Plastic Sheets - Heat Insulation High Density PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Specifications:

Specifications: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness: 1-33mm

Density:0.43-0.9g/cm3

Color: Mainly white, Black

2 .Product usage:

1mm-5mm Suitable for advertising materials, electronic instruments, packaging

15mm-20mm Suitable for furniture

10mm-20mm Suitable for bath cabinets

5mm-20mm Exhibition board, indoor and outdoor decorative panels (different customers have different requirements)

3mm Film Suitable for car interior ceiling

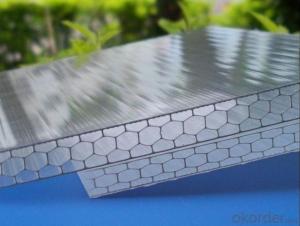

PVC foam board part of the end product icon:

3 .product features and advantages

A. The characteristics of waterproof, flame retardant, acid and alkali, mothproof, lightweight, heat insulation, sound insulation and damping.

B. and the same processing of wood, and processing performance is far superior to wood

C. is an ideal substitute for wood, aluminum and composite plates.

D. skin plate surface is very smooth, high hardness, not easy to have scratches, commonly used in the production of cabinets, furniture, etc.

4 .PVC foam board market prospect:

PVC foam has many advantages, the application of a very wide range, at present in developed countries has been a very wide range of applications, and the development of more slowly in china. With the country's energy saving and environmental protection requirements of building materials and other materials and the increasing scarcity of wood resources in China, PVC foam board will usher in rapid development.

5. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

6. FAQ:

(1)What is PVC board?

the implementation of GB/T4454-1996 quality, good chemical stability, corrosion resistance, high hardness, high strength, high strength, anti UV (aging), fireproof (self extinguishing), reliable insulation performance, smooth surface, no water, no deformation, easy processing etc.. This product is excellent heat molding material, can replace part of the corrosion resistance of stainless steel and other synthetic materials, and is widely used in petroleum, chemical industry, electroplating, water purification equipment, environmental protection equipment, and mining, medicine, electronics, communications and decoration industries.

(2)Main product specifications

Size: 1220*2440mm (about 70% of sales),

1560*3050mm (about 20% of sales),

2050*3050mm (about 10% of sales)

Main product thickness:1mm,2mm,3mm,5mm,8mm,10mm,12mm,15mm

Product details photo:

- Q: I have tried a variety of tapes that all slowly fall off over time. I'm looking for a more permanent way to attach two flat sheets of plastic about 10x10 together to form a seam.

- depending okorder

- Q: I have an idea for something I would like to make and sell. I would like to be able to stamp or cut a fairly simple shape out of flexible plastic sheets, a bit like margarine tub plastic. What machine/device/tool would I need to be able to cut or stamp this shape (and yes, I know scissors would work, but I would like to be able to make quite a few)

- A die cutter is one method. You can see simple versions at craft stores, it is like a cookie cutter with a sharpened edge. However, these cost a bit to have custom made, and they get dull. A CNC milling machine or Laser cutter could cut these out. A computer controlled engraving machine with the right bit could do this, too. The drawback is that it isn't incredibly fast, but you can change the shape at any time. CNC stands for Computer Numerical Control, what that means is that, like a Laser cutter you draw it on the computer. Then it uses a small spinning bit to cut out the plastic. Engraving machines are purpose-built CNC milling machines.

- Q: A plastic pin can hold two plastic plates together and can not leak

- I don't know how you install it. Is it another board attached to the sink? The utility model can be punched and punched on a water tank, bolt fixed, twisted with raw material tape, and the plate joint part is sealed with a O ring or a rubber cushion.

- Q: It is a duffle bag. The zipper is at the base (very bottom) of the bag. When I unzip it, there is a large, attached, piece of material. The material says UnderArmour and is attached to the bag.Is this for sitting on?

- it's to keep the shape of the bag ... so it's holds form not to sit on .. why would you bag come with a seat cushion?

- Q: hi everyone. making an outdoor sign for a school art/craft fair. have a plastic sheet with a nutcracker on it. want to adhere it to some plywood but dont want it to rip in the weather/ wind. i tried gorilla glue but it worked only so so. any good ideas are appreciatedthanks all

- Liquid nails It's what contractors use to adhere things like mirrors to walls. It comes in one of those large caulking tubes and you will need to use a caulking gun with it. (Bet you can borrow one from someone...) Ususally costs around $4 for a big tube of the generic brand of it. Available at wal-mart, home depot, etc. Spray glue won't work if what you are gluing has any weight to it - and it doesn't work well on porous surfaces like plywood. It's called Spray Bond, but don't waste your time and money on it.

- Q: Can plastic sheets be used for architectural applications?

- Yes, plastic sheets can be used for architectural applications. They are commonly used in construction for various purposes such as roofing, cladding, insulation, and glazing. Plastic sheets offer advantages such as durability, lightweight, flexibility, and cost-effectiveness, making them suitable for architectural projects.

- Q: Why is tarm paper or plastic sheeting put under hardwood floors?

- 1. Vapor barrier. 2. Cushion. 3.To allow the floor to move as it expands and contracts on drying/absorbing moisture. (You leave a gap at the edge don't you?)

- Q: What's the difference between memory plastic and sheet metal?

- TR 90 (plastic titanium) with memory materials with high current international popular ultra light frame material with high toughness and wear resistance and low coefficient of friction against energy transport frame fracture, prevent friction damage eyes and face made its specific structure anti resistance high temperature deformation resistant short between 350 degrees high temperature melt combustion residues release in line with European food grade material TR90 glasses surface lubrication density of 1.14-1.15 salt water than the floating plastic spectacle frame and plate frame about less light weight nylon 85% half bridge of the nose, ears for reducing burden youth use of anti-wear and anti aging, good solvent resistance, weather resistance, easy combustion, high temperature resistance and memory high resistance material deformation index 620kg/cm2 variant TR90 spectacles frame material elasticity, toughness and easy fracture strength fracture with operation safety and impact resistant nylon material: 2 times ISO180/IC:>125kg/m 2 elasticity to prevent eye damage caused by movement

- Q: What do you call the plastic sheets that x-ray s are embossed in?

- They are called negative plates.

- Q: Is the resin scraping board made of plastic?

- Resin usually refers to softening or melting range after heating. When softening, it tends to flow under external force. At normal temperature, it is solid, semi solid, and sometimes liquid organic polymer. Broadly speaking, any polymer compound that can be used as plastic material for processing raw materials is called resin.

Send your message to us

Plastic Sheets - Heat Insulation High Density PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords