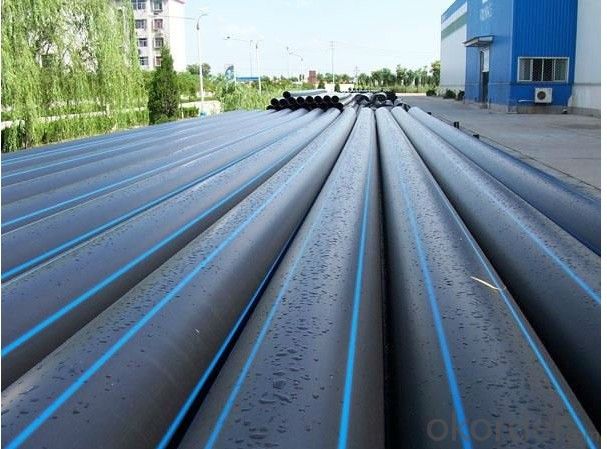

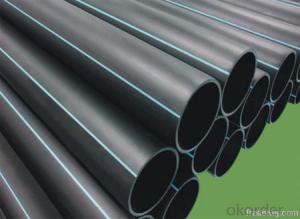

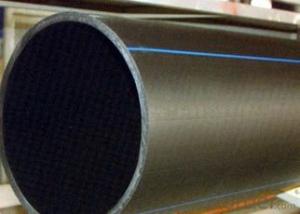

Plastic Pipe--HDPE Water Supply Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of HDPE Water Supply Pipe

Material: PE80/ PE100 (mainly PE 100 now).

Sizes: 20mm--630mm

SDR: SDR11,SDR13.6,SDR17,SDR21,SDR26,SDR33

Pressure: 0.4Mpa(PN4), 0.6Mpa(PN6), 0.8Mpa(PN8), 1.0Mpa(PN10), 1.25Mpa(PN12.5), 1.6Mpa(PN16)

Color: Black or others on request

Connection: Socket-fusion jointed, butt-fusion jointed , electron-fusion jointed, flange jointed

Standard: ISO4427, ISO4437, GB/T 13663-2000

Certification: ISO9001, ISO14001

Application: Water supply, Industries liquids transportation , sewage conduit

Identifies: black water pipe identifies the color at least three blue stripes, and evenly distributed along the pipe circumference

Advantage of HDPE Water Supply Pipe

1.Non-toxic, no heavy metal additives, no fouling, not breed bacterium,

2.Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums,

or electron chemical corrosion. except for few strong oxidants

3.High strength, good performance to resist the environmental stress cracking, good creep

resistance.

4.Good flexibility: small diameters PE pipe for water supply can be coiled and supplied for longer

length, which saves a large number of fittings , PE pipe can be easily shifted according to

requirement of the projects.

5.Light weight ,simple safe and reliable welding technique,convenient construction and lower cost

of the whole engineering,

6.Smooth interior wall, small water resistance, high flow capacity,

7.Long service life :up to 50 years under normal conditions.

8.Recyclable, benefit to the environment

- Q: How are steel pipes used in the construction of desalination plants?

- Steel pipes are used in the construction of desalination plants for various purposes such as transporting seawater, brine, and treated water, as well as for structural support in the plant's infrastructure. These pipes are durable, corrosion-resistant, and capable of withstanding high-pressure conditions, making them ideal for the harsh and corrosive environment of desalination plants.

- Q: How are steel pipes used in the power generation industry?

- Steel pipes are extensively used in the power generation industry for various purposes, such as transporting steam, water, and other fluids in power plants. They provide a reliable and durable solution for the high-pressure and high-temperature conditions found in power generation systems. Steel pipes are also used for the construction of boilers, condensers, and heat exchangers, ensuring efficient heat transfer and energy production. Additionally, steel pipes are employed in the exhaust system of power plants to safely and efficiently discharge emissions. Overall, steel pipes play a critical role in the power generation industry by facilitating the transportation of fluids and contributing to the reliable and efficient operation of power plants.

- Q: A333gr6 steel pipe and domestic material of the same?

- A333Gr.6 steel is no nickel steel is a kind of fine grain aluminum low temperature toughness of steel, therefore, also called Al killed steel. A333Gr.6 belongs to the United States ANSI and ASTM-SA333 cryogenic steel standards and is used at the lowest impact temperature of -46 degrees celsius. Its temperature, range of use and fracture toughness value are similar to those of domestic 16Mn steel (the minimum usage temperature of 16Mn steel is -40 degrees Celsius).

- Q: Is hot dipped plastic pipe steel?

- Hot dip pipe used in fluidized bed impregnation process, one-time into new anti-corrosion steel production process is the original film, plastic pipe or electrostatic nozzle replace (the products by physical treatment process)

- Q: How are steel pipes used in wastewater treatment plants?

- Steel pipes are used in wastewater treatment plants for various purposes such as transporting wastewater, carrying chemicals and additives, and supporting the infrastructure.

- Q: Can steel pipes be used for underground geothermal systems?

- Yes, steel pipes can be used for underground geothermal systems. Steel pipes are commonly used in geothermal applications due to their durability, strength, and resistance to corrosion. They can withstand high temperatures and pressures associated with geothermal systems, making them suitable for underground installations. Additionally, steel pipes are readily available and cost-effective, making them a popular choice in geothermal projects.

- Q: What are the factors affecting the durability of steel pipes?

- There are several factors that can affect the durability of steel pipes. These include corrosion, temperature fluctuations, mechanical stress, and exposure to chemicals or abrasive materials. Additionally, the quality of the steel used in the pipes, the design and construction of the piping system, and proper maintenance and inspection practices can also impact their durability.

- Q: Can steel pipes be recycled after their useful life?

- Yes, steel pipes can be recycled after their useful life. Steel is a highly recyclable material, and this includes steel pipes. Recycling steel pipes involves collecting the used pipes, cleaning them to remove any contaminants, and then processing them into new steel products. The recycling process helps to conserve natural resources, reduce energy consumption, and minimize waste. Additionally, recycling steel pipes helps to reduce the environmental impact associated with the production of new steel.

- Q: The plastic pipe and steel pipe difference

- The steel plastic pipe is a general term, which includes plastic pipe, plastic lined pipe. Plastic pipe external coating, zinc coated and so on in Shanghai, Fujian, Portland, professional in this area

- Q: How are steel pipes protected against internal scaling?

- Steel pipes are protected against internal scaling through various methods such as chemical treatments, use of corrosion inhibitors, and regular maintenance and cleaning procedures. These measures help to prevent the formation of scale, which can reduce the pipe's efficiency and lifespan.

Send your message to us

Plastic Pipe--HDPE Water Supply Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords