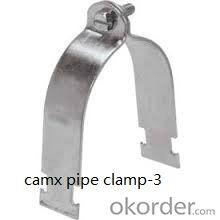

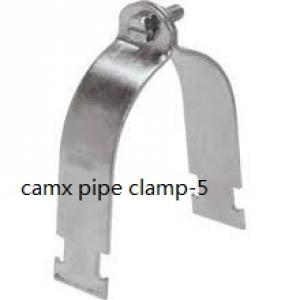

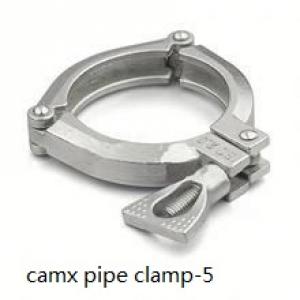

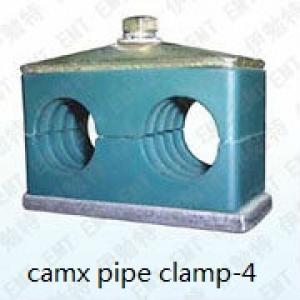

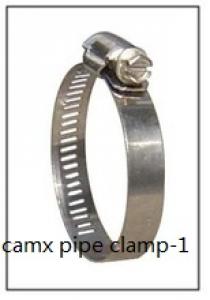

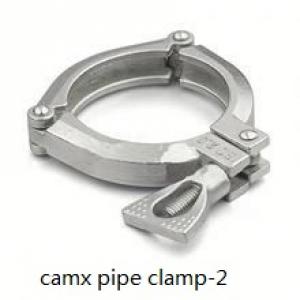

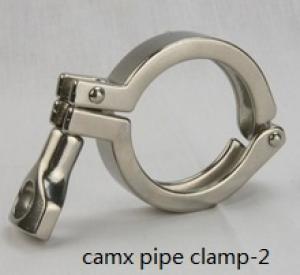

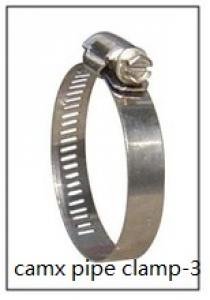

stainless steel pipe clamp with rubber

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Usage: Pipe Clamp

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

Material: steel、matel;Galvanized iron ,stainles

Band width:3mm/20mm

Connection:welding

Model number:As your requirement

Structure:Swivel clamp

Certificate:ISO9001:2008

Feature:

1.Use the open internal and external circle structure,and with screw fixed.It is effectively to solve the problem that when small diameter solft tube connect the hared tube,it is easy appear dead angle,and liquid or gas leakage problem.Easy structure,Easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn't to worry fracture and other problems

Surface: zinc plated Packaging

4.Accord with DIN3017 Standard.By 48 hours salt and fog test,it has a good corrosion resistance

5.By our last 48 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Working Temp: -40 ℃ ~ 110 ℃

Size:3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2

Structure: Suspension Clamp and so on On-time shipment and pre-shipment product quality safeguards clamp is mainly used in automobiles,tractors, ships, gasoline engine, and so on each kind of mechanical

device for oil, gas, hydraulic hose connector, various types of

rubber tube interface must join parts fastening.

Detail: plywood case ,pallets or any other package as buyer's requirements

Delivery Detail: about 20-30days

- Q: How does three-phase motor check current?

- Fu photoelectron FM 7 series high precision digital multimeter professional measuring instruments, portable, large screen LCD digital display and backlight, easy reading, single hand operation for measuring range switch, with overload protection and low battery indicator, is an ideal tool for the use of professional maintenance personnel, factories, schools and other institutions the.

- Q: Can the 5 (20) A meter withstand the current of 30A?

- 5 (20) A stands for this meter, allowing long running currents not exceeding 20A, instead of representing 20A for a short period of time. As for the meaning of that 5, nor is it representative of the rated current, but should be called the reference current. It is a benchmark used in the inspection and test of electric meters, such as detecting the light load of electric meters. The full load。 Starting current. And so on, that's the percentage of this 5A. For example, when the current reaches 1% of 5A, it can measure accurately, and achieve the standard of accuracy, such as measuring the accuracy of the meter under the ratio of 1%, 10%, 50%, 70%, 100%, etc. of 5A. As a reference, this parameter is meaningless to the user.

- Q: Is the flow meter good or the multimeter?

- The multimeter is also called the multiplex table, the multimeter, the three meter, the multiplication table and so on. It is an indispensable measuring instrument in the electric power and electronic departments. It is mainly used to measure the voltage, current and resistance.

- Q: Methods use a table clamp type table and the matters needing attention

- Clamp current meter high, low two, for without dismantling the current in the circuit fault line under the condition of direct measurement. The following methods: (1) the use of high voltage clamp meter should be paid attention to when the voltage clamp current meter, prohibit the use of low voltage electric current clamp meter high voltage measurement circuit. With high voltage clamp meter measurement, by the two person operation, non duty measurement should fill in second working ticket, should wear gloves when measuring stand on the insulating mat, must not touch the other equipment, to prevent a short circuit or grounding.

- Q: Clamp meter cable direction? Why do I change the direction of measurement with a cable, the current is not the same

- There is no direction in the clamp table and the card line. This is what you said

- Q: How to measure the actual current of three-phase induction motor?

- Clamp meter is composed of a current transformer and current meter assembly. The iron core of the current transformer can be opened when the wrench is tightened; the wire through which the current is measured can be cut through the opening of the iron core without cutting off, and when the wrench is released, the iron core is closed. Through the test circuit of the core, the wire becomes the primary coil of the current transformer, in which the current is induced in the two coil through the current.

- Q: Is there a caliper meter that can measure direct current?

- Magnetic balance type current sensor called compensation sensor, namely the primary current Ip generated in the magnetic core premises through a secondary magnetic field coil current magnetic field generated by the compensation, the compensation current of Is accurately reflect the current of primary side Ip, so that the Holzer device is in the working state of zero magnetic flux detection.

- Q: The power consumption of the same load, different power motors?

- The key lies in the size of the load, according to the current data you provide, basically can determine whether the motor is loaded; if the motor using 37kW, because the load torque constant, the motor for rated torque, it is necessary to reduce speed, increasing the current, the current may be not reached before 70A would have burned the motor.

- Q: Excuse me, great God. What is a DC clamp type?

- Through the test circuit of the core, the wire becomes the primary coil of the current transformer, in which the current is induced in the two coil through the current. A current meter connected with the two coil is then instructed to measure the current of the line being measured.

- Q: Generator carbon brush fire how to deal with?

- Generator is DC or AC, DC generator carbon brush ignition, then the coil is short circuit, to find a short separation, just fine! AC generator carbon brush ignition, then the carbon brush is not good to change it, there may be carbon brush in front of the copper ring is too dirty, with sandpaper sand just fine.

Send your message to us

stainless steel pipe clamp with rubber

- Loading Port:

- Qingdao

- Payment Terms:

- TT LC

- Min Order Qty:

- 100 pcs pc

- Supply Capability:

- 300000pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords