Popular Automatic FRP Sheet Making Machine with Low Price Automatically

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Popular Automatic FRP Sheet Making Machine with Low Price Automatically

Product Applications:

The products are widely applied to green house, skylight, porch, door, sandwich panel,ceiling, transportation body, concrete form and liner panels.

Product Advantages:

1.It adopts advanced mechanical structures & technilogy. It has achieved domestic advanced level with advanced technology and reasonable craft, high degree automation and high outputs.

2.It is PLC digital control,including resin feeding.It can achieve vacuum charging resin to doctor blade.Even mixture, easy cleaning and more automation.

3.Easy operation, low noise, obvious electricity conservation, small size, compact structure, low energy consumption, high durability, good looking, etc.

4.Combined with powder collector to absorb the harmful substances to keep the healthy of the worker and prolong the service life of the machine.

5.Increase the operation rate of the material and lower the cost

Main Product Features:

1. Roving chopper speed can be synchronous with the production line.

2. Special cross cutting machine and good synchronization performance make cutting accurately.

3. All the machine parts adopt international standard steel make machine with high stability.

4. System failure can be automatically alarmed and show fault point. Make maintenance easily.

5. Particular parts adopt special purpose wire, durable in use.

Product Parameter:

Product name | Popular Automatic FRP Sheet Making Machine with Low Price Automatically |

Tile Type | PPGI/GI /Aluminumcoil |

Thickness | 0.3-0.7mm |

Material Width | 200-600mm |

Max. forming speed (m/min) | 8-10 m/min |

Main motor power | 5kw |

Hydraulic station motor power (KW) | 8kw |

Voltage | 220v/440v or as the customer require |

Controlling system | PLC( Mitsubishi) |

Dimension ( Length/Width/Height ) | Touch s 8.5*0.8*1.2m |

Total weight (Kg) | About45000kg |

Container required

| 20inch |

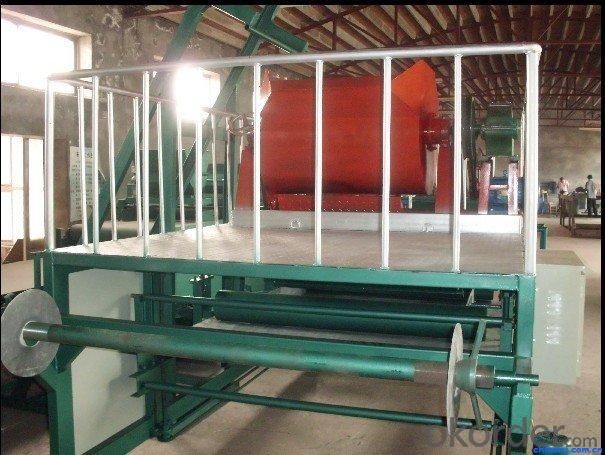

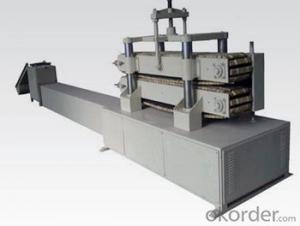

Pictures:

- Q: I need to know where to buy the equipment and what I need to do

- PVC fiber reinforced hose machine is suitable for the plastic flexible pipe, provide first-class service characteristics of pressure liquid conveying water Henan Anyang HuaSu Machinery Manufacturing Co. Ltd. fly for you: the best quality, best price. High output and low power consumption

- Q: Does anyone know any machine for processing plastic products?.

- The injection molding machine, blow molding, rotational molding, thermosetting squeeze a lot

- Q: I'd like to open a plastic bag factory. How much do I need to buy the equipment?

- It depends on what plastic bags you need to make, and the size and size of the big plastic bags are also crucial. I make plastic bags.

- Q: Rubber, plastic, machining specialty, which university is good?

- Dalian Light Industry Institute, Tianjin College of Light Industry, Chengdu University of Science and Technology are good.

- Q: Plastic POM POM generally used for the production of what plastic products?

- Fire regulating ring, support member, gear, rack, rubber wheel, remote control switch bracket, cam pressure bar, cosmetic container, toy car runner, mobile phone chute

- Q: from raw material to particle forming, need several devices, what are they? _?

- I also want to open such a factory, does the profit? I'm using scrap plastic as a particle here, so I want to check it out.

- Q: The main plastic of plastic products

- Polyethylene plastics (Polyethylene) are polymers of ethylene monomers. The raw material for production is oil, coke oven gas or alcohol. Industrial production of polyethylene usually by ethanol dehydration, acetylene catalytic hydrogenation or high temperature cracking. Its commodity name is abbreviated as "B plastic"; the English abbreviation is "PE". Because the density of polyethylene is different, it is divided into low-density polyethylene.[PE (L)], medium density polyethylene [PE (M)] and high density polyethylene [PE (H)].The molecular formula of polyethylene is: (- CH2, CH2 -) n. It is linear in geometry and theoretically has no branched chain and is prone to crystallization. Usually the polyethylene molecule is composed of crystalline and amorphous state in high elastic interlaced region; crystalline polyethylene plastic gives high hardness, strength, chemical stability; amorphous region with polyethylene plastic higher flexibility, toughness, transparency etc.. In fact, polyethylene macromolecules are not absolutely free of branched chains. Its crystallinity is different, density is different, physical and mechanical properties are also different.

- Q: How can we deal with the pollution of waste plastic particles?

- You don't know how much the plastic granulator industry, it is understood that in recent years the development of plastics recycling industry is very rapid, all kinds of plastic granulation machinery are constantly upgrading equipment in energy saving and environmental protection have been greatly improved, for now the sample or engaged in environmental protection and is engaged in waste plastics friend concerns, we explore look.

- Q: shopping bags, what equipment prices? Raw material type and material price? Please expert advice

- It is better to make plastic parts than plastic ones

- Q: What milling cutters are used for processing plastics?

- In fact do not wear too to pay attention to the water to keep up. Try to use high speed low cutting depthThe speed is 8000/, the cut depth is 0.3-0.4, and the 4000 is the best

Send your message to us

Popular Automatic FRP Sheet Making Machine with Low Price Automatically

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches