Popular Automatic FRP Sheet Making Machine of New Design on Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

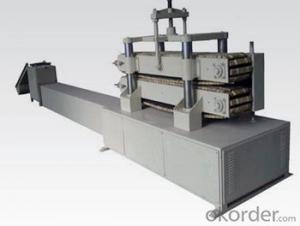

Popular Automatic FRP Sheet Making Machine of New Design on Sale

Product Applications:

The products are widely applied to green house, skylight, porch, door, sandwich panel,ceiling, transportation body, concrete form and liner panels.

Product Advantages:

1.It adopts advanced mechanical structures & technilogy. It has achieved domestic advanced level with advanced technology and reasonable craft, high degree automation and high outputs.

2.Combined with powder collector to absorb the harmful substances to keep the healthy of the worker and prolong the service life of the machine.

3.Increase the operation rate of the material and lower the cost

Main Product Features:

1. Special cross cutting machine and good synchronization performance make cutting accurately.

2. All the machine parts adopt international standard steel make machine with high stability.

3. System failure can be automatically alarmed and show fault point. Make maintenance easily.

4. Particular parts adopt special purpose wire, durable in use.

5. Size and layout of machine can be made according to customer requirements.

Product Parameter:

Product name | Popular Automatic FRP Sheet Making Machine of New Design on Sale |

Tile Type | PPGI/GI /Aluminumcoil |

Thickness | 0.3-0.7mm |

Material Width | 200-600mm |

Max. forming speed (m/min) | 8-12 m/min |

Main motor power | 4kw |

Hydraulic station motor power (KW) | 3kw |

Voltage | 220v/380v or as the customer require |

Controlling system | PLC( Mitsubishi) |

Dimension ( Length/Width/Height ) | Touch s 8.5*0.8*1.2m |

Total weight (Kg) | About45000kg |

Container required

| 20inch |

Pictures:

FAQ:

1)Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world.

2)Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications.

4) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. If you check with okorder, you will see that we have never got any complaint from our customers.

- Q: What machine does the pattern design of this mass produced plastic product use?

- Hello, let me answer the question for you: you can open your mobile phone, Baidu, and then enter your current location, and then enter the address you want to query. The Baidu maps will automatically navigate the nearest route for you.

- Q: What is plastic processing of moulds?

- Although the structure of the mold may be varied because of the variety and performance of plastics, the shape and structure of plastic products and the type of injection machine, but the basic structure is consistent. The mold is mainly composed of pouring system, temperature regulating system, molding parts and structural parts. The gating system and molding parts are in direct contact with the plastic parts and products as plastics and change, is the most complex in the mold, the biggest change, part of the processing requirements of the highest accuracy and smoothness.Pouring system refers to the flow of plastic from the nozzle into the mold cavity, including the main road, cold material hole, diversion channel and gate. Forming parts are parts of the shape of the product, including moving die, fixed mold and cavity, core, forming rod and exhaust port, etc..China plastic mould in promoting high technology driven and pillar industry application requirements, formed a huge industrial chain, from upstream raw materials industry and machining and testing equipment to the downstream machinery, automobile and motorcycle, household appliances, electronic communications, building materials and other major industrial applications, the development of a plastic mold vitality.With the rapid development of China's automotive, home appliances, electronic communications, building materials.

- Q: What plastic products can ABS be used for?

- Because of its good comprehensive properties, ABS plastics have outstanding impact properties and have been widely used instead of metal materials. They are widely used in home appliances, electronic appliances, office equipment, automobiles, machinery and other fields1. home appliances, home appliances, ABS plastic is the largest and most promising areas of application, including television sets, recorders, washing machines, refrigerators, telephones, air conditioners and other shell and internal componentsMade of ABS plastic

- Q: What kind of equipment do you need for plastic basin processing? How much is it?

- For each plastic products, it is necessary to make a set of molds, so the cost of mold production is also a small amount of expenditure, according to the size and complexity of the product is less than ten thousand or twenty thousand, more than tens of thousands or even hundreds of thousands of. The purchase of equipment should be several more.

- Q: Would like to ask a few questions?1, waste plastics need to go through a few devices or steps to become plastic particles2, how much would it cost for the whole set of plastic particles? (I want to get a small wire first)3, if the equipment, plastic material can be any processing?4, is there any pollution in the whole process?.5, how about this prospect this year?Please have experienced predecessors to give some experience

- 3: not for any polypropylene and Juyi plastic processing should be able to use other plastic should not4: the cleaning of this piece in processing will cause two pollution5: This is mainly to see you personally, as the saying goes, peers are different, in general, the plastics industry is OK

- Q: What's the pollution of plastic processing to environmental protection?

- From the ground floor to the surface, to the living to the sky, it is a full range of pollution!

- Q: What mechanical products do you use to make this plastic product?! The more detailed, the better!

- injection molding machineDesign and manufacture moulds are required

- Q: One hundredUrgently!!!Find a kind of plastic that can be used for machining. The better the machining performance, the cheaper the better.Used for the principle model, in the past, when the school practice, used a milky white opaque material, feel good, but I do not know what the name.Copy paste party, do not come to a great God level, experienced best. Kneel thanks!Can PVC be used for machining? As long as you can get on the lathe. If there is a better buy channels.To pipe, diameter 20,40, 65mm 1 each. The lengths are 450450335mm.Can PMMA (acrylic) stick be machined? The supervisor told me that nylon rods do not work and that moisture size is not guaranteed.Then suggest I use this... Which is better than PVC? Thank you

- Plastic pipe on the market PVC find, building materials market is more than, can be mechanical processing. The tool before and after grinding angle of large points, especially the front angle and edge angle, more sharp knife arc.

- Q: tooling mold design, processing, whether the need for quality certification system?

- Management system certification is basically looking at the enterprise's own needs, nor is it mandatory, but if you are here, if useful in the car, you have to do TS certification

- Q: Is there a difference in melt index before and after processing?

- If no additives are added during processing, the melt index is the same as that before processing.

Send your message to us

Popular Automatic FRP Sheet Making Machine of New Design on Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches