Popular And Cheap Hollow Composite Decking

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

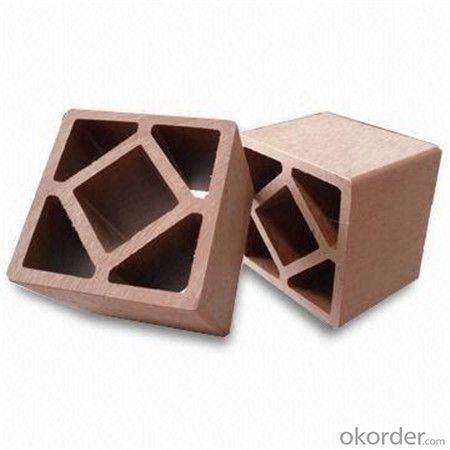

Structure of Popular And Cheap Hollow Composite Decking

| Material | 60%-65% natural wood fiber |

| 30%-35% of eco-friendly HDPE materials | |

| 5% -10% Chemical additivel | |

| Size | 135X25mm,140X25mm,150*25mm,145*30mm,150*30mm |

| Design | Hollow decking |

| Technic | Extruded |

| Length | 3m/pc standard length, also from your required |

| Surface treament | Groove , Woodgrain, Flat, Embossing |

| Color available | Copper Brown, Light Brown, Black, Cedar, Coffee,Dark Grey, Silver Grey, Yellow, Red and Wood,etc. |

| ( we can adjust the new color according to the order requirement) | |

| Cerfiticate | ISO9001,CE, Microbiological testing ,TUV,ect |

| Lifetime | 25years |

| Package | pallet with PVC soft flim |

| Delivery time | 2 weeks(sometimes we have in store) |

| MOQ | 200SQM |

Main Features of Popular And Cheap Hollow Composite Decking

. Eco-friendly, fully recyclable.

. With natural wood grain, color and texture, looks like nature wood.

. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

. Less cracking, less warping.

. No need painting, no glue.

. Can be planed, nailed, drilled and cut to any wanted size.

. Weather resistant, suitable from -40 to 60°C.

. Easy to install, clean.

. Low maintenance, durable, economic, long lifetime

. Anti-slip, less cracking, less warping.

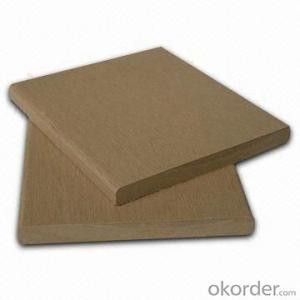

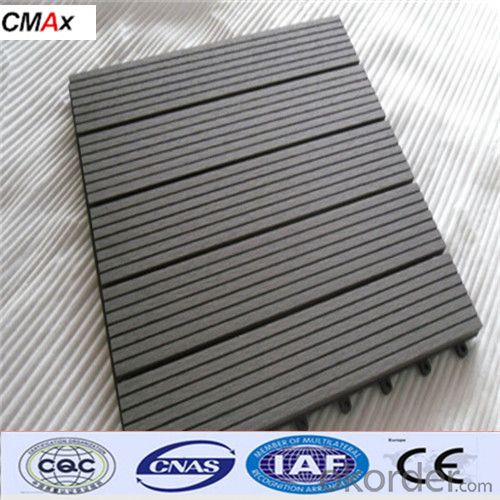

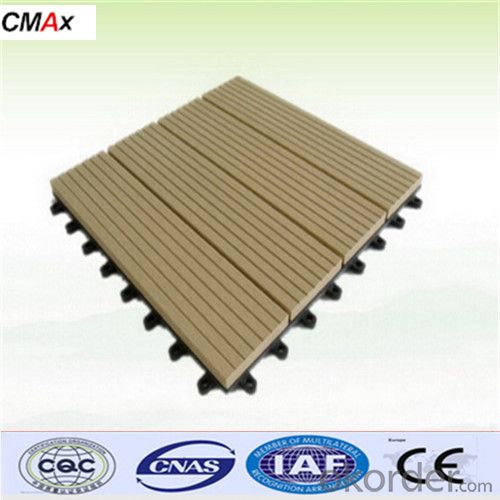

Picture show of Popular And Cheap Hollow Composite Decking

Specification of Popular And Cheap Hollow Composite Decking

Name | Popular And Cheap Hollow Composite Decking |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Popular And Cheap Hollow Composite Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Wood floor moistureproof can use plastic film?

- Moisture proof performance is the most important technical index. Moisture proof performance of the floor, in the geothermal long time, steaming, once there is moisture into

- Q: PVC floor, plastic floor, roll floor, floor leather, the difference between glue

- PVC floorIs a kind of new light ground decoration materials, also known as the "light body material, is widely used, such as families, hospitals, schools, factories, office buildings, public places, supermarkets, commercial, stadiums and other places.

- Q: Basketball court assembled plastic floor why pack

- Expansion and contraction, with a long time will be deformed.

- Q: How to spread plastic floor tiles

- Floor tile shop: cement and sand mixed with water, into a dry and wet dry cement mortar (dry and wet consistency, with hands into a group is not loose). Advance the cushion layer of cement mortar, (using a dry cement mortar ratio three) in accordance with the horizontal exploration shop flat, the brick on the mortar with a wooden hammer tap, carry paimo. Take off the floor brick poured cement paste, and then put the floor tiles can be flat vibration.

- Q: What is the home improvement PVC plastic floor

- Printing film: imported printing layer and the printing layer produced by the domestic production of the color and fidelity is very good, and the general production of small printing layer is prone to fade. Consumers in the purchase of the best looking for a high degree of integrity of the business to buy, so as not to fade the color of the plastic floor, the impact of beauty. Wear resistant layer: due to the different manufacturers, the quality of the wear-resistant layer is also a big difference, the poor quality of the wear-resistant layer in addition to easy cracking is also easy to shrink, resulting in the edge of the floor. Also recommend consumers to find a high degree of integrity of the business to buy PVC floor.

- Q: How to spread the plastic floor?

- With multi-layer solid wood board paved on the floor tile on the line, it is worth noting that the plastic plate is flat buckle

- Q: What are the disadvantages of PVC plastic floor

- If you want to use it, you can consider using it! If you want to know more about PVC plastic floor, you go into the PVC plastic net to see it, this is China's PVC plastic network PVC information and information is the most complete of a PVC industry website. There is no time to go in to see!

- Q: Warm the house, with plastic floor?

- Of course, there is one thing to tell you is that if you choose this floor, we must find authentic professional construction ability to ensure that the service agent to buy. Hair with the ground need to self leveling, the entire construction process should be very professional and very formal, to fully level, otherwise ugly. Now my floor has been used for two years, has not found quality problems. But compared to the advantages and disadvantages of other types of floor is: 1, no stone floor or cold feeling, 2 color, flower type, easy to clean wear many 3 disadvantages: 1, many people think that the lack of a sense of high-end 2, encountered organic solvent pollution is very difficult to clean

- Q: What are the main construction process of laying plastic floor

- (3) plastic floor:Cutting, processing, scraping and wire grass, paste, rolling, curing.

- Q: The family is decorated with the plastic corrugated pipe buried in the floor tiles under the good?

- Well, the principle of the circuit is to change the wall and the top surface. Do not go to the ground, there is danger to go after the wire is to go down, only the water pipes have to go to the ceiling and ground debate

Send your message to us

Popular And Cheap Hollow Composite Decking

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords