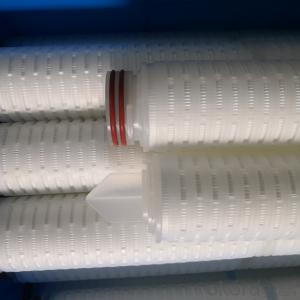

Pleated PTFE membrane filter cartridges for air or solvents

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydrophobic Pleated PTFE membrane filter cartridges for sterile air or solvents

PTFE Filter Cartridge

PTFE Filter isa sterilizing grade air & gas filter that utilize naturally hydrophobic

material provides effective retention of microbes and particles in air/gas.

Features

l Inherently hydrophobicity.

l High flow rates at low differential pressures.

l High steam cycle lifetimes and thermal strength.

l Reliable separation of microorganisms and bacteriophage.

Materials

l Media Layer: Hydrophobic PTFE

l Support Layer: Polypropylene

l End Caps/Core/Cage: Polypropylene

l O-Rings/Gaskets: Silicon, EPDM, Viton, Teflon

l Internal Adaptor Ring: PS / Stainless Steel 304

Operating Conditions

Max. running temperature | ≤80 ℃ |

Max. Allowable Differential Pressure | ≤5Bar(20℃) |

≤2Bar(80℃) | |

Inline Steaming Sterilize | 121 ℃, 30min@max differential Pressure of 0.05MPa up to 25 times |

Food and Biological Safety

Extractables | <30mg per 10 inch |

Endotoxins | <0.25EU/mL |

Ordering Information

PTFE | Micro Rating | Connection | Length | Gasket |

01=0.1μm | 0=222+Flat | 10=10 inch | S=Silicon | |

02=0.22μm | 5=222+Spear | 20=20 inch | E=EPDM | |

04=0.45μm | 7=226+Spear | 30=30 inch | V=Viton | |

10=1μm | F=DOE | 40=40 inch | F=PFA |

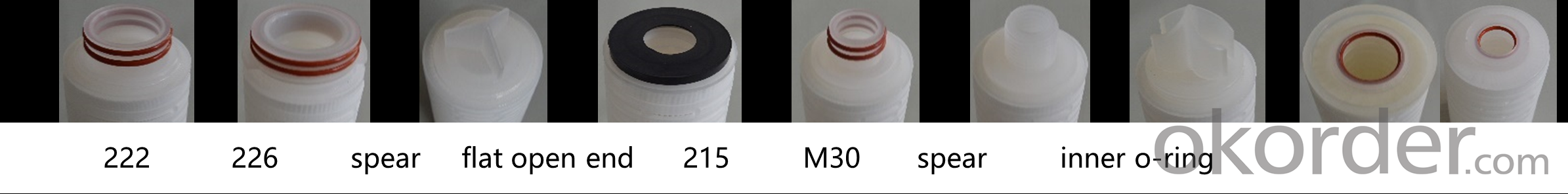

Connection details

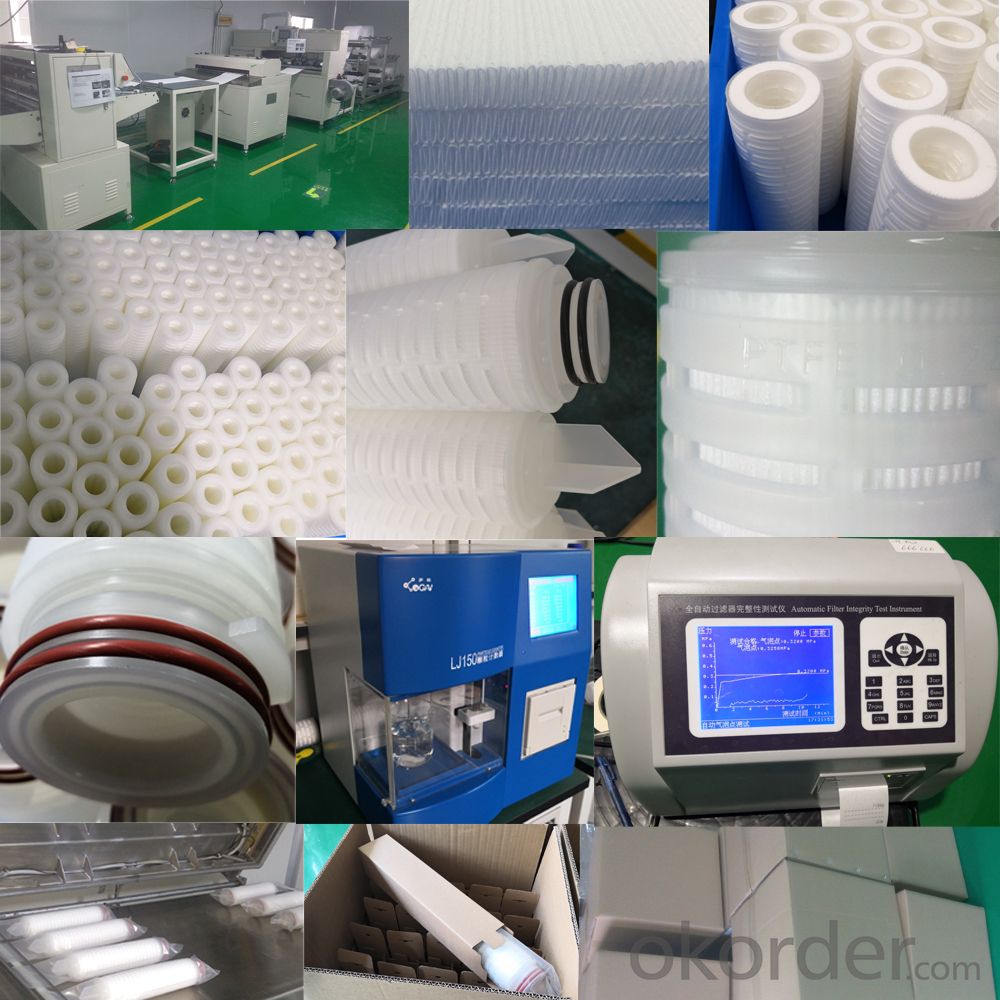

Process

- Q: Is the salt used for water purifier the industrial salt?

- the salt water is the regeneration of the ion, and the industrial salt is generally used.

- Q: What about the cooling performance of industrial refrigerators?

- expansion valve through small or blocked. The refrigerant will reduce the amount of liquid, the evaporation temperature of the air conditioner is low, and the evaporator fin will be frosted, and the refrigerant will not evaporate. It will continue to evaporate into the air return pipe and compressor. 4

- Q: Can industrial water filters be filtered by domestic water?

- PP filter cartridge: a variety of PP filter cartridge filter, the general price is low, but the filter is easy to plug, often need to change, and the filter accuracy is not high, only for the initial filtration of water.

- Q: What is the method of sludge treatment for industrial wastewater treatment equipment?

- With the development of energy, environment protection and chemical industry, the application field of ceramic filter is expanding, and the requirement of ceramic filter is higher and higher.

- Q: Do you have to drink alcohol for industrial power purification and filtration equipment?

- directly refused, and later will not let you go

- Q: What kind of filtration equipment do you use to treat wastewater?

- (1) the chemical precipitation method, and divided into neutralization precipitation and sulfide precipitation.

- Q: Principle of on-line self-cleaning filter for industrial water treatment and forced backwashing

- ) air scrubbing, backwashing, air cleaning, the purpose is to attach to the filter on the dirt stripping, strengthening backwash effect. Specific operation method is: after backwashing, close the water inlet valve, open the drainage to the bottom as a top, is 10 centimeters on the anthracite filter material, close the bottom row, open the blower and the air inlet valve, inlet control strength, specific criteria for the fancy mirror anthracite coal bed was suspended state moves up and down, can't let the filter violently up and down to avoid disorderly phenomeno

- Q: What is the difference between the filtered water from the household water purifier and the VAT water purchased?

- Another empty bucket and bucket replacement problems, the bottle and bottled water dispenser water base health and epidemic prevention, and bottled drinking water in the long time "is caused by a factor two pollution", the longer the more serious pollution, which is mainly the replacement of air and water cause, the pollutants in the air with the air into the barrel, because bottled drinking water can not inhibit the growth of bacteria, and soon the remaining water microorganisms exceed the standard, if the long-term consumption of contaminated drinking water, affect our health in.

- Q: How is the flow rate of an industrial automatic water filter calculated?

- The material and structure of the screen can greatly improve the flow area of the flow, effectively reduce the water resistance of the filter screen, and ensure the reliable operation. No jam, jam or plug occurs.

- Q: What are the categories of industrial water treatment equipment?

- precision filter, water tank self-cleaning sterilizer, ultraviolet water processor, efficient decontamination filter, hand brush filter, self cleaning brush RF filter, water filter, side stream processor, multifunctional electronic descaling device, constant pressure water supply unit, constant pressure water feeding unit,

Send your message to us

Pleated PTFE membrane filter cartridges for air or solvents

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches