulation properties, excellent wear resistance, low price but, in case of strong acid and strong alkali decomposition, weather resistance is poor. The name Beetle. urea and 37% formaldehyde aqueous solution can be obtained by the polycondensation of linear urea formaldehyde oligomer in catalytic acid or alkali industry, with alkali as catalyst, reaction temperature of about 95, the molar ratio of formaldehyde to urea as 1.2.0, to ensure that the resin curing reaction. The first step to generate and dimethylol urea, then hydroxymethyl amino and soluble resin by further condensation, if by acid catalysis, easy to cause the product to be stored to gel. In neutral condition. The linear UF resin for ammonium chloride Curing agent can be cured at room temperature. The molding powder at 130 to 160 DEG C heat curing accelerators such as zinc sulfate, trimethyl phosphate, two oxalic acid ethyl ester can accelerate the curing process. The urea formaldehyde resin is mainly used in the manufacture of molded plastic manufacturing, daily life products and appliance parts, also can be used as adhesive, paper and fabric sheet the pulp, plywood, decorative board and so on. Because of its light color and easy coloring, products often colorful and magnificent.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q: What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

- Q: Energy saving reform of packaging machine

- Due to the adoption of variable frequency speed regulation, the chain drive is greatly reduced, the stability and reliability of the operation of the machine are improved, and the noise of the machine operation is reduced. It guarantees the high efficiency, low loss and automatic detection of the packaging machine. It has both a beautiful and fashionable appearance, and a healthy and smart mind.Although the transmission system used in food packaging machine is relatively simple, it has higher requirements for the dynamic performance of the transmission. The system requires fast dynamic follow-up performance and high stability speed accuracy. Therefore, we must consider the dynamic technical indicators of inverters, and select high-performance inverter to meet the requirements.

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- For custom vacuum bags, I would recommend a manufacturer who has customized experience in vacuum bags because it reduces your time cost and offers a lot of advice on packaging design and customization.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

Send your message to us

Powder Coating Machine for protection of can welded seam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords