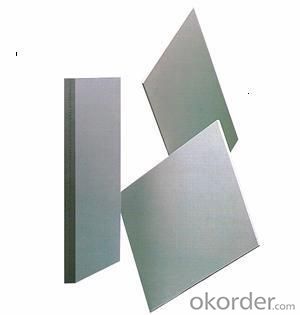

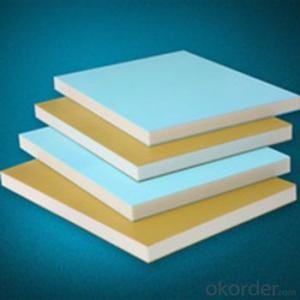

Plastic Sheets - 2024 High Quality PVC Sheet with Well Embossed

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Features

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed

Specifications:

1 width: 1220mm,

2 Length: 2440mm or as per your requirement,

3 Thickness: From 1mm to 30mm

4 Density: from 0.3 to 0.6

Parameter

| Products Name | pvc foam board machine |

| Thickness | 1~30mm thickness |

| Regular Size | 1220x2440mm (4’x8’) |

| Main Material | PVC powder |

| Surface Treatment | As per your request |

| Color | White |

| Certificate | SGS,3C,RoHs, ISO |

| Service | OEM |

| MOQ | 1*20GP |

| Payment | 30% deposit, 70% balance before shipment. T/T W/U M/G |

| Delivery Time | 7-30 days. |

| Packing | Carton box or wooden pallet packing. |

| production capability | 3000 tons per month |

FAQ:

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q3: Is free design assistance available for clients?

A3: If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.

Q4: What factors affect the price?

A4: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information to

get exact quotation.

- Q: a company is producing rectangular sheets of plastic. each has an area of (9x^2+30x+25) ft^2.. The dimensions of each sheet are of the form ax + b, where a and b are whole numbers. Find an expression for the perimeter of a sheet. Find the perimeter when x=4 ft.

- Let a = 3 Let b = 5 (3x + 5)? = (3x + 5)(3x + 5) (3x + 5)(3x + 5) = 9x? + 15x + 15x + 25 9x? + 15x + 15x + 25 = 9x? + 30x + 25 The perimeter (p(x)) is: p(x) = 4(3x + 5) p(4) = 4(12 + 5) p(4) = 48 + 20 p(4) = 68

- Q: What are the common applications of plastic sheets?

- Plastic sheets have a wide range of common applications, including packaging materials, construction materials, automotive components, signage, electrical insulation, greenhouse coverings, and various DIY projects.

- Q: About a metre square, by about 7mm thick.

- You would have to visit your local DIY/hardware or glass/window store to find out. Prices can vary area to area based on how much they have to pay the local wholesaler who sells to them. Acrylic is not cheap, it is expensive stuff. Good luck.

- Q: can you stitch cross stitching patterns on plastic canvas sheets?

- Yes, as long as the design uses only full stitches. 1/4 1/2 stitches will give you problems. Size is another issue, the smallest plastic canvas is 14 count. So you won't be able to do designs that are larger than the actual size of the sheet.

- Q: What are the temperature limits for plastic sheets?

- The temperature limits for plastic sheets can vary depending on the type of plastic. However, most plastic sheets have a temperature range of -20°C to 70°C (-4°F to 158°F) before they may start to deform or lose their structural integrity. It is important to consult the specific specifications or manufacturer guidelines for the plastic sheet in question to ensure proper usage within the recommended temperature limits.

- Q: What are the different surface treatments available for plastic sheets?

- There are several different surface treatments available for plastic sheets, including but not limited to: 1. Coating: A thin layer of material is applied to the surface of the plastic sheet to enhance its appearance, durability, or specific properties such as UV resistance, scratch resistance, or chemical resistance. 2. Printing: Various printing techniques can be used to apply designs, patterns, or logos onto the plastic sheet, including screen printing, digital printing, or pad printing. 3. Lamination: A layer of protective film or material is bonded to the surface of the plastic sheet to provide additional protection against scratches, abrasion, or chemicals. 4. Embossing: A pattern or texture is pressed into the surface of the plastic sheet to create a three-dimensional effect or improve grip. 5. Polishing: The surface of the plastic sheet is mechanically or chemically polished to enhance clarity, smoothness, and transparency. 6. Etching: A chemical or laser etching process is used to create designs, text, or patterns by removing or altering the surface of the plastic sheet. These surface treatments can be chosen based on the desired aesthetic, functional, or protective properties required for the specific application of the plastic sheet.

- Q: I had a pilonidal cyst removed from my natal cleft (aka butt crack) last Tuesday, and to reduce the risk of infection, the surgeon used surgical glue to close the wound's exterior, and a sheet of super-sticky surgical plastic to keep my cheeks together and provide another layer of protection from infection.Well, it started peeling up a bit at the top and bottom and letting some air get to the would, so I peeled off a little bit and trimmed it off (with help, lol). I went as far as I dared to, but I just hit a part where it hurt. I'm concerned about infection getting to the spots where air had already made it in, but I also don't want to open the wound.I don't have an appointment with my surgeon until Thursday- do you think it would be okay to wait for him to remove it, or should I just use some Vaseline to take the rest of it off now?

- Put some antibiotic ointment on it (neosporin etc). That will not only kill any bacteria that might be trying to get into the wound, but it will also loosen the stickiness of the tape, so that it comes off easily on its own without further injury. Put the ointment, then leave it alone until the doc sees it.

- Q: How much would it cost to replace a scratched plastic sheet floor in a kitchen? (approx 3x4 m2)?

- Not enough info to tell you. If you're doing the work yourself, go to a home store and price the sheet goods you want to replace it with. Read the installation directions to see what you have to do, and buy or rent the appropriate tools. Most home stores can give you plenty of advice on what you need to do. If you're not going to do the work, call some handymen and get some bids. Check their references and go with the one you like best.

- Q: Can plastic sheets be used for swimming pool covers?

- Yes, plastic sheets can be used as swimming pool covers. They are lightweight, affordable, and can effectively prevent debris from entering the pool. However, it is important to ensure that the plastic sheet is durable and UV-resistant to withstand outdoor conditions and provide proper insulation for the pool.

- Q: Can plastic sheets be used for greenhouse shading?

- Yes, plastic sheets can be used for greenhouse shading. Plastic sheets are commonly used as a cost-effective and easy-to-install option for providing shade in greenhouses. They can effectively reduce the amount of sunlight and heat entering the greenhouse, helping to maintain optimal growing conditions for plants. Additionally, plastic sheets are lightweight, durable, and available in different colors and thicknesses, allowing for customization based on specific shading needs.

Send your message to us

Plastic Sheets - 2024 High Quality PVC Sheet with Well Embossed

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords