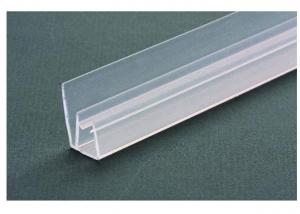

Auto Rubber Fittings Dustproof Cover Sheath

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Auto Rubber Fittings Dustproof Cover Sheath

Lead-time: 7-10days

ISO9001 & TS16949 factory

Qualified supplier of Panasonic/BYD

WSR's mold workshop Description of Auto Rubber Fittings Dustproof Cover Sheath

1. WSR have 12 CNC machines, 3EDM machines, we can make over 100sets rubber mould per month.

2. Compression/transfer/injection(both hot runner and cold runner are available) types.

3. The common mold steel we use are NAK80, P20, 4140, S50C

4. We have 15years experience in making rubber moulds, especially for rubber molds of electronic rubber parts, automotive rubber parts, toy tires, we are a leading rubber mould maker in China.

5. We have our own rubber products workshop, we can test the mold before ship the mold to customer.

6. We are currently making molds for Japan, Italy, UK, USA, Canada, South Asia companies.

7. Experience sales representative discuss with customer about the mold design prior to mold making.

8. Lead-time, prototype mold in 3-7days, production mold in 1-2weeks, complicated rubber molds like cold runner injection rubber molds in 30days.

Description of Auto Rubber Fittings Dustproof Cover Sheath

Material: comply to RoHS, silicone or rubber (NR, SBR, NBR, EPDM, CSM, CR, HNBR, VITON, AFLAS and more)

Hardness: 8 to 95 shore A, tolerance can be ±5 shore A, for some special products, we can reach ±3 shore A tolerance

Color: for rubber, usually black, for silicone, can be in any color as you want

Machine type: 50 to 400 tons

Molding service: we have our own mold workshop which have 12 sets CNC machines and provide compression/transfer/injection rubber molds

ISO9000 and TS16949 certificated factory

Mold/samples lead-time of Auto Rubber Fittings Dustproof Cover Sheath

For prototype mold, usually in 7days

For mass production mold, usually in 2 weeks

For some special molds, can be in 30days, especially for some automotive rubber molds

Small orders are welcomed

- Q: Where does the car use the most rubber parts?

- The most used rubber on the car must be the tires. The second is the rubber pad at the joint, as well as the rubber sleeve for the movable joint and the rubber seal for sealing. Apart from tires, the rest of the world is the most difficult to use because of the different models.

- Q: What impact does the rubber spray on the tires have on the car?

- Under normal circumstances is not affected. It will only cause bad looking. It is recommended to use tire special oil.

- Q: Silk ring mat, stainless steel pedal and rubber pedal, which is antiskid and wearable

- Use: can be used for wire ring mats, mats, mats, clipping suede leather mat, car mat, mats can improve the appearance of the driver's seat, enhance the foot at the foot of the strength and prolong the service life of anti-skid pads!

- Q: How do you maintain the rubber parts of the car?

- We all know that the application of Vaseline pan, is also very common, generally used for medical treatment, family and industry, but few people know that it is not a kind of hate excellent rubber softener. The rubber parts on the car are relatively large, and most of them are used to seal the windows and damping parts. On the one hand, they have the function of waterproof, and on the other hand, they have the function of vibration damping and buffering. With the vehicle to extend the use of time, these rubber parts will gradually aging hardening and even rupture, once the emergence of the phenomenon, it will cause bad sealing, not only can not wind and rain, reduce vehicle comfort, and maintenance of labor expense and high material cost.

- Q: Who can tell me what the inner structure of a car is like?

- The basic structure of a carAutomobiles are usually composed of four basic parts, the engine, the chassis, the body, and the electrical equipment.Automobile engine: the engine is the power device of the car. It is composed of engine block, crank connecting rod mechanism, valve train, cooling system, lubrication system, fuel system and ignition system (diesel engine without ignition system). According to the fuel engine, there are two kinds of gasoline and diesel engines; according to the way of operation, there are two kinds of two stroke and four stroke; the general engine is a four stroke engine.

- Q: What is the swelling glue used in automobiles?

- Expansion rubber is a kind of auto expansion adhesive tape and film made of synthetic rubber and resin as base material. It has excellent oil surface adhesion, operability, high expansion rate, filling property, elasticity and good adhesion.

- Q: How long does the car seal need replacing?

- When the window glass is damaged, the owner should check the sealing strip for damage. Since the window has been repaired, it often does not respond to the original shape. Therefore, in addition to ensuring that the window glass can be easily pulled or lifted, it is also necessary to pay attention to the tightness around the window glass. If the glass glazing rabbet slot uneven, rubber and glass, the glass tank is bad, the owner can easily seal off by hand.

- Q: What material is the rubber hose on the tank truck?

- Any of various steels that contain less than 2.11% of the mass of carbon but contain no alloying elements. Sometimes referred to as plain carbon steel or carbon steel.Carbon steel, also called carbon steel, refers to an iron carbon alloy with a carbon content of less than 2.11% Wc.Carbon steel, in addition to carbon, usually contains a small amount of silicon, manganese, sulfur and phosphorus.

- Q: Does the cushion cushion affect the vehicle?

- Its working principle is: it is installed on the spiral rubber shock absorber spring, when the car turns to shift the focus to the side causing the body tilt to the compression spring played a supporting role, so it can reduce the car roll. Is not to withstand the shock absorber spring over compression, it is not normal straight work but will make the spring more tough.

- Q: Can polyurethane rubber be used for automobile tires?

- Tolerable。 This technology is not yet available.

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | Domestic Market Rubber and Plastic Products 61.8 Northern Europe Rubber and Plastic Products 2.7 North America Rubber and Plastic Products 10 Oceania Rubber and Plastic Products 0.9 Eastern Asia Rubber and Plastic Products 5.6 Western Europe Rubber and Plastic Products 19 |

| Company Certifications | ISO 9001-2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Auto Rubber Fittings Dustproof Cover Sheath

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords