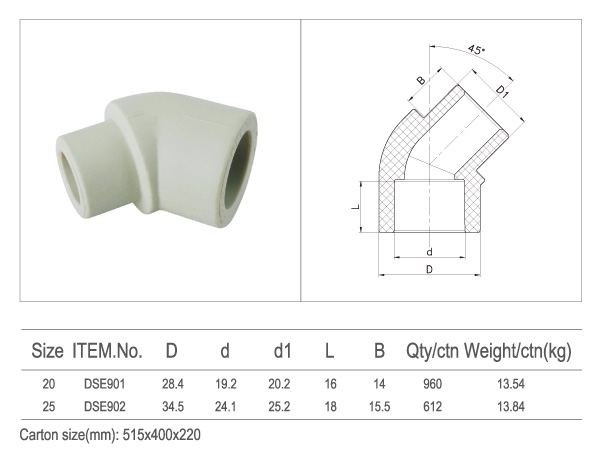

Plastic Compression PPR Elbow 45 Degree Internal/External Pipe Fitting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: PP-R

Technics: Forged

Type: Elbow

- Model Number: DSE901-902

- Connection: Welding

Shape: Equal

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20~25

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag + carton

Delivery Detail: 15 Days

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

- Q: Can plastic pipe fittings be used for stormwater drainage?

- Yes, plastic pipe fittings can be used for stormwater drainage. They are commonly used due to their durability, resistance to corrosion, and affordability. Plastic fittings also offer ease of installation and maintenance, making them a popular choice for stormwater drainage systems.

- Q: How do plastic pipe fittings compare to fiberglass fittings?

- Plastic pipe fittings are generally more affordable and readily available compared to fiberglass fittings. However, fiberglass fittings offer superior strength, durability, and resistance to corrosion and chemicals. They are also lightweight and have better thermal insulation properties. Ultimately, the choice between plastic and fiberglass fittings depends on the specific requirements and intended use of the fittings.

- Q: What are the main specifications and sizes of PVC pipe fittings?

- Because PVC is a hard plastic, to make it soft, a large amount of plasticizers must be added. Plasticizers are easy to release in a heated environment. If you are using DEHA, it will interfere with the human endocrine, cause women to breast cancer, birth defects, reduce the number of male sperm, or even mental disorders.

- Q: Are plastic pipe fittings resistant to UV radiation?

- Yes, plastic pipe fittings can be resistant to UV radiation. Many modern plastic pipe fittings are specifically designed and manufactured with UV stabilizers, which help to protect them from the damaging effects of UV radiation. These stabilizers prevent the plastic from degrading, becoming brittle, or losing its structural integrity when exposed to sunlight and other sources of UV radiation. However, it is important to note that not all plastic pipe fittings are UV resistant, so it is crucial to choose fittings that are specifically labeled or specified to have this property if UV exposure is a concern.

- Q: What are the different types of plastic pipe fittings?

- There are various types of plastic pipe fittings, including but not limited to, elbows, tees, couplings, unions, adapters, valves, and reducers. These fittings are used to connect and redirect pipes in plumbing and industrial applications.

- Q: Are plastic pipe fittings resistant to chemicals?

- Yes, plastic pipe fittings are generally resistant to chemicals. They are designed to withstand a wide range of chemicals and are commonly used in various industries where chemical resistance is required. However, the specific level of resistance can vary depending on the type of plastic used and the chemicals involved. It is important to consult the manufacturer or supplier for detailed information on chemical compatibility before using plastic pipe fittings in specific chemical applications.

- Q: Are plastic pipe fittings resistant to fire?

- No, plastic pipe fittings are not generally resistant to fire.

- Q: Can plastic pipe fittings be used for pharmaceutical manufacturing?

- No, plastic pipe fittings are not suitable for pharmaceutical manufacturing due to the risk of leaching chemical contaminants into the products.

- Q: Do plastic pipe fittings have a maximum operating pressure?

- Yes, plastic pipe fittings do have a maximum operating pressure. This maximum pressure limit is determined by the material and design of the fitting, and it is important to adhere to this limit to ensure the safety and integrity of the plumbing system.

- Q: Are plastic pipe fittings resistant to fungal growth?

- Yes, plastic pipe fittings are generally resistant to fungal growth due to their non-porous nature, which makes it difficult for fungi to thrive and grow on the surface. Additionally, most plastic pipe fittings are manufactured with antimicrobial properties that further inhibit the growth of fungi and other microorganisms.

Send your message to us

Plastic Compression PPR Elbow 45 Degree Internal/External Pipe Fitting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords