Polycarbonate Hollow Sheet Ultraviolet Resistance with UV protective layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

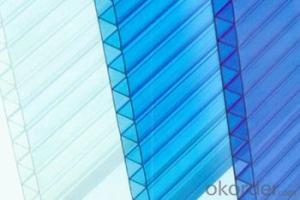

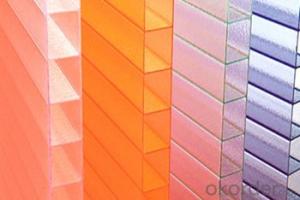

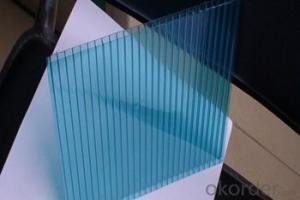

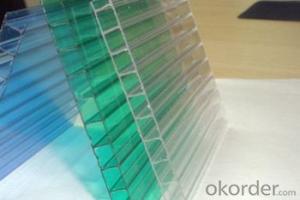

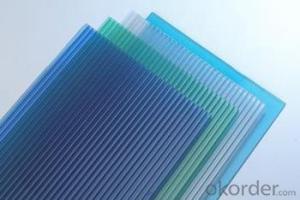

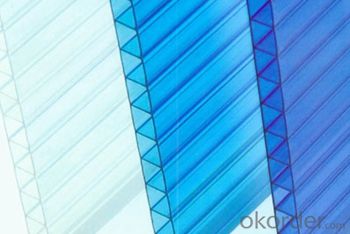

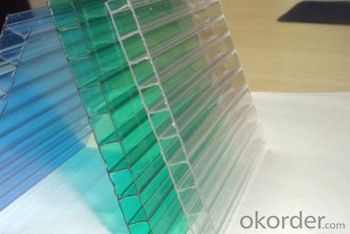

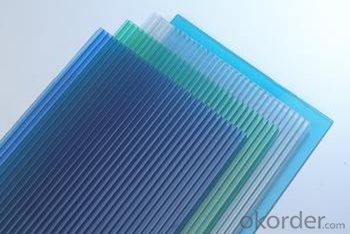

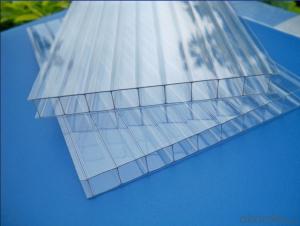

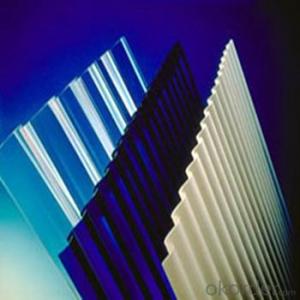

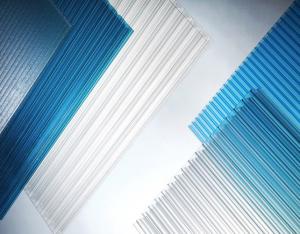

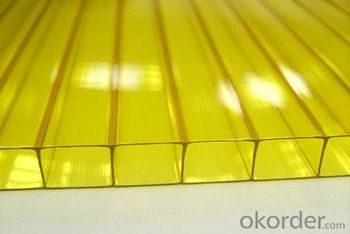

Polycarbonate three wall hollow sheet

Thickness: 10mm / 12mm / 14mm / 16mm

Width: 2100mm

Length: 5800mm / 11800mm

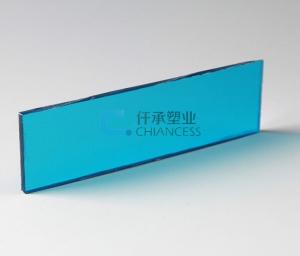

Colors: Clear, Opal, Green ,Blue, Bronze , Lake-blue ,

Note : Special specification and color can be processed against customer's demand.

Key Features:

High impact strength.

Virtually unbreakable over a wide temperature range (-20°C to 120°C), able to withstand shattering, cracking, crazing or even breaking.

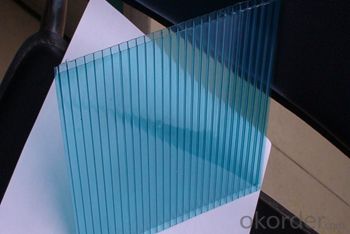

High light transmission-high degree of light transmission while blocking harmful Ultra Violet rays.

Design freedom - lightweight, highly flexible, easy to fabricate on site. Can be easily cold formed and will not crack or splinter when fabricated.

Good fire characteristics - self extinguished material. The sheet does not contribute to flame spread. When subjected to flames from spreading fire, the material only melts away and form holes which releases smoke, gases and heat. It does not emit toxic gases.

Excellent weather ability-I side UV co-extruded, to give longer lifespan of material.

10 years limited warranty - against discoloration, loss of light transmission, and loss of strength due to weatheri

Applications of our products:

1) roofing for swimming pool, shopping malls, commercial streets

2) Sunshade for stadiums and bus stops, gazebo, open air carport,

2) lighting canopy for corridors, passages and subway entries

3) flashing for bank ATMs, telephone box, gateways, garages

4) Sound and heat insulation wall for expressways and houses

5) Heat preservation material for agricultural greenhouse, flower greenhouse.

6) Soundproof material for partitions

7) Unbreakable material for glazing widows, roof glazing

FAQ

1. Q: How can I get a sample?

A: FREE SAMPLE can be sent to you .Freight will be paid.

2. Q: Would you please tell me the company have business relations which countries?

A: Our products are exported to North America, South America, Europe, the middle-south Asia, the Middle East, etc., and have good market in these places.

3. Q: How do you make our business long-term and good relationship?

A: We keep good quality and competitive price to ensure our customers benefit ;

Product Pictures

Factory Pictures

- Q: PE sun panels and PC sun panels are different

- PC temperature some, much better transparency, PE is not temperature, transparency in general. PE price is about twice as low.

- Q: Who can tell me, plastic hollow board and PC sun board in the end what is the difference?

- Compared with the PC sun panels, it has the following advantages: The price is cheap, it's only one-third the price of a PC sunshine board. ?? Plastic hollow board for the software structure, roll packaging can be transported, saving shipping. Veneer area, the largest can be made 200m2 each (100 meters long × 2 meters wide). Easy to install greenhouse, greenhouse low cost. Long life, more than 10 years of the greenhouse is still in use.

- Q: What is the difference between PC stamina and PC sunboard?

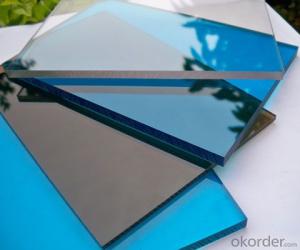

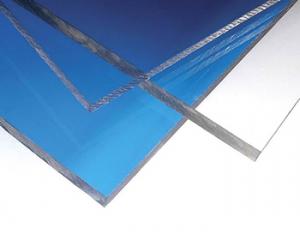

- The easiest way to do this is to compare one or more of the sun panels with the stamina. The difference is obvious, from the structural distinction, PC sun panels have a single layer, double, and even multi-layer and is hollow. PC Nai Liban is single layer solid. From the weight of the distinction, because the sun is hollow, the material is relatively small, so the same thickness and area of the endurance plate much heavier than the sun.

- Q: Where the PC stamina board and the sun board sell more price is also cheaper

- Not the cheapest, only cheaper, but the life is slightly shorter.

- Q: What is the difference between the PC and the PC board?

- Pc stamina board and PC particle board belong to the solid plate, the difference is that the endurance plate is very smooth, and the particles that the diamond is like a rugged.

- Q: Can sunscreen be insulated at night? PC sunshine board insulation performance how?

- Sunshine board due to the special anti-ultraviolet protective layer of hollow structure, can effectively reduce the heat loss, so there is a certain night of the role of insulation, so that greenhouse temperature to maintain a certain range of constant temperature.

- Q: What can I do with my own sunshine board?

- PC sunshine board product range 1, office buildings, department stores, hotels, villas, schools, hospitals, sports venues, entertainment centers and public facilities of the lighting ceiling 2, the highway highway viaduct noise barriers 3, agricultural greenhouse, flower greenhouse and indoor pool of the sky 4, subway entrance, station, parking lot, shopping malls, pavilions, restrooms, corridors and other canopy 5, bank anti-theft counters, jewelry store anti-theft window, police explosion shield 6, advertising light boxes, bus station panels, advertising display cards 7, office, home indoor partition, pedestrian access, fence, balcony, shower and so on

- Q: Lighting board and sunshine board which is good?

- This can not say which is better, can only say which product is suitable for you to use, the general enterprise plant lighting with lighting panels, and some flower room on the temperature requirements of the more stringent must use sun panels and shade net supporting the use.

- Q: Company pc sunshine board how to solve the problem

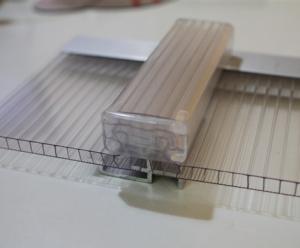

- Two layers of waterproof treatment: sun board endurance board joints with a wide aluminum alloy bar, in the pressure below the bonding of special waterproof tape, and then use a good quality neutral sealant on both sides of the pressure to play the thickness of 5 mm width 5 -8 mm silicone.

- Q: What are the differences between plastic endurance boards and sun panels?

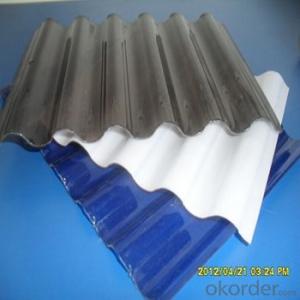

- Category: PC board is generally single and double board, in addition to multi-layer board, wave plate, film.

Send your message to us

Polycarbonate Hollow Sheet Ultraviolet Resistance with UV protective layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords