Thin Film Solar Cells for Sale - Polycrystalline Silicon Solar Cells 156mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 9000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Instruction of Polycrystalline Silicon Solar Cells156mm:

Solar cells is made by solar wafer, it has three categories of solar cell right now, monocrystalline polycrystalline and thin film,

These cells are entirely based around the concept of ap-n junction, which is the critical part of solar module, it is the part that can convert the light energy into electricity, the thickness is from 180um to 200um, with even busbars to conduct electricity, textured cell can decrease diffuse reflection; they are often electrically connected and encapsulated as a module.

Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc.

Solar cells are also usually connected in series in modules, creating an additive voltage.

Connecting cells in parallel will yield a higher current;With high quality and stable quality.

Our Cells can greatly improve the performance of Solar Modules.

Polycrystalline Silicon Solar Cells 156mm Advantage:

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

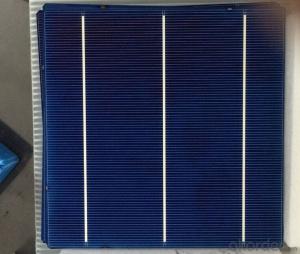

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

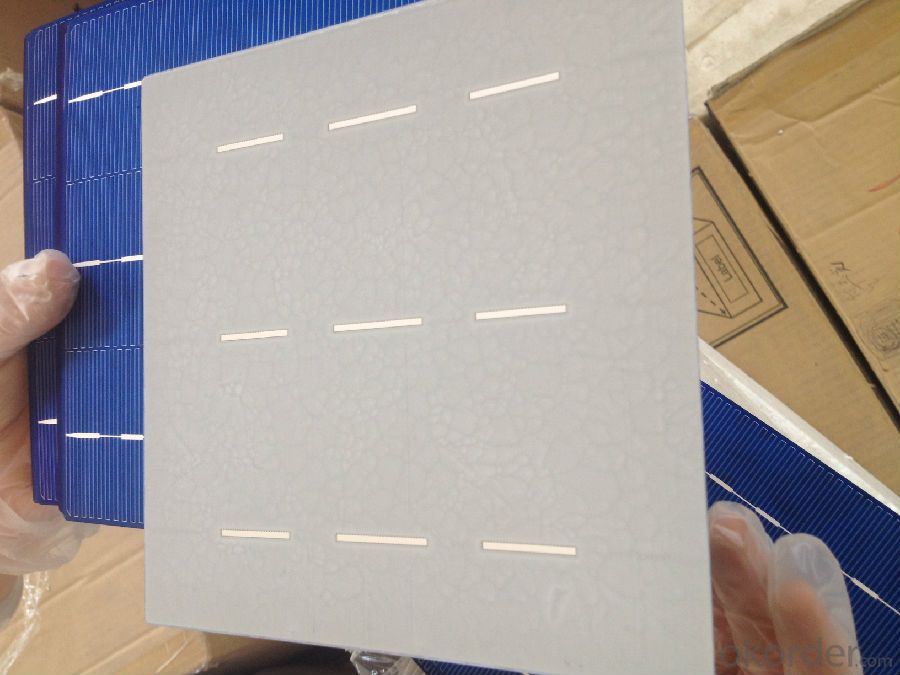

Polycrystalline Silicon Solar Cells Images:

Specification of Polycrystalline Silicon Solar Cells:

Mechanical data and design |

Format - 156 mm × 156 mm ± 0.5 mm |

Thickness- - 200 μm ± 20 μm |

Front (-) - 1.4 mm bus bars (silver),blue anti-reflection coating (silicon nitride) |

Back (+) - 2 mm wide soldering pads (silver) back surface field (aluminium) |

Temperature Coefficient of Cells |

Voc. Temp .coef.%/K -0.364%/K |

Isc . Temp .coef.%/K +0.077%/K |

Pm. Temp. coef.%/K -0.368%/K |

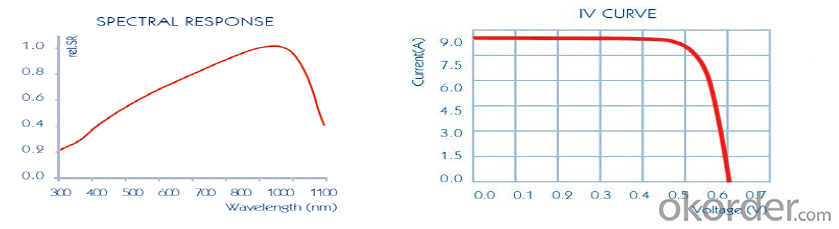

Electrical Characteristic |

Efficiency (%) Pmpp (W) Umpp (V) Impp (A) Voc (V) Isc (A) |

18.00% 4.380 0.538 8.141 0.634 8.740 |

17.90% 4.356 0.538 8.097 0.634 8.725 |

17.80% 4.331 0.537 8.065 0.633 8.710 |

17.70% 4.307 0.536 8.035 0.632 8.695 |

17.60% 4.283 0.535 8.006 0.631 8.680 |

17.50% 4.258 0.534 7.974 0.630 8.665 |

17.40% 4.234 0.533 7.944 0.629 8.650 |

17.30% 4.210 0.532 7.914 0.628 8.635 |

17.20% 4.185 0.531 7.88 -- 0.627 -- 8.620 |

17.10% 4.161 0.530 7.851 0.626 8.605 |

17.00% 4.137 0.529 7.820 0.625 8.590 |

Intensity Dependence |

Intensity [W/m2] Isc× [mA] Voc× [mV] Pmpp |

1000 1.00 1.000 1.00 |

900 0.90 1.000 0.90 |

800 0.80 0.99 0.80 |

500 0.50 0.96 0.49 |

300 0.30 0.93 0.29 |

200 0.20 0.92 0.19 |

IV Curve

FAQ of Polycrystalline Silicon Solar Cells

We have organized several common questions for our clients,may help you sincerely:

①What price for each watt?

It depends on the efficiency of the solar cell, quantity, delivery date and payment terms.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③Can you provide the peripheral products of the solar panels, such as the battery, controller, and inverter? If so, can you tell me how do they match each other?

Yes, we can, we have two companies for solar region, one is CNBM International, the other is CNBM engineering Co.

We can provide you not only the solar module but also the off grid solar system, we can also provide you service with on grid plant.

④What is your warranty of solar cell?

Our product can promise lower than 0.3% open box crack, we support claim after opening the box if it has crackm color difference or sth, the buyer should give pictures immediately, we can not accept the claim after the solar cell has assembled to solar panel.

• Timeliness of delivery

• ⑤How do you pack your products?

We have rich experience on how to pack the solar cell to make sure the safety on shipment, we could use wooden box or pallet as buyer's preference.

⑥ Can you do OEM for us?

Yes, we can.

- Q: Can solar cells be used for powering electric water heaters?

- Yes, solar cells can be used for powering electric water heaters. Solar panels generate electricity from sunlight, which can then be used to power electric water heaters. This is an eco-friendly and cost-effective way to heat water using renewable energy sources.

- Q: Are solar cells affected by pollution?

- Solar cells can be affected by pollution, particularly air pollution, as it can reduce the amount of sunlight that reaches the cells. This can result in a decrease in their efficiency and overall energy production. However, regular cleaning and maintenance can help mitigate the impact of pollution on solar cell performance.

- Q: What is the maintenance required for solar cells?

- The maintenance required for solar cells is typically minimal. It involves regular cleaning of the solar panels to remove any dust or debris that may accumulate and potentially reduce their efficiency. Additionally, periodic inspections are recommended to detect any signs of damage or wear, such as cracked glass or loose connections, which should be repaired promptly. Overall, proper maintenance ensures optimal performance and longevity of solar cells.

- Q: Briefly explain why solar cells are made into components

- The electrical performance parameters of solar cells are: voltage, current, capacity, type, charging rate and so on. The voltage parameter of the battery refers to the operating voltage of the battery, that is, the voltage that can be supplied to the device. Current, refers to the maximum discharge current of the battery. Capacity, refers to the total discharge power of the battery, with An / hour (A / H) said.

- Q: How much does a solar cell weigh?

- The weight of a solar cell can vary depending on its size and design. On average, a standard solar cell weighs between 3 to 4 ounces (85 to 113 grams).

- Q: What is the role of solar cells in powering outdoor lighting?

- The role of solar cells in powering outdoor lighting is to convert sunlight into electricity. Solar cells, also known as photovoltaic cells, capture the sun's energy and convert it into usable electrical power. This power is then stored in batteries, which can be used to illuminate outdoor lights during the night. Solar cells eliminate the need for traditional electrical power sources, making outdoor lighting more environmentally friendly and cost-effective.

- Q: I know that solar cells are produced by DC and then converted into alternating current through the inverter, who explains why the solar cell is produced by DC?

- The sun is irradiated on the semiconductor p-n junction to form a new hole-electron pair. Under the action of the p-n junction electric field, the holes flow from the n region to the p region.

- Q: What is the role of anti-reflective coatings on solar cells?

- The role of anti-reflective coatings on solar cells is to reduce the amount of light reflection and increase the amount of light absorption by the solar cell. This helps to improve the overall efficiency of the solar cell by allowing more light to be converted into electricity.

- Q: How do solar cells impact wildlife?

- Solar cells have a minimal impact on wildlife compared to other forms of energy generation. While the installation and maintenance of solar panels can disrupt local habitats temporarily, once operational, solar cells do not produce air or water pollution, noise, or hazardous waste that could harm wildlife. Additionally, solar farms can provide valuable habitats for certain species, as the spaces between panels can be used for vegetation growth. Overall, solar cells are considered a much cleaner and safer energy option for wildlife compared to traditional fossil fuels.

- Q: Can solar cells be used in electric vehicle charging stations?

- Yes, solar cells can be used in electric vehicle charging stations. Solar panels can capture sunlight and convert it into electricity, which can then be used to charge electric vehicles. This approach is known as solar-powered charging stations and is an environmentally friendly alternative to traditional grid-powered stations.

Send your message to us

Thin Film Solar Cells for Sale - Polycrystalline Silicon Solar Cells 156mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 9000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords