3/4" Plastic Water Pipe Fittings - Hot Melting Butt Welding Electrofusion Coupling Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

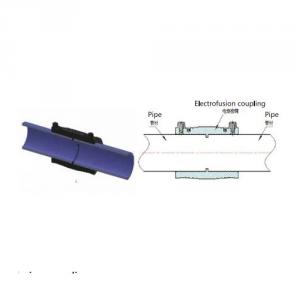

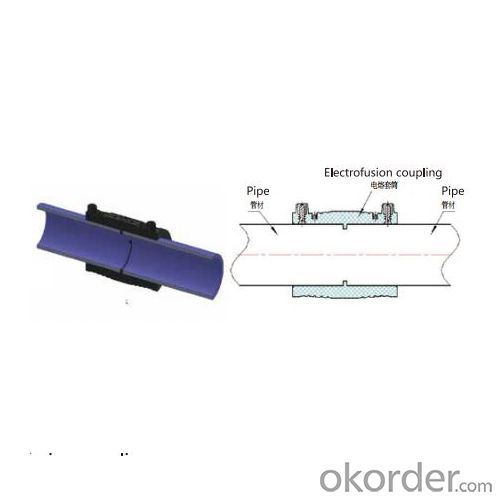

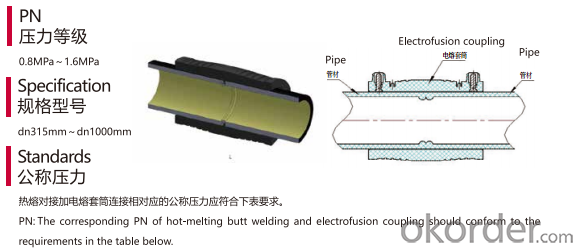

Hot Melting Butt Welding Electrofusion Coupling

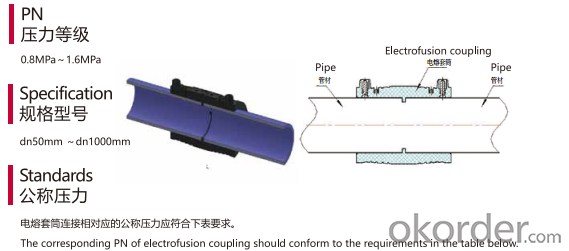

Pressure grade: 0.8MPa-1.6MPa

Size: DN50MM-DN1000MM

Specification

Pressure grade: 0.8MPa-1.6MPa

Size: DN315MM-DN1000MM

Specification

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Are plastic pipe fittings suitable for irrigation in greenhouse farming?

- Yes, plastic pipe fittings are suitable for irrigation in greenhouse farming. They are durable, resistant to corrosion, and have a longer lifespan compared to other materials. They are also easy to install and maintain, making them a popular choice for irrigation systems in greenhouse farming.

- Q: Can plastic pipe fittings be used for chemical processing systems?

- Plastic pipe fittings can be used for chemical processing systems, but it is important to choose the right type of plastic that is compatible with the chemicals being used. Certain plastics, such as PVC, CPVC, and PTFE, are commonly used in chemical processing due to their chemical resistance properties. However, it is crucial to consult with experts and consider the specific application requirements before selecting plastic pipe fittings for chemical processing systems.

- Q: Can plastic pipe fittings be used for irrigation filtration systems?

- Yes, plastic pipe fittings can be used for irrigation filtration systems. Plastic pipe fittings are commonly used in irrigation systems due to their durability, corrosion resistance, and affordability. They can easily be connected to various types of pipes and are compatible with different filtration components, making them suitable for the construction of irrigation filtration systems.

- Q: Are plastic pipe fittings resistant to high-temperature chemicals?

- Yes, plastic pipe fittings are generally resistant to high-temperature chemicals.

- Q: How do you choose the right size of plastic pipe fittings?

- To choose the right size of plastic pipe fittings, you need to consider the diameter of the pipe you are using. Measure the outside diameter of the pipe and select fittings that match this size. It is crucial to ensure a proper fit between the pipe and fittings to prevent leaks or disconnections. Additionally, referring to industry standards and consulting with professionals can also help in determining the correct size for your specific application.

- Q: When calculating the installation of water supply and drainage pipelines, are elbow and pipe fittings calculated separately?

- Water supply and drainage pipeline engineering, bends and fittings of the material shall be calculated separately, the installation fee is included in the pipeline installation quota, do not need to be calculated, such as industrial pipeline, the pipe installation fee plus

- Q: Are plastic pipe fittings suitable for potable water distribution networks?

- Yes, plastic pipe fittings are suitable for potable water distribution networks. They are widely used due to their durability, corrosion resistance, and affordability. Additionally, plastic pipe fittings are lightweight, easy to install, and do not require extensive maintenance.

- Q: Can plastic pipe fittings be used in fire extinguisher systems?

- No, plastic pipe fittings should not be used in fire extinguisher systems as they are not suitable for high-temperature environments and can potentially melt or fail under fire conditions. Metal fittings are recommended for these systems to ensure safety and reliability.

- Q: How do you prevent leaks in plastic pipe fittings?

- To prevent leaks in plastic pipe fittings, it is essential to follow a few key steps. Firstly, ensure that the pipe ends are clean and free from any dirt or debris. Next, use proper tools to tighten the fittings securely, avoiding over-tightening which may damage the threads. Applying a suitable sealant or thread tape to the male threads can also help create a watertight seal. Finally, regularly inspect the fittings for any signs of wear or damage, and promptly replace any faulty components to prevent leaks from occurring.

- Q: Can plastic pipe fittings be used for agricultural applications?

- Yes, plastic pipe fittings can be used for agricultural applications. Plastic fittings are commonly used in irrigation systems, providing durability, corrosion resistance, and ease of installation in various agricultural settings. They are suitable for transporting water, chemicals, and other fluids necessary for irrigation and crop cultivation.

Send your message to us

3/4" Plastic Water Pipe Fittings - Hot Melting Butt Welding Electrofusion Coupling Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords