Mirafi 140n High Strength Polypropylene Geotextile Hot Seal

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Polypropylene High Strength Geotextile Hot Seal

Geotextile Description

Filament yarn with polyester filament geotextile acupuncture non-woven geotextile, there is a polyester filament geotextile after high-speed needle acupuncture and into cloth products, do not contain chemical additives in the process of needle, also without heat treatment, is environmentally friendly building materials.Can replace the traditional engineering materials and construction methods, construction is more secure, and contribute to environmental protection, can be more economic, effective and lasting to solve basic problems in engineering construction.

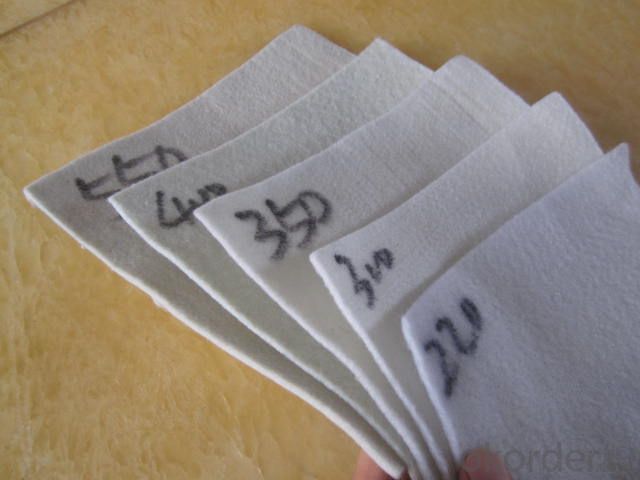

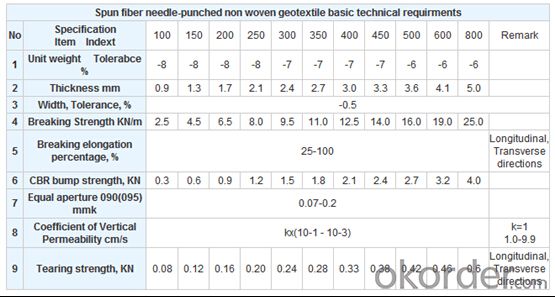

Geotextile Specification

Geotextile Property:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation.

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function.

Geotextile Application:

1. Water conservancy project and hydropower project.

2. Road paving, railway.

3. Airport and port.

4. River bank protection and tunnel

5. Environmental protection, etc.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the applications of geotextiles in geotechnical engineering?

- Geotextiles have a wide range of applications in geotechnical engineering. They are commonly used for soil stabilization, erosion control, and drainage systems. Geotextiles can be used to reinforce soil, preventing slope failures and improving the stability of embankments and retaining walls. They also serve as a barrier against soil erosion by maintaining the integrity of the soil structure. In addition, geotextiles are used for filtration and separation purposes, allowing water to pass through while preventing the movement of fine particles. Overall, geotextiles play a crucial role in enhancing the performance and longevity of various geotechnical structures.

- Q: How do geotextiles help with erosion control in river channels?

- Geotextiles aid in erosion control in river channels by acting as a protective barrier against soil erosion. They are placed along the riverbanks or riverbeds to prevent the loss of soil particles due to water flow. Geotextiles stabilize the soil, increase its resistance to erosion, and promote vegetation growth. Additionally, they allow water to pass through while retaining sediment, thus reducing sedimentation in the river channel.

- Q: What are the different factors to consider for geotextile selection in agricultural applications?

- Some of the different factors to consider for geotextile selection in agricultural applications include the required strength and durability of the geotextile, permeability and filtration properties, resistance to chemicals and biological degradation, compatibility with soil and crops, installation and maintenance requirements, and cost-effectiveness.

- Q: Drainage board geotextile or gravel plus geotextile which water treatment effect is good

- Sure that the drainage board plus geotextile drainage effect is good, but the cost than the gravel Gao Hua Zhi geotechnical materials manufacturers to answer

- Q: Can concrete slabs be placed directly on geotextiles?

- Huazhi geotextile material manufacturers

- Q: Application standard of filament geotextile

- National standard for filament geotextiles GB / T-1998 Geosynthetics Filament anti - sticking acupuncture non - woven geotextiles, the latest standard GB / T - 2008.

- Q: What are the specifications of the garage roof using geotextiles?

- Generally with 200g or 300g, I professional production, wish smooth

- Q: How do geotextiles affect soil properties?

- Geotextiles can have a positive impact on soil properties by improving its stability, filtration, and drainage capabilities. These synthetic fabrics act as a barrier, preventing soil erosion and promoting soil compaction. Additionally, geotextiles can enhance the soil's ability to retain water, aiding in irrigation and reducing the risk of drought.

- Q: Are geotextiles suitable for use in geogrid reinforced soil slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced soil slopes. Geotextiles are commonly used in combination with geogrids to enhance the stability and performance of reinforced soil slopes. Geotextiles provide additional reinforcement, filtration, and separation functions, improving the overall effectiveness and durability of the slope system.

- Q: How do geotextiles help in preventing the migration of fine particles in soils?

- Geotextiles help in preventing the migration of fine particles in soils by acting as a barrier or filter. They are typically placed between different soil layers or as a cover over the soil surface. The geotextile's permeable structure allows water to pass through while retaining the fine particles in place. This prevents soil erosion and the displacement of fine particles, ensuring soil stability and protecting surrounding areas from sediment contamination.

Send your message to us

Mirafi 140n High Strength Polypropylene Geotextile Hot Seal

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords