Plastic Water Pipe Push Fittings for Butt Welded Flange Socket Flange Pipe Fittings in Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

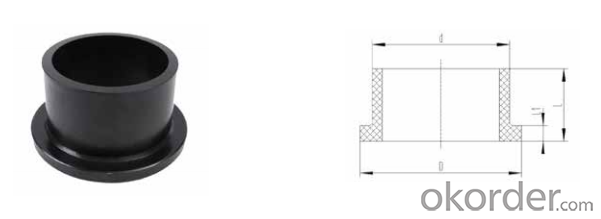

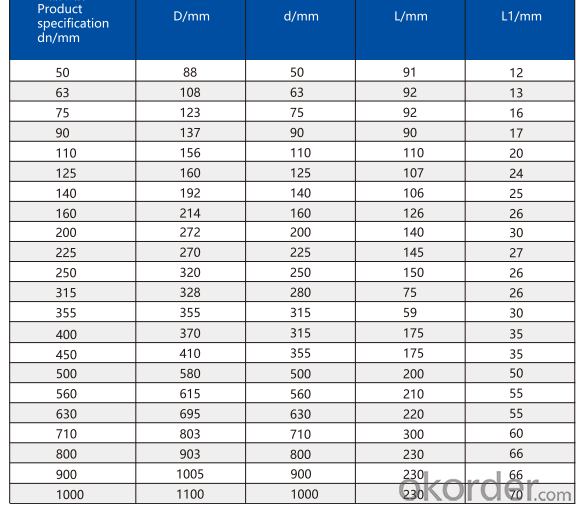

PE Butt Welded Flange Socket Flange

Pressure grade:

PN≤1.6MPa when DN<630MM

PN≤1.0MPa when DN≥630MM

Size: DN50MM-DN1000MM

Specification:

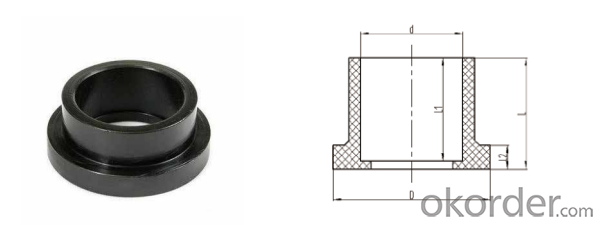

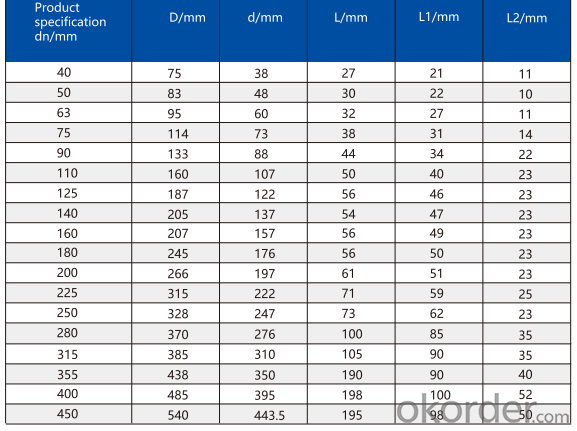

PE Socket Flange

Pressure grade:≤1.6MPa

Size: DN40MM-DN450MM

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Can plastic pipe fittings be used for water treatment systems?

- Yes, plastic pipe fittings can be used for water treatment systems. They are commonly used due to their corrosion resistance, durability, and ease of installation. However, it is important to ensure that the plastic material used is compatible with the specific water treatment chemicals and processes being employed.

- Q: Can plastic pipe fittings be used in fish farming systems?

- Yes, plastic pipe fittings can be used in fish farming systems. They are commonly used due to their durability, flexibility, and resistance to corrosion. Plastic fittings are easy to install, maintain, and can be customized to fit the specific needs of the fish farming system. Additionally, plastic fittings are non-toxic and do not leach harmful substances into the water, making them safe for the fish.

- Q: Can plastic pipe fittings be used in DIY projects?

- Yes, plastic pipe fittings can be used in DIY projects. They are commonly used for plumbing installations and repairs in homes or small-scale projects. Plastic fittings are lightweight, easy to install, and resistant to corrosion, making them a popular choice for DIY enthusiasts. However, it is essential to ensure compatibility with the specific type of pipe and to follow proper installation guidelines to ensure a secure and leak-free connection.

- Q: What are the different pressure ratings available for plastic pipe fittings?

- There are a variety of pressure ratings available for plastic pipe fittings, depending on the specific material and application. Some common pressure ratings include 80 psi, 100 psi, 150 psi, and 200 psi. The exact pressure rating needed will depend on factors such as the type of fluid being transported and the system requirements.

- Q: What are the connecting modes of steel wire mesh and plastic composite pipe?

- The tube surface melting and melt, melt pipe expansion and full clearance, until the appearance of pipe has two mutually melt, melt together, cooling after molding, pipe fittings are closely connected as a whole.

- Q: Can plastic pipe fittings be used for chemical injection systems?

- Yes, plastic pipe fittings can be used for chemical injection systems. Plastic materials such as PVC, CPVC, and polypropylene are commonly used for their chemical resistance and durability in handling various chemicals. However, it is important to select the appropriate type of plastic pipe fitting that is compatible with the specific chemical being injected to ensure safe and efficient operation of the system.

- Q: Can plastic pipe fittings be used for stormwater infiltration systems?

- Yes, plastic pipe fittings can be used for stormwater infiltration systems. Plastic pipe fittings offer several benefits such as durability, corrosion resistance, and ease of installation. They are commonly used in stormwater management systems to connect and direct the flow of water, including in infiltration systems where water is collected and infiltrated into the ground to recharge groundwater.

- Q: What are the common jointing methods for plastic pipe fittings?

- The common jointing methods for plastic pipe fittings include solvent welding, threaded connections, compression fittings, and push-fit or snap-fit connections.

- Q: How do you connect plastic pipe fittings to HDPE pipes?

- To connect plastic pipe fittings to HDPE pipes, you typically use a method called butt fusion. This involves heating the ends of both the fittings and the HDPE pipe until they reach a melting point. Once melted, the ends are pressed together and allowed to cool, creating a strong, leak-proof connection.

- Q: Can plastic pipe fittings be used for underground sprinkler systems?

- Yes, plastic pipe fittings can be used for underground sprinkler systems.

Send your message to us

Plastic Water Pipe Push Fittings for Butt Welded Flange Socket Flange Pipe Fittings in Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords