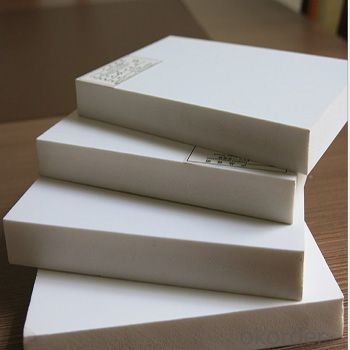

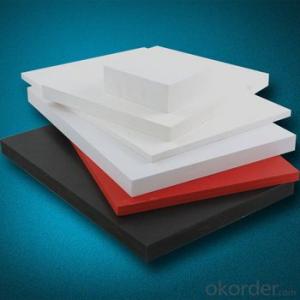

Plastic Sheets - 1mm - 20mm PVC Rigid Foam Board PVC Foam Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Specifications:

Specifications: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness: 1-33mm

Density:0.43-0.9g/cm3

Color: Mainly white, Black

2 .Product usage:

1mm-5mm Suitable for advertising materials, electronic instruments, packaging

15mm-20mm Suitable for furniture

10mm-20mm Suitable for bath cabinets

5mm-20mm Exhibition board, indoor and outdoor decorative panels (different customers have different requirements)

3mm Film Suitable for car interior ceiling

PVC foam board part of the end product icon:

3 .product features and advantages

A. The characteristics of waterproof, flame retardant, acid and alkali, mothproof, lightweight, heat insulation, sound insulation and damping.

B. and the same processing of wood, and processing performance is far superior to wood

C. is an ideal substitute for wood, aluminum and composite plates.

D. skin plate surface is very smooth, high hardness, not easy to have scratches, commonly used in the production of cabinets, furniture, etc.

4 .PVC foam board market prospect:

PVC foam has many advantages, the application of a very wide range, at present in developed countries has been a very wide range of applications, and the development of more slowly in china. With the country's energy saving and environmental protection requirements of building materials and other materials and the increasing scarcity of wood resources in China, PVC foam board will usher in rapid development.

5. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

6. FAQ:

(1)What is PVC board?

the implementation of GB/T4454-1996 quality, good chemical stability, corrosion resistance, high hardness, high strength, high strength, anti UV (aging), fireproof (self extinguishing), reliable insulation performance, smooth surface, no water, no deformation, easy processing etc.. This product is excellent heat molding material, can replace part of the corrosion resistance of stainless steel and other synthetic materials, and is widely used in petroleum, chemical industry, electroplating, water purification equipment, environmental protection equipment, and mining, medicine, electronics, communications and decoration industries.

(2)Main product specifications

Size: 1220*2440mm (about 70% of sales),

1560*3050mm (about 20% of sales),

2050*3050mm (about 10% of sales)

Main product thickness:1mm,2mm,3mm,5mm,8mm,10mm,12mm,15mm

- Q: I have a large sheet of plastic, or I think its plastic. Its about 1/8 inch thick, knubby on one side, smooth on the other and slightly pliable. I'd like to cut equal size panels to fit into my window shutters. I tried using a glass cutter and T square but that didn't work. Any suggestions?

- been a while since I last used a table saw --- but with the correct blade and a slow feed that is what is correct == you can probably rent a table saw if not owned -- try Lowe's or the HoDepot or a commercial tools rental store -- either way you will neew the correct blade [[ get set up and you can rent for one half day ]] ---- the thin plastic you are talking about is for a florescent light fixture [[ YES ? ]] and it is very brittle .. ir allowed to bind -- like against the table saw rip fence it will most likely splinter and crack in a way that you will not like ... mark your cut and cautiously free-hand the plastic with no rip=fence to avoid the bind ... and slide the smooth side across the T-saw ....a hand saw or a scoring w/knife is not recommended-------

- Q: How do plastic sheets compare to HDPE sheets?

- Plastic sheets are a broad category that encompasses various materials, including HDPE (High-Density Polyethylene) sheets. HDPE sheets, on the other hand, are a specific type of plastic sheet made from high-density polyethylene. In terms of comparison, HDPE sheets offer several advantages over other plastic sheets. They are highly durable, resistant to chemicals, UV rays, and moisture, making them suitable for outdoor applications. Additionally, HDPE sheets have excellent impact strength and are lightweight, making them easier to handle and install. However, it is important to note that not all plastic sheets are HDPE, and their properties and performance may vary depending on the specific material used.

- Q: Can some one please tell what is used as glue to fix plastic sheets ?

- buy an epoxy glue or a plastic steel glue. You can get them at walmarts or any autoparts store.

- Q: What is the average cost of plastic sheets?

- The average cost of plastic sheets depends on various factors such as the type of plastic, size, thickness, and quality. It can range from a few dollars for small, thin sheets to hundreds of dollars for larger, thicker sheets.

- Q: Some forums say it would be in Divisoria but I don't exactly know where it would be in that place. Any help would be greatly appreciated. Thanks.

- Buy Polypropylene

- Q: What types of plastics are used to make plastic sheets?

- There are various types of plastics used to make plastic sheets, including but not limited to polyethylene (PE), polypropylene (PP), polycarbonate (PC), polyvinyl chloride (PVC), and acrylic (PMMA).

- Q: What has happened and how can I get rid of this, along with preventing it?It's not something I can remove with scrubbing or water and it's not on the surface.

- The clouding is caused by multiple microfine scratches. These occur more often near the ends as these are the most exposed areas.

- Q: Can plastic sheets be recycled into new plastic products?

- Yes, plastic sheets can be recycled into new plastic products. Recycling facilities collect and process plastic sheets, breaking them down into small pieces or pellets. These pellets can then be melted and molded into new plastic products, reducing the need for virgin plastic materials and promoting sustainability.

- Q: that's all she wants me to bring over..should I worry ?

- Depends on where she wants to stick the bottle of tequilla after it's done!!!

- Q: Are plastic sheets resistant to warping from high temperatures?

- Yes, plastic sheets are generally resistant to warping from high temperatures. However, the exact level of resistance can vary depending on the type and quality of the plastic sheet.

Send your message to us

Plastic Sheets - 1mm - 20mm PVC Rigid Foam Board PVC Foam Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords