Plastic Sheets - PVC Foam Board/Sheet Decorative High-Pressure Laminates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

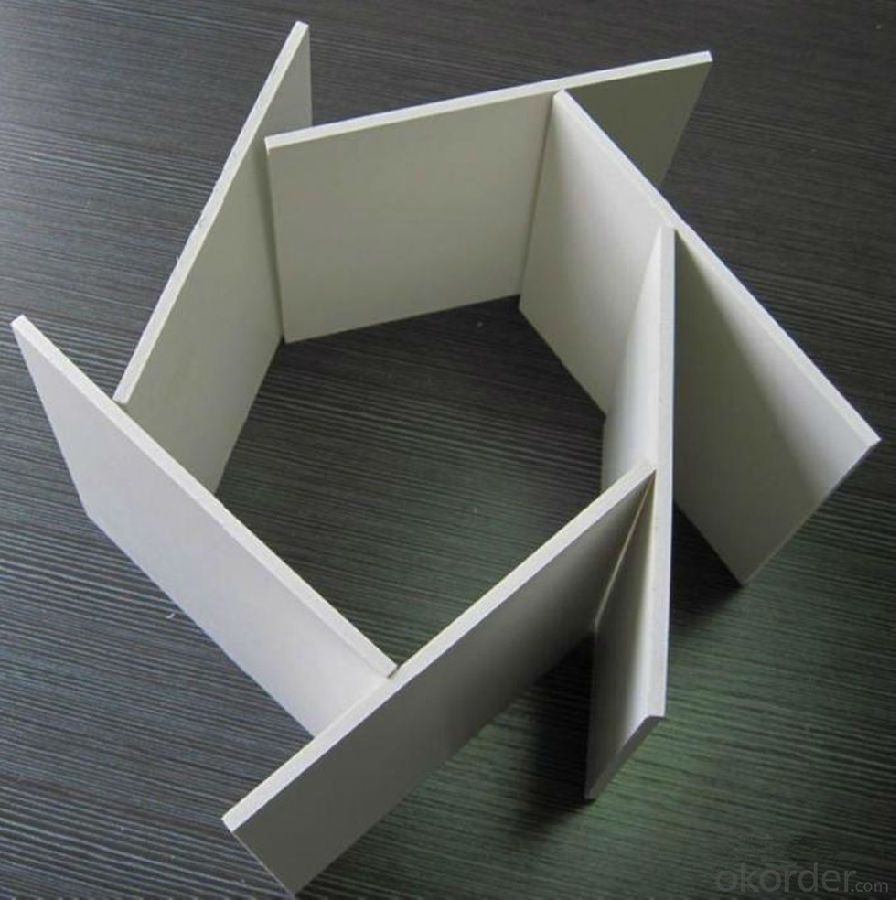

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

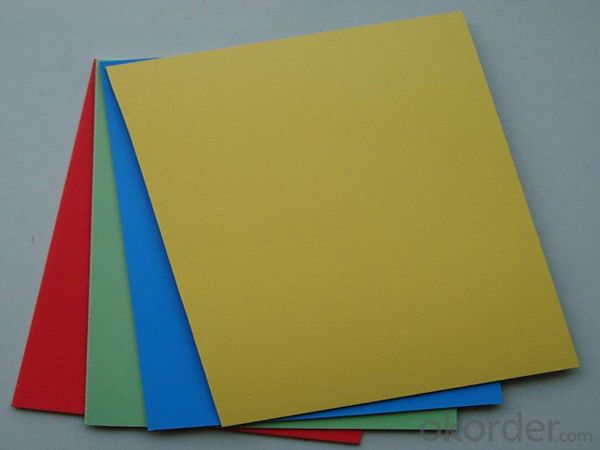

pvc celuka foam board, white pvc

foam board,black pvc foam board,colored pvc foam board,red pvc foam board,

yellow pvc foam board,green pvc foam board,blue pvc foam board and so on.

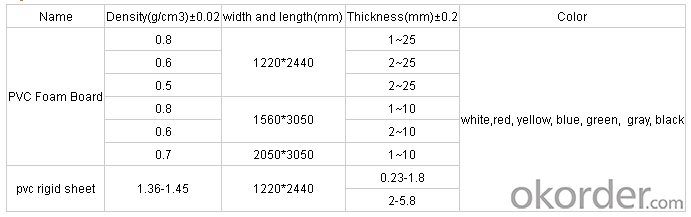

2. Product Specification

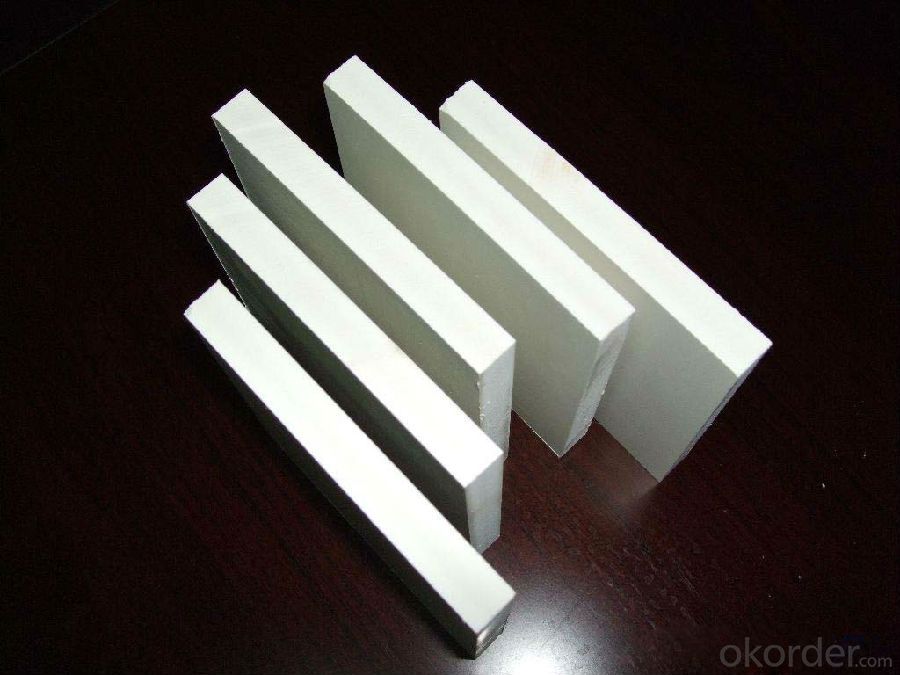

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

quantity(influence the delivery time and prices)

3. Product Features

1.Waterproof, fireproof retardant, moistureproof, anticorrosive, Weather resistant, moth-proofing, anti cracking, anti UV.

2.Less warping, stand wear and tear, acid and alkali resistance, easy coloring, no glue and paint

3.Can be nailed, drilled, shaved, chiseled, riveted, With wood properties and better than wood, color diversity

4. Safety and environmental protection, formaldehyde-free

5. Easy to install, easy to clean, easy to maintain

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

(4)Furniure Industry: TV Bench , Computer Table ,Kitchen and Bathroom Cabinets.

(5)Others :Interior Decoration for Vehicles,Trains,Yachts ,and Planes.

Application fields | The specific application |

Household furniture | tables , chairs , benches , stools – furniture, Sofa, Box spring, Bookshelf, clothing case, tea table, screen, frame, handle, plate, bar, newspaper rack. |

Construction | Mobile home, window frame, door plank, threshold, template, concrete stairs clap, wallboard, ceiling, floor, and various profiles, etc |

Industrials | Chemical corrosion barrack and public places, decorating plate, floor, channel, bench, and the casting model, the machine cover, pump shell, electrical materials, etc |

| ........ | |

5.More Details of Product

- Q: Is the extrusion plate the same as the foam board?

- Foam plastic plate: plastic foam or plastic sheet, or plastic sheet, foamed, washed or foamed

- Q: Can plastic sheets be used for bulletproof applications?

- Yes, plastic sheets can be used for bulletproof applications. Specially designed plastic materials, such as polycarbonate or polyethylene, can offer effective bullet resistance while being lightweight and flexible. These materials can be used to make bulletproof windows, shields, and body armor.

- Q: Can plastic sheets be used for skirting boards or baseboards?

- Yes, plastic sheets can be used for skirting boards or baseboards. Plastic skirting boards are a popular alternative to traditional wooden baseboards due to their durability, low maintenance, and moisture resistance. They are available in various colors and designs, providing a modern and sleek finish to a room.

- Q: hi everyone. making an outdoor sign for a school art/craft fair. have a plastic sheet with a nutcracker on it. want to adhere it to some plywood but dont want it to rip in the weather/ wind. i tried gorilla glue but it worked only so so. any good ideas are appreciatedthanks all

- Liquid nails It's what contractors use to adhere things like mirrors to walls. It comes in one of those large caulking tubes and you will need to use a caulking gun with it. (Bet you can borrow one from someone...) Ususally costs around $4 for a big tube of the generic brand of it. Available at wal-mart, home depot, etc. Spray glue won't work if what you are gluing has any weight to it - and it doesn't work well on porous surfaces like plywood. It's called Spray Bond, but don't waste your time and money on it.

- Q: I saw this on a solar panel website one time but am now unable to locate. It's a thin sheet of what appears to be plastic but it isn't clear... it's more opaque than anything. What the site claimed was that by shining the sun through this plastic (like shining the sun through a magnifying glass) you can intensify to some (great) degree onto a particular area. Anyone ever heard of it? Does this type of material exist? Is it a scam? Any information appreciate.

- sounds like a fresnel lense

- Q: Any cheap alternatives to the plastic stencil sheets?

- Masonite is too thick to work with. If you're doing street art, you still kind of want to be able to draw like you can with an exacto. Plastic sheeting is good if you want to be able to reuse a stencil. It also rolls up. But cheap poster board works just as well, except that it can fold, which you don't want. You can always go back and cut the plastic stencil from the poster. If you're dead set on the plastic, but can only find 8.5x11, just use clear scotch tape to match the edges. Just make sure the cut outs don't sever the whole seam. Poster board will tear, so let paint dry before you lay them down, and lift them off the painting surface before they dry

- Q: I like to play games now and then but my hands get sweaty when i play any game what makes at annoying to press buttons. (These have glossy finish which is basically gagging to be nice and slippery )is there an invisible stip of sticky plastic or something to put over the keys? any suggestion appreciated (:

- Gloves. going to look a litle silly, but itll do trick. no more sweaty keyboard, and saves you the hassle of looking for keyboard plastic protectors since you can buy gloves in your local department store.

- Q: Do plastic sheets have any impact on noise reduction?

- Yes, plastic sheets can have some impact on noise reduction. Depending on their thickness and density, they can help to block or absorb sound waves, reducing the amount of noise that passes through them. However, their effectiveness in noise reduction may be limited compared to other materials specifically designed for soundproofing purposes.

- Q: What are the thermal conductivity properties of plastic sheets?

- The thermal conductivity properties of plastic sheets vary depending on the type of plastic used. Generally, plastic sheets have low thermal conductivity, meaning they are poor conductors of heat. However, certain types of plastics, such as high-density polyethylene, can have relatively higher thermal conductivity compared to others.

- Q: Do I use 2x6? 2x4?. ????????

- First we sealed the walls with a cementicious sealer to assure no moisture to seep through the walls and it helps with dampness if the basement is below grade. Then we studded the walls out with 2x4 and attached them to the concrete floor with a Tap-Con gun which are used for shooting nails into concrete. We also allowed a small gap between the concrete wall and the frame for ventilation. Then we were ready for wiring and sheet rock. Good Luck.

Send your message to us

Plastic Sheets - PVC Foam Board/Sheet Decorative High-Pressure Laminates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords