Popular Variety is Complete in Thick Wall Seamless Steel Pipe

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Commodity Name: Seamless steel pipe

2. Standard: API,GB,ASTM,ASME,DIN

3. Quality grade: 10#, 20#, A106B, A53B,Q235, Q345, ST37-2, ST 45, ST52.etc.

4. Dimension:

OD: 1/2"-24"

WT: 8-80mm,

length: 5.8m,6m,8m,9m,12m

5. Technique: Hot Rolled/Cold Rolled/ Cold Drawn

6.Application

Main standards of medium thickness pipe for machining are API5L,JIS G3441/3444/3445,GB8162,the pipes are applied into tubular machinery parts processing.

7. Payment Terms: L/C , T/T

8.Packing and shipment

As per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing; Hexagonal package.

For 20" container the max length is 5.8m; For 40" container the max length is 11.8m. Other options are available based on customer requests. Please discuss when placing orders.

FAQ of Seamless Pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

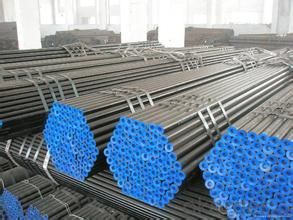

Seamless Pipe Images:

- Q: What are the environmental benefits of using steel pipes?

- There are several environmental benefits of using steel pipes: 1. Durability: Steel pipes have a long lifespan, which reduces the need for frequent replacements. This helps to conserve resources and reduces the amount of waste generated. 2. Recyclability: Steel is one of the most recycled materials in the world. When steel pipes reach the end of their life, they can be easily recycled and used to manufacture new steel products. This reduces the demand for raw materials and saves energy that would otherwise be required for the production of new materials. 3. Reduced carbon emissions: Steel pipes have a low carbon footprint compared to other materials like concrete or plastic. The manufacturing process for steel pipes produces fewer greenhouse gas emissions, contributing to a lower carbon footprint overall. 4. Resistance to corrosion: Steel pipes have high resistance to corrosion, which means they require less maintenance and repair compared to other materials. This reduces the use of chemical coatings and treatments that can have negative environmental impacts. 5. Water conservation: Steel pipes are commonly used for water supply and distribution systems. They have smooth interiors that minimize friction, reducing the amount of energy required to pump water through the pipes. This helps to conserve energy and decrease the carbon emissions associated with water transportation. 6. Fire resistance: Steel pipes are inherently fire-resistant, which makes them a safer choice for many applications. In the event of a fire, steel pipes can help to contain the spread of flames and minimize damage to the environment. Overall, the use of steel pipes offers numerous environmental benefits such as durability, recyclability, reduced carbon emissions, water conservation, and fire resistance. These factors make steel pipes a sustainable choice for various infrastructure projects.

- Q: How are steel pipes protected against electrolytic corrosion?

- Steel pipes are protected against electrolytic corrosion through a variety of methods. One common method is the application of protective coatings on the surface of the pipes. These coatings act as a barrier, preventing direct contact between the steel and the surrounding environment, which includes moisture and other corrosive substances. Coatings such as epoxy, polyethylene, and zinc are commonly used for this purpose. Another method of protection is the use of sacrificial anodes. Sacrificial anodes are made from a metal that is more reactive than steel, such as zinc or aluminum. These anodes are attached to the steel pipes and, as they corrode over time, they sacrifice themselves to protect the steel. This process is known as cathodic protection and is highly effective in preventing electrolytic corrosion. In addition to coatings and sacrificial anodes, proper insulation and electrical isolation are crucial in protecting steel pipes from electrolytic corrosion. Insulating materials, such as rubber or plastic sleeves, are used to prevent direct contact between the pipes and other metals or electrolytes. Electrical isolation can be achieved through the use of dielectric unions or insulating flanges, which prevent the flow of electric current between different sections of the pipeline. Regular maintenance and inspection also play a key role in protecting steel pipes against electrolytic corrosion. Periodic checks for coating integrity, anode condition, and potential electrical leakage are essential to ensure the continued effectiveness of the corrosion protection system. Overall, a combination of protective coatings, sacrificial anodes, insulation, electrical isolation, and regular maintenance is necessary to protect steel pipes against electrolytic corrosion. By implementing these measures, the lifespan of steel pipes can be significantly extended, ensuring the safety and reliability of various applications such as water distribution, oil and gas transportation, and structural support in buildings and infrastructure.

- Q: What are the different grades of steel used for pipes?

- Pipes are manufactured using various grades of steel, each possessing unique properties and applications. Some commonly utilized grades include: 1. Carbon Steel: This type of steel is widely employed in pipe manufacturing, particularly for low-pressure purposes. It contains a low carbon content, typically less than 0.30%, facilitating easy welding and forming. Carbon steel pipes are known for their durability and cost-effectiveness, making them suitable for diverse industries. 2. Stainless Steel: Stainless steel pipes are renowned for their corrosion resistance and high strength. They consist of an alloy of iron and chromium, with additional elements like nickel and molybdenum enhancing their properties. These pipes find extensive usage in industries such as chemical processing, food production, and oil and gas, where corrosion resistance is vital. 3. Alloy Steel: Alloy steel pipes are created by incorporating elements like manganese, chromium, or nickel into carbon steel. This enhances their strength, hardness, and wear resistance, rendering them appropriate for high-pressure and high-temperature applications. Industries such as power generation, petrochemical, and aerospace frequently employ alloy steel pipes. 4. Duplex Steel: Duplex steel represents a type of stainless steel that combines austenite and ferrite phases. This results in a material possessing exceptional strength, corrosion resistance, and toughness. Duplex steel pipes are commonly utilized in offshore oil and gas platforms, as well as in chemical and petrochemical industries. 5. Low-Temperature Steel: Low-temperature steel is specifically designed to withstand extremely cold temperatures without becoming brittle. These pipes find significant use in industries such as cryogenic storage, LNG transportation, and refrigeration. Choosing the appropriate grade of steel is crucial to ensure optimal pipe performance and longevity. Factors such as temperature, pressure, corrosion resistance, and cost should be taken into account when selecting the steel grade for pipes.

- Q: Can steel pipes be used for sewage systems?

- Yes, steel pipes can be used for sewage systems. Steel pipes are commonly used in sewage systems due to their durability, strength, and resistance to corrosion. They are particularly suitable for high-pressure applications and can withstand the harsh conditions often found in sewage systems. Additionally, steel pipes are relatively easy to install and maintain, making them a popular choice for sewage infrastructure projects.

- Q: How does galvanization protect steel pipes from corrosion?

- Galvanization protects steel pipes from corrosion by creating a protective zinc layer on the surface of the steel. This zinc layer acts as a barrier, preventing moisture and oxygen from reaching the steel, thus inhibiting the formation of rust and corrosion.

- Q: What are the factors affecting the lifespan of steel pipes?

- There are several factors that can affect the lifespan of steel pipes. 1. Corrosion: Corrosion is one of the primary factors that can significantly reduce the lifespan of steel pipes. Exposure to moisture, chemicals, and other corrosive elements can lead to rusting and degradation of the pipe material over time. 2. Environmental conditions: The environment in which the steel pipes are installed plays a crucial role in their lifespan. Extreme temperatures, humidity, and exposure to various weather conditions can accelerate the corrosion process and weaken the pipe structure. 3. Water quality: The quality of the water flowing through the steel pipes can also impact their lifespan. Water with high acidity or alkalinity levels, excessive chlorine, or other contaminants can cause corrosion and deterioration of the pipe material. 4. Installation quality: The way steel pipes are installed can affect their lifespan. Poor installation practices, such as inadequate support or incorrect alignment, can lead to stress points and structural weaknesses, making the pipes more prone to failure. 5. Maintenance and repair: Regular maintenance and timely repairs are crucial in maximizing the lifespan of steel pipes. Proper cleaning, inspection, and corrosion protection measures can help identify and address potential issues before they progress and cause significant damage. 6. Design and material quality: The design and quality of steel used in pipe manufacturing are important factors in determining their lifespan. High-quality steel with appropriate alloy composition and thickness provides better resistance to corrosion and mechanical stress, ensuring a longer lifespan. 7. Load and pressure: The load and pressure that steel pipes are subjected to can impact their durability. Excessive pressure or frequent variations in pressure can put stress on the pipe walls, leading to fatigue or failure over time. By considering and addressing these factors, it is possible to extend the lifespan of steel pipes and ensure their reliable performance over an extended period.

- Q: How do steel pipes perform in marine environments?

- Steel pipes perform well in marine environments due to their high corrosion resistance. They are typically coated with protective layers such as zinc or epoxy, which further enhance their ability to withstand the harsh conditions of saltwater, waves, and constant exposure to moisture. These pipes are capable of withstanding the corrosive effects of seawater, making them reliable for various applications like offshore oil rigs, shipbuilding, and coastal infrastructure.

- Q: Is the steel frame on each floor supporting formwork (floor) called full scaffolding?

- The use of scaffold as its height, when the ceiling height below 3.6M, no matter what the ceiling decoration, decorative scaffolding are calculated

- Q: How are steel pipes transported from the manufacturing site to the construction site?

- Steel pipes are typically transported from the manufacturing site to the construction site through various means, including trucking, rail transportation, and sometimes even by barges or ships for longer distances. The chosen mode of transportation depends on factors such as the distance between the sites, the quantity and size of the pipes, and the available infrastructure.

- Q: Can steel pipes be used for the construction of dams?

- Yes, steel pipes can be used for the construction of dams. Steel pipes are commonly used in dam construction for various purposes such as intake and outlet structures, penstocks, and piping systems for transporting water. Steel pipes offer high strength, durability, and resistance to corrosion, making them suitable for withstanding the water pressure and environmental conditions in dam projects.

Send your message to us

Popular Variety is Complete in Thick Wall Seamless Steel Pipe

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords