Pipe Crimpling Connection Crimping Steel Sleeve with Flange with Clamp

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

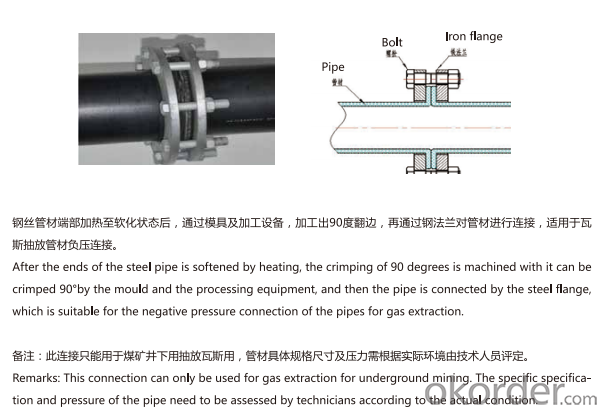

Pipe Crimpling Connection

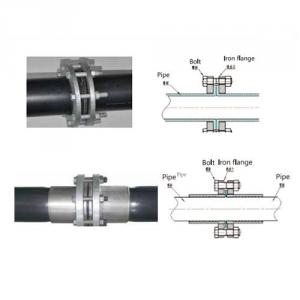

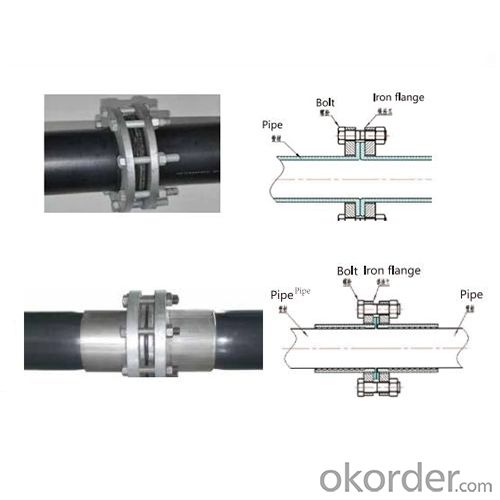

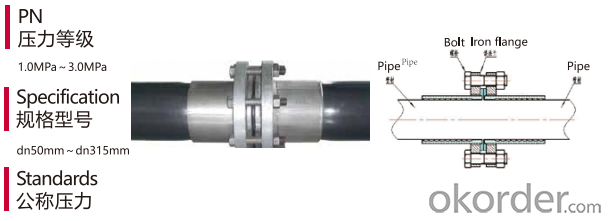

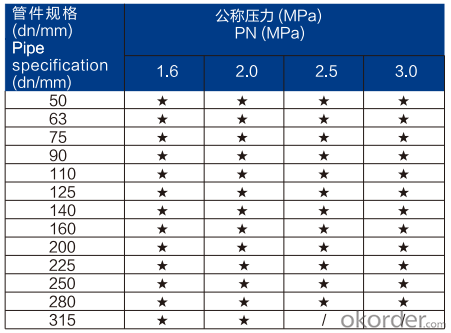

Crimping Steel Sleeve with Flange

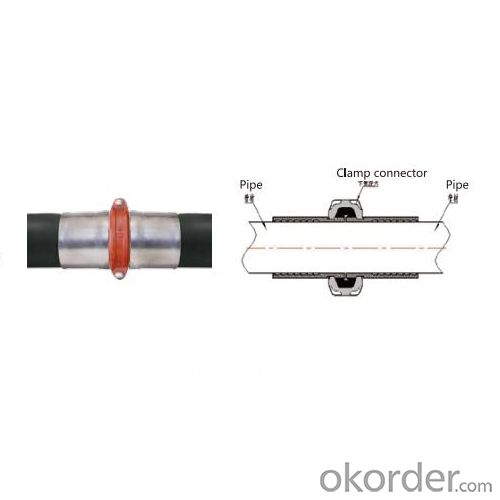

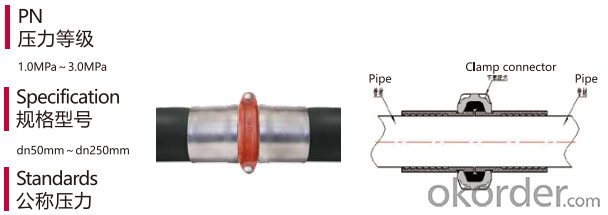

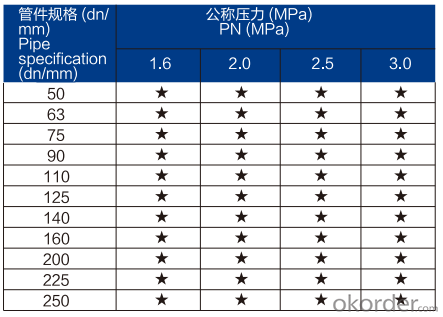

Crimping Steel Sleeve with Clamp

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Can plastic pipe fittings be used for hydrogen gas storage?

- No, plastic pipe fittings cannot be used for hydrogen gas storage. Hydrogen gas is highly reactive and can cause degradation and embrittlement of plastic materials, leading to potential leaks and safety hazards. It is recommended to use materials like metal alloys or composite materials specifically designed for hydrogen gas storage.

- Q: Can plastic pipe fittings be used for ductwork installations?

- No, plastic pipe fittings are typically not suitable for ductwork installations. Ductwork requires materials that are specifically designed to handle the air flow and pressure requirements, along with being fire-resistant. Plastic pipe fittings may not meet these necessary criteria and could pose a safety risk if used for ductwork installations.

- Q: How do you connect plastic pipe fittings to pipes?

- To connect plastic pipe fittings to pipes, you typically need to follow these steps: 1. Cut the plastic pipes to the desired length using a pipe cutter or saw. 2. Use sandpaper or a deburring tool to remove any burrs or rough edges from the cut ends of the pipes. 3. Apply a primer or cleaner to both the pipe ends and the inside of the fitting to ensure proper adhesion. 4. Apply a solvent-based cement or glue to the primed surfaces. 5. Insert the pipe into the fitting, twisting it slightly to ensure a tight fit. 6. Hold the pipe and fitting together for a few seconds to allow the cement to set. 7. Wipe away any excess cement using a clean cloth or rag. 8. Allow the cement to cure as per the manufacturer's instructions before applying pressure or using the system.

- Q: What are plastic pipe fittings?

- Plastic pipe fittings are connectors used to join or connect sections of plastic pipes together. These fittings are designed to create a secure and leak-proof connection, allowing for the efficient flow of liquids or gases through the piping system. They come in various shapes, sizes, and types to accommodate different pipe sizes and applications.

- Q: Can plastic pipe fittings be used for both hot and cold water supply?

- Yes, plastic pipe fittings can be used for both hot and cold water supply.

- Q: Indoor plastic water supply pipe, 20 of the 20 refers to the inside diameter or outside diameter?

- The composite pipe is typical of aluminum plastic tube, but it has been phased out because of its thermal expansion and cold contractionPlastic pipe is the most commonly used PPR water pipe, safe, non-toxic, convenient installation, low prices and many other reasons, making it the most commonly used water pipes in home improvement. But because of environmental hormones, more and more people began to use metal tubes or PPR lined metal pipes as water supply pipelines.

- Q: How do plastic pipe fittings work?

- Plastic pipe fittings work by connecting sections of plastic pipes together in a leak-proof manner. They are designed with various shapes, sizes, and connections to accommodate different pipe systems. These fittings usually have threads, sockets, or grooves that allow them to be securely attached to the pipe ends. The fittings create a tight seal using compression, glue, or heat fusion methods, ensuring that the pipes remain connected and prevent any leakage.

- Q: Can plastic pipe fittings be used in storm drain systems?

- Yes, plastic pipe fittings can be used in storm drain systems. They are commonly used due to their durability, corrosion resistance, and affordability. Plastic fittings are available in various sizes and configurations, making them suitable for different storm drain system requirements.

- Q: What are the different connection methods for plastic pipe fittings?

- There are several different connection methods for plastic pipe fittings, including solvent welding, compression fittings, push-to-connect fittings, and threaded connections.

- Q: Do plastic pipe fittings have a maximum operating flow rate?

- Yes, plastic pipe fittings typically have a maximum operating flow rate. This rate is determined by the design and material of the fitting, as well as the pressure and temperature conditions it will be subjected to. It is important to consult the manufacturer's specifications and guidelines to ensure that the flow rate does not exceed the recommended limits for the specific fitting being used.

Send your message to us

Pipe Crimpling Connection Crimping Steel Sleeve with Flange with Clamp

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords