Aluminum Strips Lowes for Petrochemical Industries with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

*The high export tax of aluminum ingot, the coil has better price than ingot.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

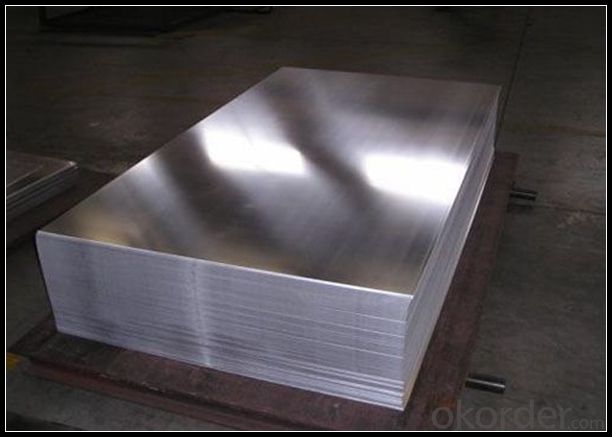

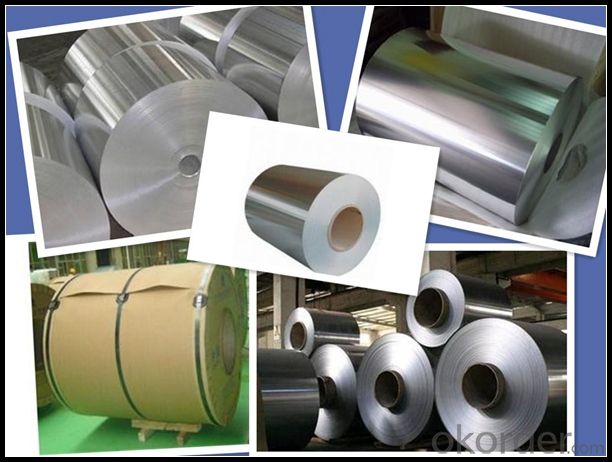

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Is it possible to use aluminum strips for the purpose of covering the interior walls of a building?

- <p>Yes, aluminum strips can be used for interior wall cladding. They are known for their durability, low maintenance, and resistance to moisture and corrosion, making them suitable for various interior applications. Aluminum strips are lightweight, easy to install, and can be used in both residential and commercial settings. They come in various finishes and colors, allowing for customization to match the desired aesthetic. However, it's important to ensure proper installation and adherence to building codes and safety standards.</p>

- Q: This question asks for the steps to attach aluminum strips to a wall or roof surface.

- <p>To install aluminum strips on a wall or roof, first measure and mark the area where you want to install the strips. Ensure the surface is clean and dry. Apply a suitable adhesive or use screws, depending on the type of strip and surface. Align the first strip and press firmly or secure with screws. For subsequent strips, use a spacer if needed to maintain consistent spacing. Check alignment regularly and ensure all strips are level. Seal any gaps with appropriate sealant and finish with a protective coating if required. Always follow the manufacturer's instructions for the specific product you are using.</p>

- Q: Can aluminum strips be recycled repeatedly without any loss in quality?

- <p>Yes, aluminum strips can be recycled indefinitely without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the metal's properties. In fact, recycled aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. This makes aluminum recycling an environmentally friendly and sustainable practice.</p>

- Q: Is it possible to utilize aluminum strips as materials for constructing roofs?

- <p>Yes, aluminum strips can be used for roofing materials. They are known for their durability, resistance to corrosion, and lightweight properties. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is often used in modern architecture for its sleek look and low maintenance requirements. However, it's important to ensure that the aluminum strips are properly installed and meet building codes for safety and effectiveness.</p>

- Q: Does aluminum corrode in a manner similar to rusting?

- <p>Aluminum does not rust in the same way as iron or steel. Instead, aluminum reacts with oxygen in the air to form a thin, protective layer of aluminum oxide on its surface. This oxide layer prevents further corrosion, unlike rust which can compromise the integrity of iron and steel. While aluminum can tarnish or become discolored due to exposure to certain elements or chemicals, it does not rust in the traditional sense.</p>

- Q: What kind of mask is good for welding aluminum strips?

- However, the overall quality of the active carbon mask is not high, carbon content, filtration efficiency is not up to standard. You can choose some professional brands to produce some products, to avoid these problems.

- Q: This question asks for a comparison of the pros and cons of using aluminum strips as a material for exterior cladding on buildings.

- <p>Aluminum strips for exterior cladding offer several advantages, including their lightweight nature, which reduces structural load. They are also resistant to corrosion, making them suitable for various climates and weather conditions. The ease of installation and maintenance is another benefit, as aluminum is less prone to damage and requires minimal upkeep. Additionally, aluminum strips can be easily recycled, contributing to sustainability efforts. However, there are disadvantages such as the potential for thermal expansion, which can lead to buckling or distortion over time. Aluminum may also dent or scratch more easily than some other materials, and it can conduct heat and cold, potentially leading to energy inefficiency. Lastly, while it is cost-effective in the long run, the initial installation cost can be higher compared to some traditional materials.</p>

- Q: Is it possible to utilize aluminum strips in environments with high temperatures?

- <p>Aluminum strips can be used in high-temperature environments, but their performance and longevity depend on the specific conditions and the alloy type. Pure aluminum has a melting point of 660掳C (1220掳F), but aluminum alloys can be designed to withstand higher temperatures. For instance, some aluminum alloys are used in aerospace and automotive applications where they experience high temperatures. However, prolonged exposure to high temperatures can lead to material degradation, so it's crucial to select the right alloy and consider the temperature limits specified by the manufacturer for the intended application.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a wall.

- <p>To install aluminum strips on a wall, first measure and mark the area where you want to install the strips. Clean the wall surface thoroughly to ensure proper adhesion. Apply a strong adhesive or use wall anchors and screws, depending on the weight and size of the strips. Align the first strip at the bottom and press firmly to secure it. Use a level to ensure it's straight. Attach subsequent strips side by side, maintaining a consistent gap if desired. Smooth out any bubbles or wrinkles with a putty knife. Once all strips are installed, allow the adhesive to cure according to the manufacturer's instructions before handling.</p>

- Q: This question asks for examples of uses for aluminum siding that are not commonly thought of.

- <p>Aluminum siding is traditionally associated with residential and commercial building exteriors due to its durability and low maintenance. However, its versatility extends to less common applications such as: 1) Marine applications, where it's used for boat hulls and docks due to its resistance to corrosion from saltwater. 2) Agricultural structures, like barns and silos, for protection against weather and pests. 3) In the automotive industry for car body panels and truck beds, providing lightweight and impact-resistant surfaces. 4) For creating custom art pieces and sculptures, as aluminum can be easily shaped and finished. 5) In the manufacturing of temporary structures like disaster relief shelters, offering quick assembly and durability. These uses showcase the adaptability of aluminum siding beyond its typical applications.</p>

Send your message to us

Aluminum Strips Lowes for Petrochemical Industries with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords