Popular FRP Auto Sheet Making Machine with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

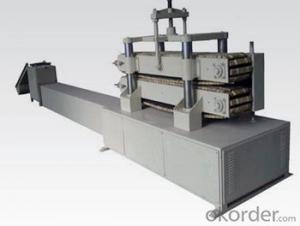

Popular FRP Auto Sheet Making Machine with High Quality

Product Applications:

The products are widely applied to green house, skylight, porch, door, sandwich panel,ceiling, transportation body, concrete form and liner panels.

Product Advantages:

1.It adopts advanced mechanical structures & technilogy. It has achieved domestic advanced level with advanced technology and reasonable craft, high degree automation and high outputs.

2.It is PLC digital control,including resin feeding.It can achieve vacuum charging resin to doctor blade.Even mixture, easy cleaning and more automation.

3.Increase the operation rate of the material and lower the cost

Main Product Features:

1. Roving chopper speed can be synchronous with the production line.

2. Special cross cutting machine and good synchronization performance make cutting accurately.

3. All the machine parts adopt international standard steel make machine with high stability.

4. System failure can be automatically alarmed and show fault point. Make maintenance easily.

5. Size and layout of machine can be made according to customer requirements.

Product Parameter:

Product name | Popular FRP Auto Sheet Making Machine with High Quality |

Tile Type | Matched |

Thickness | 0.3-0.7mm |

Material Width | 200-600mm |

Max. forming speed (m/min) | 8-10m/min |

Main motor power | 6kw |

Hydraulic station motor power (KW) | 3kw |

Voltage | 250v/320v or as the customer require |

Controlling system | PLC( Mitsubishi) |

Dimension ( Length/Width/Height ) | Touch s 6.5*2.8*1.2m |

Total weight (Kg) | About45000kg |

Container required

| 20inch |

Pictures:

FAQ:

1)Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world.

2)Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications.

4) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. If you check with okorder, you will see that we have never got any complaint from our customers.

- Q: What machine does the pattern design of this mass produced plastic product use?

- Hello, let me answer the question for you: you can open your mobile phone, Baidu, and then enter your current location, and then enter the address you want to query. The Baidu maps will automatically navigate the nearest route for you.

- Q: What kind of machinery does it take to open a workshop type plastic product factory? How much is the investment?

- Purchase injection molding machine can, investment an injection molding equipment needs more than ten thousand (generally needs at least two), also need a crusher, thousands of yuan. Mixing machine according to the selection of materials, it is estimated that thousands of yuan. The mold needs several sets, and the price is estimated at around 10 thousand. A small size of 2~3 is enough for 100 square meters. Under their own estimates, the investment!

- Q: How much is the general control of plastic products profit? Thank you

- 20%, the profit specification. Our plastic material only 20% gross profit, the finished product should be more than 20%.

- Q: What is the function of adding filler in the processing of plastic products?

- Physical properties change has come under the situation, but also can reduce the cost

- Q: PC and PC alloy plastic surface effect which better, which good processing, and what are the other differences?

- Compared to PC and PC plastic alloy surface, the effect of course is a good PC, PC water on the surface of the mirror effect, and the processing is good.

- Q: Want to buy an injection molding machine to do some plastic products, equipment about how much money ah? What needs to be prepared?

- More than 100 thousand injection molding, about 10-15, model brand difference, tens of thousands of price difference. In addition, supporting facilities, air pump, cooling tower, burr machine and so on nearly 100 thousand, but also procurement of raw materials costs, site costs, pre operation, investment, etc.. If the injection function is installment, then about 250 thousand can start production.

- Q: How are the plastic products made of this texture processed?

- Plastics processing technologyPlastic forming process. It is a general term for various processes that convert synthetic resins or plastics into plastic products. It is a larger manufacturing sector in the plastics industry. Plastic processing generally includes plastic batching, molding, machining, bonding, modification and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing.Mixed ingredientsPlastic processing of raw materials, in addition to the polymer, usually also added a variety of plastic additives (such as stabilizer, plasticizer, lubricant, coloring agent, reinforcing agent and filler etc.), to improve the performance of molding process and product or reduce the cost of products. The additive and the polymer are mixed and evenly dispersed into powder, also called dry mixed material. Sometimes, the powder is also processed into pellets. The powders and pellets are referred to as synthetic or moulded plastics.

- Q: What chemicals should be used in plastic products?

- Additives mainly in the following categories:OneAntioxidantsAntioxidantUnsaturated double bonds in plastics are absorbed by oxygen atoms, heat and lightCaused by breaking, resulting in free radicals, which cause a chain reaction, so that the molecular chain scission or formation of chain cross-linking,Resulting in lower or weaker strength of plastic products. The function of antioxidants is to delay the oxidation of plasticsBreak down and prolong the life of plastic products. The antioxidants used in the plastics industry can be divided into functions: (One)Inhibitors of oxidative chain reactions, such as alkylphenolAlkylPhenolButyl tolueneButylatedHydroxytolueneAbbreviationBHT) aromatic aminesAromaticAmines) phenyl - -B-Resistant amine(Phenyl-B-Naphthylamine), were of Kun (AlkylQuinoneAlkenyl bisphenol A(AlkyleneBisphenolAlkyl phenol sulfideAlkylPhenolthioetherSalicylic acidBenzene fingerPhenylSalicylateAnd so on) etc.. (

- Q: What equipment? How much money do not.. at first. There are several sets of injection molding machine can be about 2... Mainly plastic injection molding. The ABS PA PE PP PVC... Etc. in this area. Please know that a friend told Kazakhstan. Thank you.

- How big is the product? How big is the injection machine? The machine has been bought. Waste of electricity and high price; the product made by buying small is not good. The injection machine 100 grams may in 6 to 8, in case Taiwan, {brand is not the same, the price difference is very big. } to do PA, if it is enhanced, it is necessary to do special screw and barrel, wear-resistant.

- Q: How do we calculate the cost?

- Four major matters needing attention in investment of recycled plasticsPlastic recycling is a sunrise industry, the country, not only the effective utilization of resources and protect the environment, reduce the white pollution, from 2004 recycled plastics market, considerable benefits, as a new way of friends, is the author contact situation (editor's note), there are many aspects should be prepared in the first period, not to fight the battle without. The main problems are concentrated in the following aspects:1, blind follow-upAccording to the renewable materials market in 2004 prices, had been recycled most of the people have a better income, as for friends, in the test stage, on the surface has the advantages of simple process, low equipment investment, the product basically in short supply, technology content is not high, ordinary people can do at the same time, the raw material is us around the most familiar things, everywhere, everywhere can buy. Rough calculation, such as waste 2000 yuan can receive, the product can sell 4000 yuan, absolutely profitable.

Send your message to us

Popular FRP Auto Sheet Making Machine with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches