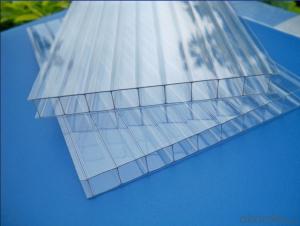

Polycarbonate Hollow Sheet Ultraviolet Resistance: With UV Protective Layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

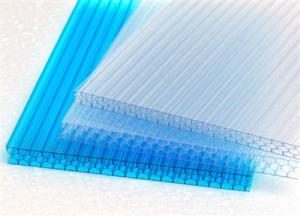

1, Light Transmisson

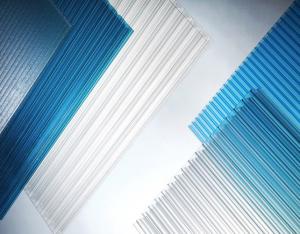

The light transmission reaches 12%-82% depending upon colour and thickness.

2, Thermal Insulation

Proprietary hollow from contributes to reduce the energy consumption and therefore energy costs.

3, Fire Retardancy

According to GB8624-1997 the fire retardant classification of POLYGAL project sun sheet is B1.

4, Impactresistance

Its outstanding toughnes offers greater protection against breakage during transportation, installation and usage. The impact strength is 10-27 times as much as plexiglass.

5, UA-Protection

Attrbuting to the proprietary UV surfaces. Remain perfact mechanical andoptical properties after exposed to extreme weather for a long time.

6, Sound Insulation

The hollow from and polycarbonate resin offer significant advantage to the sound insulation.

7, Weather Ability

It have good weather ability can maintain excellent properties in a wide temperature range form -40* to 120*.

8, Easy installation

Easy installation can be cold bent.

Features:

1) Light transmission: Up to88%

2) Impact resistance: 80 times that of glass, 15 times that of acrylic sheeting

3) Temperature resistance range: -40 ~ 120°, C

4) Light weight: Only 1/12 of the weight of glass of the same thickness

5) Ultraviolet resistance: With UV protective layer

6) Flame resistance: Rated class B1

7) Sound and heat proof

Applications of our products:

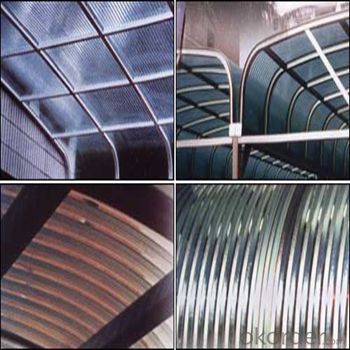

1) roofing for swimming pool, shopping malls, commercial streets

2) Sunshade for stadiums and bus stops, gazebo, open air carport,

2) lighting canopy for corridors, passages and subway entries

3) flashing for bank ATMs, telephone box, gateways, garages

4) Sound and heat insulation wall for expressways and houses

5) Heat preservation material for agricultural greenhouse, flower greenhouse.

6) Soundproof material for partitions

7) Unbreakable material for glazing widows, roof glazing

Key Features:

High impact strength.

Virtually unbreakable over a wide temperature range (-20°C to 120°C), able to withstand shattering, cracking, crazing or even breaking.

High light transmission-high degree of light transmission while blocking harmful Ultra Violet rays.

Design freedom - lightweight, highly flexible, easy to fabricate on site. Can be easily cold formed and will not crack or splinter when fabricated.

Good fire characteristics - self extinguished material. The sheet does not contribute to flame spread. When subjected to flames from spreading fire, the material only melts away and form holes which releases smoke, gases and heat. It does not emit toxic gases.

Excellent weather ability-I side UV co-extruded, to give longer lifespan of material.

10 years limited warranty - against discoloration, loss of light transmission, and loss of strength due to weathering.

- Q: How to correctly identify the quality of pc sunshine board and pc durability plate method

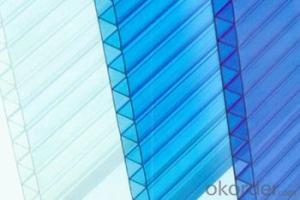

- Comparative, can be a few transparent sun panels compared to the side, if the sun side of the board looks more transparent color, indicating that the sun can still plate. Can also be more thickness, the general manufacturers say 8 thickness, his actual thickness will not be less than 7.7MM.

- Q: Who can tell me, plastic hollow board and PC sun board in the end what is the difference?

- Compared with the traditional ordinary film, it has the following advantages: ?1. Transparency reached 81%, has to keep up with ordinary film, can be planted on the promotion of vegetables. 2. Double-layer hollow structure, greatly weakened the strong exchange of hot and cold air, the greenhouse was basically in the state without dripping, greenhouse less mist, indoor relative humidity at a long time below 80%, greatly reducing the disease of the planted. 3. Double-layer hollow structure, good temperature effect, the thermal energy storage capacity of solar energy is strong, slow greenhouse temperature at night, are high-temperature covering materials. There are documented proofs that are 2 ° C higher than the temperature of the traditional shed. 4. Double hollow structure, the middle of the ribs, wind, snow pressure ability, not easy to tear. 5. Long life, do not have to replace each year, save hours, flowers, aquatic products, livestock and other greenhouse, has been used for more than 10 years of records. 6, due to the many advantages of the above, and after more than ten years of natural weather resistance test, so we believe that double insulation film (PE sun board) can be China's agriculture, animal husbandry (pig, chicken, raise Ducks, cattle, sheep, special breeding, etc.) aquaculture, flower planting, forestry nursery, etc., the construction of many low-cost, low humidity, long life, high-quality high-quality solar greenhouse.

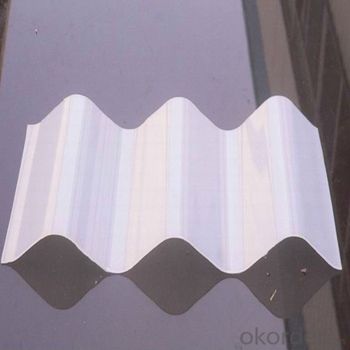

- Q: Pc sun panels and frp lighting board what are the two differences

- Pc sun plate is a polycarbonate material hollow board used in outdoor building lighting top to achieve anti-ultraviolet, weather, anti-aging effect.

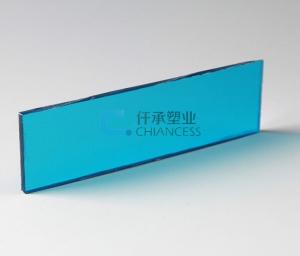

- Q: What is the difference between PC stamina and PC sunboard?

- In fact, from their nickname we can simply distinguish, PC sun plate is also called hollow board, hollow board, as the name suggests is the middle is hollow. PC Nai Liban also known as solid board, of course, is solid.

- Q: PC Nai Liban and Sunshine board Which domestic manufacturers of the best products?

- Self-confidence from the progress, we Jia Sida production of sun panels and durability plate quality can be guaranteed

- Q: PC sun panels and color steel plate how to bond

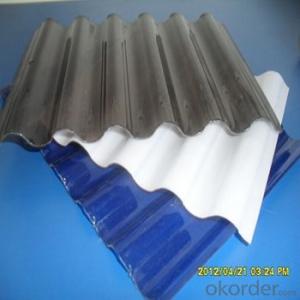

- The use of sealant at the junction, with self-tapping screws fixed on the purlins. Transparent sun panels and insulation color plates are two different roofs. The sun panels are mainly made of PC / PET / PMMA / PP. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly. Color steel plate, refers to the color coated steel plate, color coated steel plate is a kind of organic coating with steel plate. Color steel plate is divided into veneer, Caigang composite board, floor board and so on. Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs.

- Q: How much of the installation of the sun board installation of a square meter

- The sun panels are mainly made of PC / PET / PMMA / PP. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly.

- Q: Project sun board price how much

- PC sunshine board price is calculated per square meter as follows: Thickness of 6mm - 16mm, the general price of 25 yuan -100 yuan / ㎡, the thickness of the sunshine plate is more commonly used, the structure is divided into two layers, three, four, X type, meter type, honeycomb type.

- Q: Can the sun board cover the bedroom?

- Sun panels can cover the bedroom, the sun board mainly by the PC / PET / PMMA / PP material production. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly.

- Q: What are the differences between plastic endurance boards and sun panels?

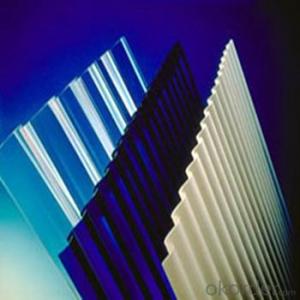

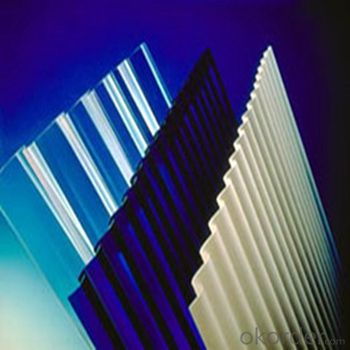

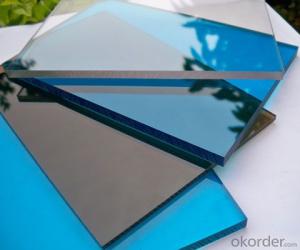

- Color: transparent, blue, green, creamy, brown, gray.

Send your message to us

Polycarbonate Hollow Sheet Ultraviolet Resistance: With UV Protective Layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords