Portland® N-TGD belt bucket elevator for tower compound fertilizer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 99 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The special elevator of tower compound fertilizer

The special elevator of tower compound fertilizer has formed a complete manufacturing standard, has established technical post for the industry .

According to professional research and development of new tape bucket product features in the chemical fertilizer industry,

The special materials characteristics of the tower granulation, such as strong corrosive, increasing additive, etc., we should improved machine improvement and process design, otherwise will lead to corrosion of steel member is faster,tape layup will be failure rapidly,the tail tension device will be failure,the incomplete discharge will cause too much of the feed back,the lock is serious,the tail will be taken ash and a series of problems, most similar equipments has these problems at present.

According to these problem, Our company’s elevator has been specific design.

1.The technical features as follows:

1.1 The steel cable belt for bucket elevator has independent intellectual property rights.

1.2 Belt joint device that has independent intellectual property rights of Bucket elevator is made special treated.

1.3 It has improved head device, matches with high wear-resisting vulcanization head wheel and cleaning device.

1.4 It has modified tail device, matches with rod cage and high precision tail wheel.

1.5 Improved strength tension mechanism of parallel four connecting rod and anti-corrosion treatment.

1.6 Shell and hopper are painted professional anti-corrosive paint.

1.7 Reduction scheme of positive pressure

1.8 The fixed technology of hopper has independent intellectual property rights.

1.9 The type of drive is suspension simply supported mechanism .

1.10 Reliable seal of head, and overall built-in tail dust bearing

1.11 The operation of control and protection device is perfect.

2 Technical Features

——Lifting height is up to 140m

——Conveying capacity is up to 1335 m3/h

——Instantaneous material temperature can reach 180°C

3 Model

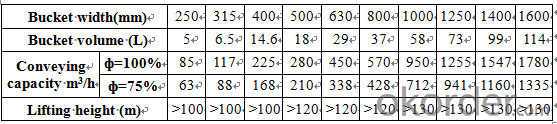

Table of conveying capacities table 1

Notes:a. The bucket volume is the volume when taking water, ф is the material filling ratio.

b. The maximum lifting height is the center distance C between the head shaft and the tail shaft.

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- The production plants of anti-wear materials are found all over the country, so that it is better to take the nearest, or increase the freight and increase the cost. It's not realistic to buy things at a low price. Where are you, the specific manufacturer can search on the Internet.

- Q: The development of material handling

- Domestic market competition is the basic material handling machinery, high-end market is mainly composed of multinational companies, domestic key large enterprise also had some markets in some specific fields; The participants in the mid-market market include large enterprises in China and small and medium-sized enterprises with excellent manufacturing technology and high management level. Many of the small scale, poor technology, poor management, lack of product innovation of enterprise, product quality is not high, low added value, poor economic benefit, in the industry of low-end market, competition is intense. "Twelfth five-year" period to 2020, is China's national economy sustainable development strategy implement and promote the development of circular economy, take a new road to industrialization, the basis for building a resource-conserving and environment-friendly society an important period. Attaches great importance to the society and the enterprise logistics role, vigorously develop modern logistics industry, to promote the development of and promote industry, improve the quality and efficiency of economic operation, enhance the comprehensive national strength and the enterprise competitiveness, has the very vital significance. It is an effective means of carrier for all walks of life of the national economy, including the manufacturing of material handling equipment which supplies the large amount of equipment needed for the second and third industries. The rapid and steady development of the national economy, the informationization and industrialization of the basic industries, provide the best opportunities for the manufacturing industry of materials handling equipment.

- Q: Why should we emphasize unitization and standardization in material handling

- Unitization is the application of scale thought to different materials. We can simplify the links, save the cost, and realize the overall optimization. To facilitate the mechanization of loading and unloading, reduce the labor intensity and improve the efficiency of the work. Reduce the damage caused by the transformation and improve the quality of logistics.

- Q: Urgent, please go to logistics expert, the question about the warehouse

- Buy a forklift truck with a solid price. You'd better consult with the company that makes the shelf and forklift

- Q: The function of material handling

- The logistics of mechanical products are very broad and the principle of improving the logistics system is: It enhances the operational training and safety of the handling personnel and increases the efficiency of labor.

- Q: The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q: What is the relevant content of the flow of materials, storage and usage

- Unitized packaging and standardization is the foundation of the enterprise logistics work, for the protection of the components, the follow-up of logistics planning and the determination of through put play a key role. Adopt the reasonable unitized equipment, can reduce the invalid labor (such as inversion, not fall to the ground) in the process of machining, improve labor efficiency, simplify the site management, reduce the security hidden danger. The idea of packaging unitization and standardization is controlled mainly from macro and micro level. On the macro level, we need to set the size chain for all materials from the perspective of the supply chain. From the tray to the turntable, the special frame should be coupled with this dimension chain. On the micro level. In order to meet the basic requirements of packaging design, such as the principle of protecting spare parts and saving space, choose the proper packaging materials, internal separation materials and so on. At the same time, the loading number of the packaging unit should be fixed so as to reduce the statistical workload of the on-site staff. Some factories have higher management requirements for packaging and line workstations, which require the packaging to be incorporated into the day-to-day management of the process. For packaging, cleaning, cleaning (cleaning oil, labeling, etc.), repair, storage, etc.

- Q: The principle of material handling

- Planning principles: plan all material handling and storage activities to achieve maximum overall operational efficiency. 2, the principle of system, to integrate various handling activities and suppliers, purchase, storage, production, testing, packaging, storage management, shipping, transportation, and the customer's operating system as a whole.

- Q: There are three things to do when the material is stacked up and down

- In a cylinder, the side wall of a cylinder is fixed a few plates of iron (the width of a cylinder is a third of the cross section of the cylinder, non-contact like a paw), rolling the bottle, leaving the inlet and outlet

- Q: What are the requirements for the science of loading and unloading

- Reduce the load ratio of the mobile carrying equipment. To optimize the utilization rate of transportation equipment and manpower. Plan all the equipment to be maintained and maintained regularly. When there are more efficient means of handling and equipment, it should replace obsolete methods and equipment.

Send your message to us

Portland® N-TGD belt bucket elevator for tower compound fertilizer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 99 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords