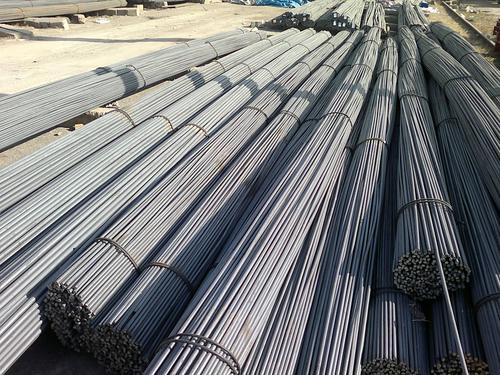

Plain Round Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Round Bar

1. Grade: GB, JIS, ASTM, EN

2. Grade: Q235, SS400, A36, S235JR

3. Diameter and mass: As below

Diameter | Mass | Diameter | Mass | Diameter | Mass |

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

6 | 0.22 | 22 | 2.98 | 53 | 17.30 |

7 | 0.30 | 24 | 3.55 | 56 | 19.30 |

8 | 0.40 | 25 | 3.85 | 60 | 22.20 |

9 | 0.50 | 26 | 4.17 | 63 | 24.50 |

10 | 0.62 | 28 | 4.83 | 65 | 26.00 |

11 | 0.75 | 30 | 5.55 | 70 | 30.20 |

12 | 0.89 | 32 | 6.31 | 75 | 34.70 |

13 | 1.04 | 34 | 7.13 | 80 | 39.50 |

14 | 1.21 | 36 | 7.99 | 85 | 44.50 |

15 | 1.39 | 38 | 8.90 | 90 | 49.90 |

16 | 1.58 | 40 | 9.86 | 95 | 55.60 |

17 | 1.78 | 42 | 10.90 | 100 | 61.70 |

18 | 2.00 | 45 | 12.50 | 120 | 88.85 |

19 | 2.23 | 48 | 14.20 | 140 | 120.93 |

20 | 2.47 | 50 | 15.40 | 150 | 138.82 |

4. Material: Mild Steel

5. Heat treatment of high quality steel:

Fire: Isothermal annealing temperature is 800 ~ 880 °C, with 10 ~ 20 °C, the furnace cooling to about 600 °C, hardness above HB269.

Preheat temperature: 730-730 °C

Quenching temperature: 1190-1210 °C

Tempering temperature: 540-595 °C

Cold drawn, hardness 285 HBS

Cold drawn after annealing condition, hardness 277 HBS

Quenching methods: oil quenching, air cooling or salt bath quenching

Usage and Applications of High Quality Round Bar

1) Suitable for making various strong cutting tool abrasion resistance, impact resistance.

2) Used to produce all kinds of high hard and super hard saw blade, drill, tap, broach, gear hob and various kinds of milling cutter.

3) Used for advanced punching die, screw die, and the toughness and complicated shape of the punch, etc.

4) Is used for cold forging die and drawing mode, etc.

5) Recommended watchcase factory, screw factory and other cold stamping products industry use.

Packaging & Delivery of High Quality Round Bar

Packaging Detail: All goods are packed in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: 45 days

Trade terms: FOB, CFR, CIF

MOQ: 25 tons per specification; we can negotiate the quantity if the specification is normal or we have stock of one specification.

Weight: The price invoicing on theoretical weight basis or actual weight basis depends on customer’s request.

Shipment: The shipment of bulk break or container is depends on customer’s request and the situation of the port of destination.

Documents given: Full set of original clean on board bill of lading; Original signed commercial invoice; Original packing list; Policy of insurance; Certificate of origin and what the target market needs.

Production Flow of High Quality Round Bar

The common processes are preheated forging quenching, dual refinement solution process, cooling quenching and isothermal quenching. We use heat treatment for dual refinement solution process. The main measures process is high temperature solution and refinement cycle. High temperature solution can improve the carbide morphology and particle size. The aim is to make the loop refinement ultrafine austenite grains.

- Q: Can steel round bars be used in the agricultural industry?

- Yes, steel round bars can be used in the agricultural industry. They are often used for constructing support structures such as fences, gates, and livestock pens. Steel round bars are also used in machinery and equipment manufacturing for applications like tractor attachments, irrigation systems, and grain storage bins. Their strength, durability, and versatility make them suitable for various agricultural purposes.

- Q: Can steel round bars be painted?

- Steel round bars can indeed be painted in order to protect them from corrosion and improve their appearance. However, prior to painting, it is crucial to properly prepare the surface of the steel round bars by thoroughly cleaning, degreasing, and eliminating any rust or mill scale. This can be accomplished through various methods such as sandblasting, wire brushing, or chemical cleaning. Once the surface is adequately prepared, it is necessary to apply a primer specifically formulated for steel to enhance the adhesion of the paint. Subsequently, the desired paint can be applied to the steel round bars using brushes, rollers, or spray equipment. It is essential to select a paint that is suitable for outdoor use and offers ample protection against harsh weather conditions. To ensure the long-lasting durability of the painted steel round bars, regular maintenance and periodic repainting may be necessary.

- Q: Can steel round bars be used for making agricultural equipment or machinery?

- Agricultural equipment and machinery can indeed be made using steel round bars. Steel, a material known for its versatility and durability, is commonly employed in the manufacturing of various agricultural equipment and machinery. Steel round bars, specifically, are frequently utilized for the creation of essential components like shafts, axles, and rods, which are vital for the proper functioning of agricultural machinery. These round bars offer strength, stability, and resistance to wear and tear, making them well-suited for the demanding tasks within the agricultural industry. Moreover, steel is highly resistant to corrosion, a particularly crucial characteristic in agriculture where equipment is exposed to harsh environmental conditions. Overall, steel round bars are a dependable option for constructing agricultural equipment or machinery due to their mechanical properties and ability to endure the challenging conditions of agricultural operations.

- Q: Can steel round bars be used in the production of industrial machinery?

- Yes, steel round bars can be used in the production of industrial machinery. Steel round bars are commonly used in the manufacturing of machine components such as shafts, axles, gears, and fasteners due to their high strength, durability, and versatility. They provide excellent structural support and can withstand heavy loads and stress, making them ideal for use in various industrial machinery applications.

- Q: Can steel round bars be used in the production of forgings?

- Yes, steel round bars can be used in the production of forgings. Steel round bars are commonly used as raw materials for forging processes. The round bars are heated to a specific temperature and then shaped using various forging techniques such as hammering, pressing, or rolling. The heat and pressure applied during the forging process help to enhance the mechanical properties of the steel, making it stronger and more durable. Steel round bars are ideal for producing forgings as they provide a consistent and uniform shape, ensuring the final product meets the required specifications. Additionally, steel round bars offer versatility in terms of size, grade, and composition, allowing for a wide range of applications in various industries such as automotive, aerospace, and construction.

- Q: Can steel round bars be used in the production of construction equipment?

- Yes, steel round bars can be used in the production of construction equipment. Steel round bars are commonly used in the construction industry due to their strength, durability, and versatility. They can be used to manufacture various components of construction equipment such as axles, shafts, gears, and structural supports. The high tensile strength of steel round bars ensures that the equipment can withstand heavy loads and harsh operating conditions. Additionally, the machinability and weldability of steel round bars make them suitable for fabrication processes involved in the production of construction equipment. Overall, steel round bars are a reliable and commonly used material in the construction industry for manufacturing construction equipment.

- Q: How is the weight of a steel round bar calculated?

- The weight of a steel round bar is calculated using the formula: weight = volume × density. The volume of a round bar is determined by multiplying the cross-sectional area (πr^2) with the length of the bar. The density of steel is usually known, so by plugging in these values, we can calculate the weight of the steel round bar.

- Q: What are the different types of steel round bars used in the marine industry?

- There are several types of steel round bars commonly used in the marine industry, including stainless steel round bars, carbon steel round bars, and alloy steel round bars. Stainless steel round bars are highly corrosion-resistant and are often used in applications where exposure to saltwater is common. Carbon steel round bars are strong and durable, making them suitable for various marine components and structures. Alloy steel round bars offer enhanced strength and toughness, making them ideal for demanding marine applications that require high performance and resistance to wear and tear.

- Q: What are the advantages of using nickel-copper alloy steel round bars?

- Nickel-copper alloy steel round bars offer several advantages. Firstly, their resistance to corrosion and oxidation is excellent, making them ideal for use in harsh environments like the marine or chemical industries. This ensures the longevity and durability of the bars, reducing the need for frequent replacements. Secondly, these round bars have outstanding mechanical properties. The addition of nickel and copper enhances their strength, toughness, and hardness, making them suitable for heavy-duty applications in construction, manufacturing, and engineering. They can withstand heavy loads and resist deformation or breakage, contributing to the overall safety and reliability of the structures or components they are used in. Another advantage is their excellent thermal stability. The alloy has a low coefficient of thermal expansion, allowing it to withstand high temperatures without significant dimensional changes. This is particularly important in applications involving extreme heat, such as in the aerospace or power generation industries. The thermal stability of the bars ensures their dimensional integrity, reducing the risk of warping or cracking under high-temperature conditions. Furthermore, Nickel-copper alloy steel round bars offer good electrical conductivity. This is beneficial in applications that require the transmission of electric current, such as electrical wiring or power distribution systems. The high electrical conductivity of the alloy ensures efficient and reliable electrical connections, minimizing power loss and maximizing performance. In conclusion, the advantages of nickel-copper alloy steel round bars include excellent corrosion resistance, superior mechanical properties, thermal stability, and good electrical conductivity. These characteristics make them suitable for a wide range of applications in various industries, providing durability, strength, and reliability.

- Q: What are the different types of steel round bar alloys for improved strength?

- There are several types of steel round bar alloys that provide improved strength, including carbon steel, alloy steel, stainless steel, and tool steel. Each of these alloys has different properties and compositions, making them suitable for various applications where enhanced strength is required.

Send your message to us

Plain Round Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords