Plywood Film Faced Plywood Commerical Plywood

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

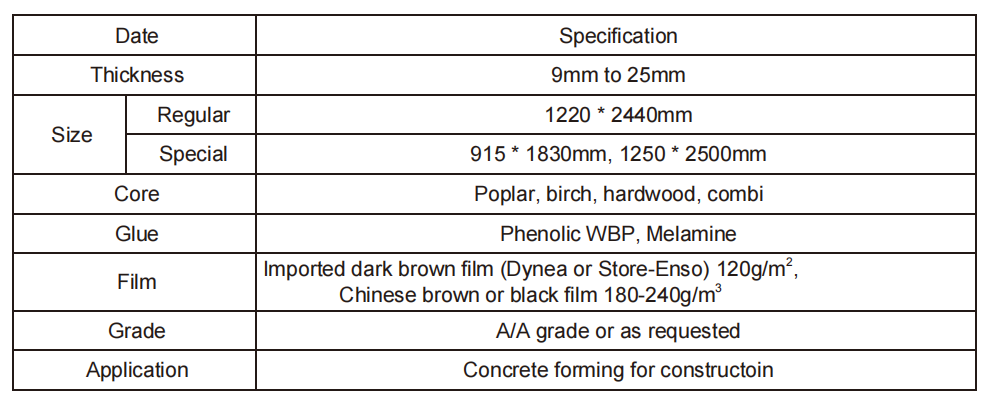

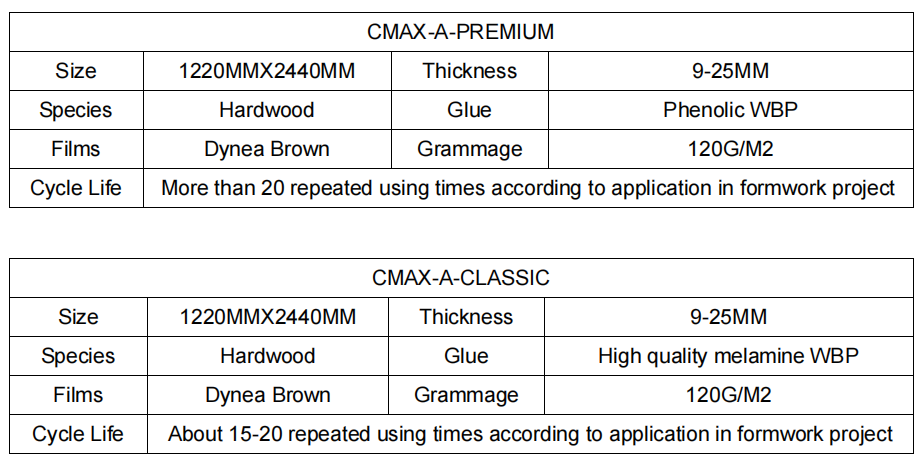

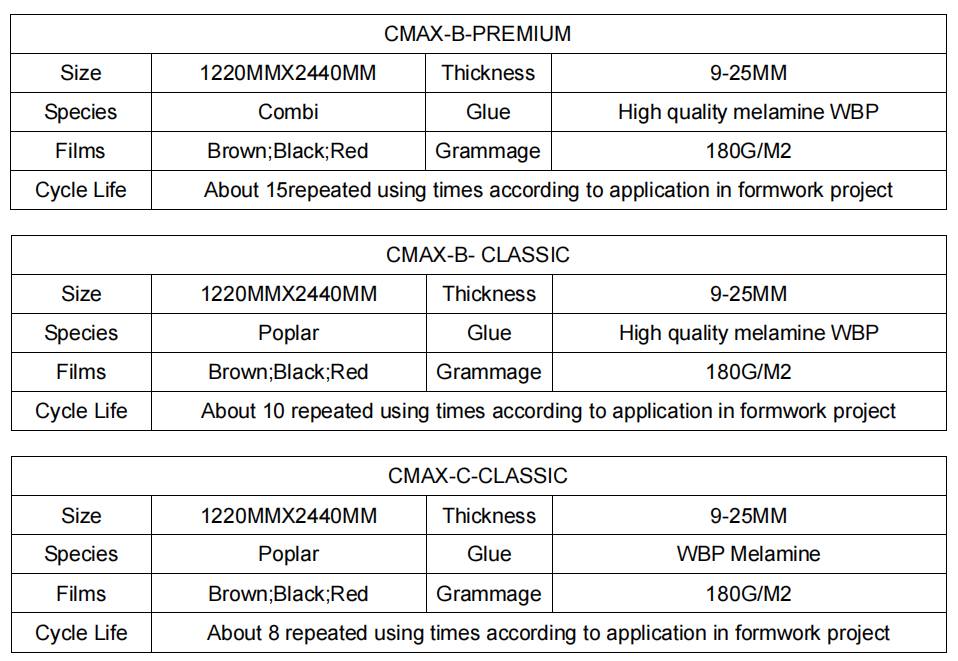

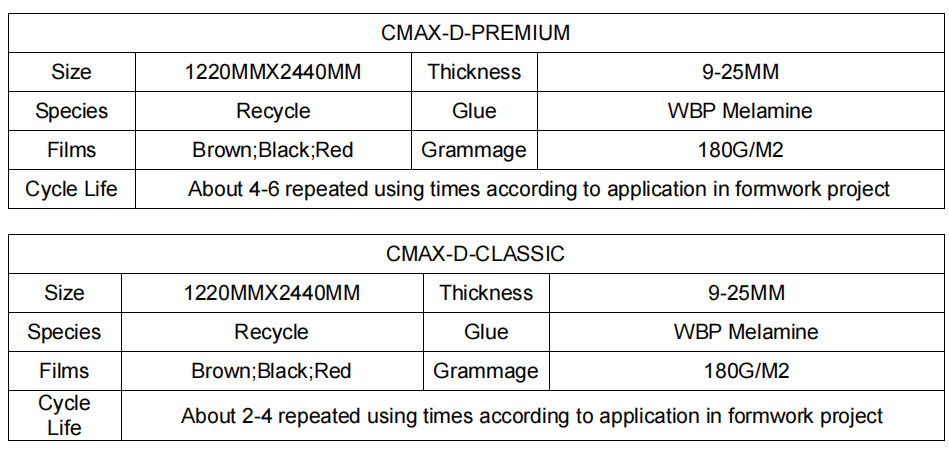

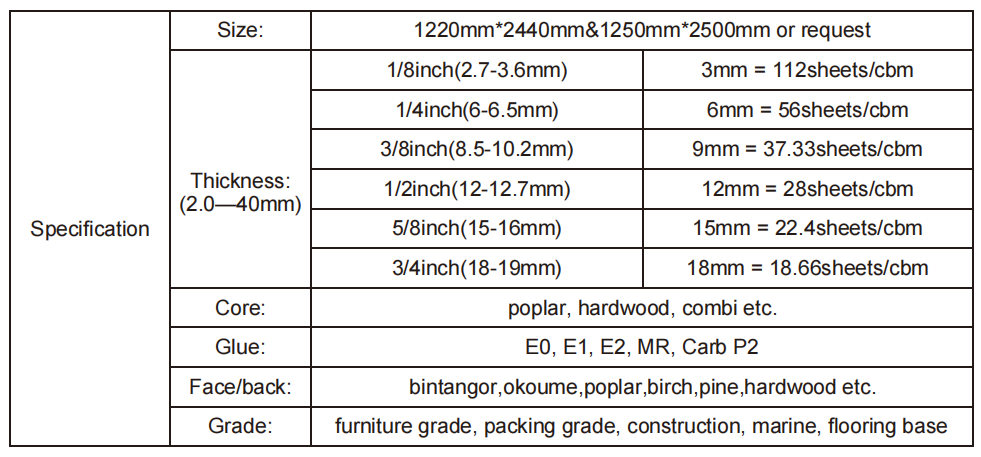

Specification

Plywood is a versatile engineered wood product made by bonding thin layers or "plies" of wood veneer together. Each layer is glued with the grain at right angles to the adjacent layer, enhancing its strength and stability. This cross-graining technique minimizes wood's natural tendencies to split, warp, or shrink, making plywood an ideal choice for various applications. We offer a range of high-quality plywood products to meet diverse needs: Film Faced Plywood、Commercial Plywood、Fancy Plywood.

Application

Plywood is widely used across numerous industries due to its strength, durability, and versatility. In construction, it serves as a primary material for concrete formwork, flooring, roofing, and walls. The furniture industry utilizes plywood for making cabinets, tables, chairs, and other pieces. Plywood is also essential in interior design for paneling, decorative finishes, and architectural elements. Additionally, it is used in packaging, vehicle interiors, and boat building, showcasing its adaptability to various needs.

Advantages

Strength and Stability: Plywood's cross-grained construction provides exceptional strength and stability.

Versatility: It can be tailored to suit a wide array of applications, from structural to decorative.

Cost-Effectiveness: Plywood offers a more economical option compared to solid wood.

Environmental Sustainability: It makes efficient use of wood resources and can be sustainably sourced.

Ease of Use: Plywood is easy to cut, shape, and install.

Parameter

Film Faced Plywood

Commerical Plywood

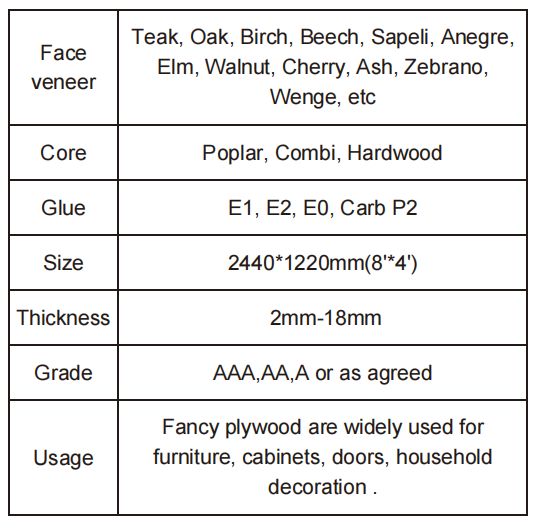

Fancy Plywood/Decorative Plywood

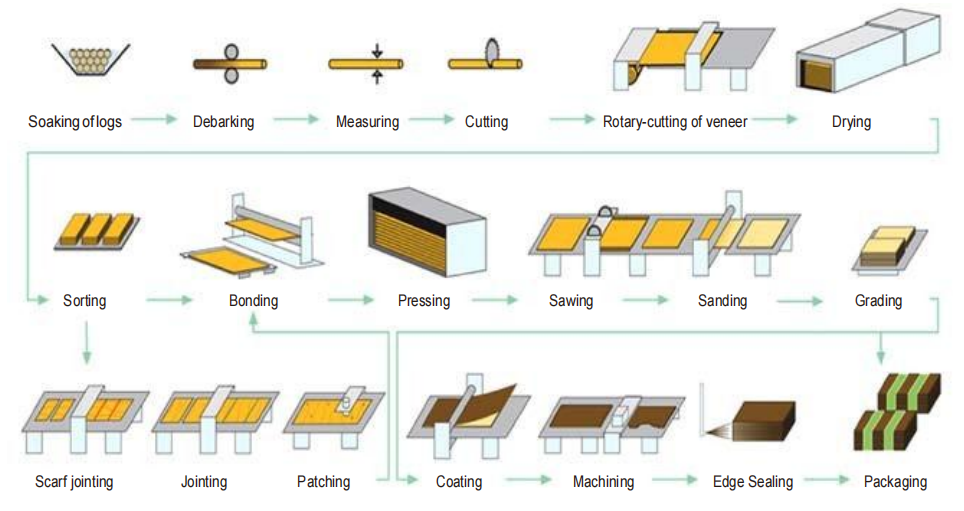

Manufacturing Process

- Q: Plywood in the material defects?

- resin leakage (resin) resin streak trees after the local injury, the resin gathered in a large number of them and through the surrounding wood and the formation of color than the surrounding normal wood deep

- Q: The structure of the plywood at the same time meet two basic principles

- the front panel is called the panel, the back of the table is called the back plate; the core

- Q: What are the further processing of plywood?

- Curved plywood cutved plywood Plywood that has been bent once or several times.

- Q: What plywood is now commonly used?

- According to the different composition of the glue, for the construction of plywood with the following types of glue:

- Q: The Preparation of plywood ingredients

- Loose loose side In the process of peeling or slicing, the side of the board and the knife contact side, this side due to reverse expansion and often produce a bottle peeling or cut fissure.

- Q: What are the defects in plywood material?

- Fissure check The short separation of the panel fiber usually does not start from the side of the board, not all extending through the thickness of the veneer.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- It is usually made of odd-numbered veneers and The fibers of the adjacent veneers are perpendicularly bonded to each other

- Q: What kind of glue is today's plywood?

- if you want to make outdoor use of wood products, you can use E1 grade (or even E0 level) phenolic glue.

- Q: What are the shortcomings of plywood

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

- Q: What are the plywood specifications?

- International Organization for Standardization of ordinary plywood production, from the structure, finished product moisture content, quality 3 to make the provisions:

Send your message to us

Plywood Film Faced Plywood Commerical Plywood

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords