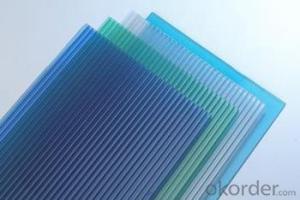

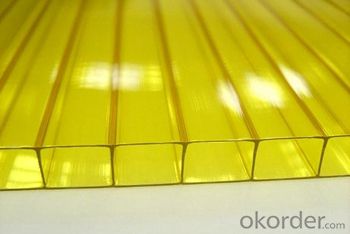

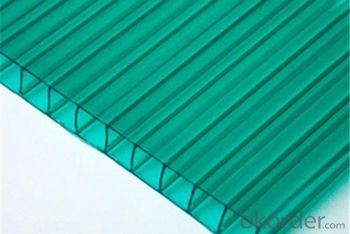

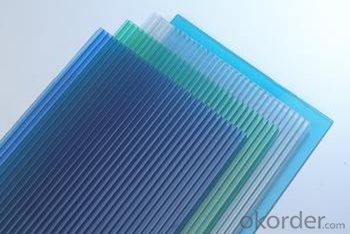

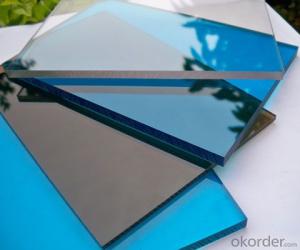

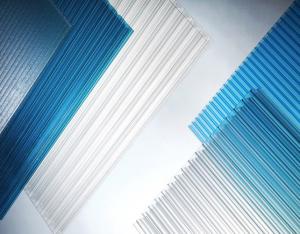

Polycarbonate Hollow Sheet Ultraviolet Resistance: With UV Protective Layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 880000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

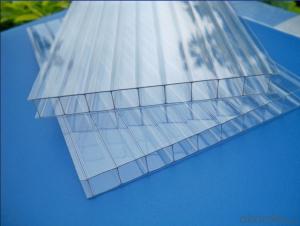

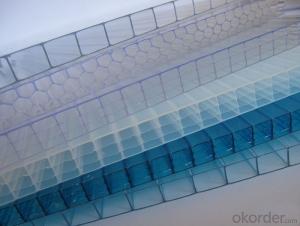

Features:

1) Light transmission: Up to88%

2) Impact resistance: 80 times that of glass, 15 times that of acrylic sheeting

3) Temperature resistance range: -40 ~ 120°, C

4) Light weight: Only 1/12 of the weight of glass of the same thickness

5) Ultraviolet resistance: With UV protective layer

6) Flame resistance: Rated class B1

7) Sound and heat proof

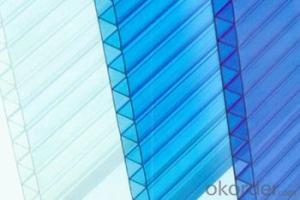

Applications of our products:

1) roofing for swimming pool, shopping malls, commercial streets

2) Sunshade for stadiums and bus stops, gazebo, open air carport,

2) lighting canopy for corridors, passages and subway entries

3) flashing for bank ATMs, telephone box, gateways, garages

4) Sound and heat insulation wall for expressways and houses

5) Heat preservation material for agricultural greenhouse, flower greenhouse.

6) Soundproof material for partitions

7) Unbreakable material for glazing widows, roof glazing

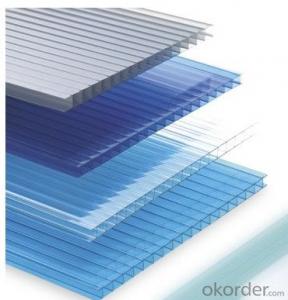

Key Features:

High impact strength.

Virtually unbreakable over a wide temperature range (-20°C to 120°C), able to withstand shattering, cracking, crazing or even breaking.

High light transmission-high degree of light transmission while blocking harmful Ultra Violet rays.

Design freedom - lightweight, highly flexible, easy to fabricate on site. Can be easily cold formed and will not crack or splinter when fabricated.

Good fire characteristics - self extinguished material. The sheet does not contribute to flame spread. When subjected to flames from spreading fire, the material only melts away and form holes which releases smoke, gases and heat. It does not emit toxic gases.

Excellent weather ability-I side UV co-extruded, to give longer lifespan of material.

10 years limited warranty - against discoloration, loss of light transmission, and loss of strength due to weathering.

FAQ:

1. Q: Your company can product how many different kinds of Polycarbonate Sheet Sunshine Board?

A: Our company now have following several products: Glittering Polycarbonate Sheet, Multi-wall Structure Polycarbonate Sheet, Greenhouse Polycarbonate Sheet, General Polycarbonate Solid Sheet, Advertising Polycarbonate Sheet, Polycarbonate Embossed Sheet, Polycarbonate Frosted Sheet, Soundproof Polycarbonate Sheet, Greenhouse Polycarbonate Sheet etc.

2. Q: .What will happen in the event of a fire?

A: Fire safety is one of polycarbonate's strong points. Polycarbonate sheeting is flame retardant and do not emit toxic substances, which is why they are so often incorporated in public buildings.

Factory Pictures

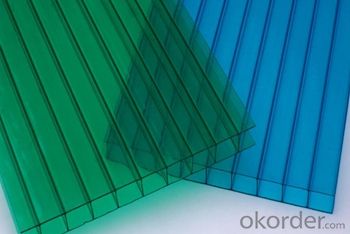

Product Pictures

- Q: What is the difference between sun panels and plexiglass?

- Plexiglass is PMMA polymethyl methacrylate material, commonly known as acrylic. Transmittance of 92%. ??? Not spontaneous combustion but is flammable, do not have self-extinguishing. ??? The average hardness of the Rockwell hardness of about 8,9 degrees. ??? Heat resistance is not high, continuous use temperature exceeds 90 ℃ will heat deformation. ??? Cold resistance is also poor, brittle temperature of about 9.2 ℃.

- Q: How to correctly identify the quality of pc sunshine board and pc durability plate method

- Pull the protective film to see the sheet. Particles or bubbles are relatively small or relatively small, indicating that the recovery of raw materials, but is a good back to the material, this board is the middle grade plate. Such as bubbles and particles more or larger, indicating that the poor raw material, this board is a low-grade plate. If the civilian particles or particles rarely, that the quality of the sun plate is very good, is ten years of quality.

- Q: Pc sun panels and frp lighting board what are the two differences

- Frp lighting board is translucent glass fiber material used in the top of the translucent lighting state price advantage. Two products sunshine board advantage beautiful and environmentally friendly non-toxic pollution-free, frp advantage of low cost See what kind of project you use, how many squares your area.

- Q: Sunny plate that is a transparent that I want to use the home screen 4mm thickness can be about how much a square

- Generally solid and transparent is the stamina board, do the bath on the screen in general 3mm, 4mm can, the specific price depends on what you need the quality of the

- Q: PC sunshine board, what material, what kind of good

- If you want to use their own cost-effective relatively high we can choose 10mm quality better, this kind of sunshine board in the normal situation is to allow people not often walk in the above. But for 8mm or 6mm sun panels, if people go in the above or want to shelf life for a long time there may be a safe use of hidden dangers.

- Q: What is the difference between the PC and the PC board?

- Two products are the same material, but the production process is not the same, the price is generally the same circumstances

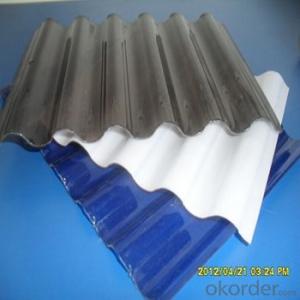

- Q: What is the difference between sun panels and lighting panels?

- Matching FRP lighting panels can be customized with the roof color plate exactly match the cross-section, and low cost, convenient and fast. PC board is based on the main plate, the specifications of more thickness, can be a good choice for their own sun panels, easy installation, fast.

- Q: What can I do with my own sunshine board?

- Can make their own small greenhouse room, the balcony can be used to do sunrise sun awning.

- Q: Lighting board and sunshine board which is good?

- This can not say which is better, can only say which product is suitable for you to use, the general enterprise plant lighting with lighting panels, and some flower room on the temperature requirements of the more stringent must use sun panels and shade net supporting the use.

- Q: What is the difference between the sunboard and the Capron board?

- Sunshine board and the essence of Kaplan is different from the call at home and abroad, like foreign call Capron, domestic call the sun board, Zhejiang Evonik, take you into the PC plate world, distinguished quality, made the world brand.

Send your message to us

Polycarbonate Hollow Sheet Ultraviolet Resistance: With UV Protective Layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 880000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords