Paddle Laminating Roller-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

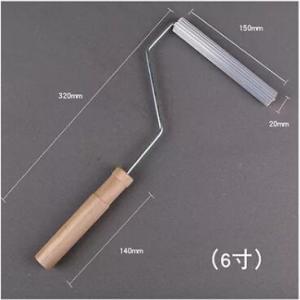

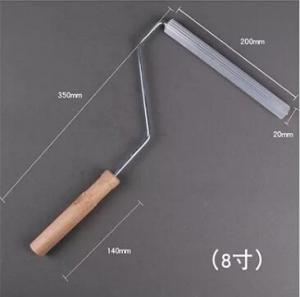

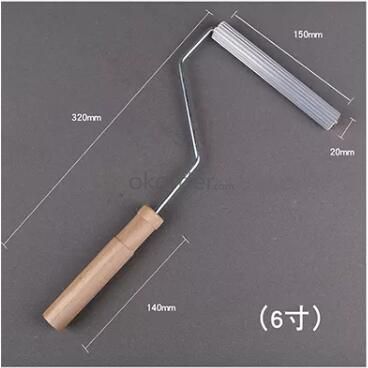

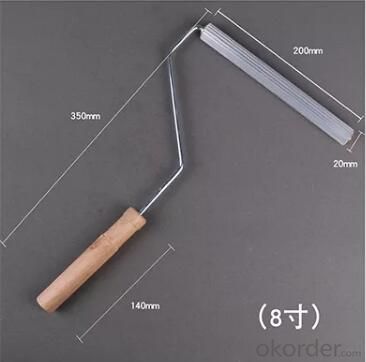

Paddle Laminating Roller

Product Description

Paddle Laminating Roller is widely used in the production of glass fiber reinforced plastic, and the inner surface of the bubble roller puncture, for removing air bubbles from lamination, leveling and compaction of resin coating to drive bubbles.

Technique Data

Type: | Roller Brush |

Handle: | Wooden and plastic |

Brush Material: | Aluminum |

Feature | Non-slip handle, multi-size, good material, high quality, durable |

Use | Remove air bubbles |

Color | Customized |

Size | 2‘’3‘’4‘’5‘’6‘’8‘’ |

MOQ | 100pcs |

Delivery Detail | About 15-20 days after having received the deposits. |

- Q: Is fiberglass chopped strand compatible with silicone resin?

- Yes, fiberglass chopped strand is generally compatible with silicone resin. Silicone resins are known for their excellent adhesion properties and can bond well with various materials, including fiberglass. The compatibility between the two depends on factors such as the specific type and formulation of the silicone resin, as well as the surface treatment of the fiberglass. It is recommended to conduct compatibility tests or consult the manufacturer's guidelines to ensure proper adhesion and performance when using fiberglass chopped strand with silicone resin.

- Q: Is fiberglass chopped strand suitable for sports equipment manufacturing?

- Yes, fiberglass chopped strand is suitable for sports equipment manufacturing. It provides excellent strength, durability, and lightweight properties, making it ideal for producing sports equipment such as hockey sticks, bicycles, and tennis rackets. The fiberglass reinforcement enhances the performance and longevity of the sports equipment, making it a popular choice in the industry.

- Q: Can fiberglass chopped strand be used in pipe manufacturing?

- Yes, fiberglass chopped strand can be used in pipe manufacturing. Fiberglass chopped strand is a versatile material that can be used in various applications, including pipe manufacturing. It offers several advantages such as high strength, corrosion resistance, and lightweight properties. The chopped strands can be mixed with resin and formed into a pipe shape using various manufacturing processes such as filament winding or pultrusion. The resulting fiberglass pipe exhibits excellent mechanical properties, including high tensile strength and stiffness, as well as resistance to chemicals and extreme temperatures. Additionally, fiberglass pipes are known for their longevity and low maintenance requirements, making them a popular choice in industries such as oil and gas, chemical processing, and wastewater treatment.

- Q: Is fiberglass chopped strand resistant to extreme weather conditions?

- Yes, fiberglass chopped strand is generally resistant to extreme weather conditions. It has excellent resistance to both high and low temperatures, as well as UV radiation, making it suitable for outdoor applications that are exposed to harsh weather conditions.

- Q: Is fiberglass chopped strand compatible with different coating methods?

- Yes, fiberglass chopped strand is compatible with different coating methods. Fiberglass chopped strand is commonly used as a reinforcement material in various coating processes, including but not limited to resin infusion, pultrusion, hand lay-up, and spray-up. The chopped strands are typically mixed with a liquid resin to form a composite material, which can then be applied to a surface using the desired coating method. The compatibility of fiberglass chopped strand with different coating methods allows for its versatile use in various industries such as automotive, construction, aerospace, and marine.

- Q: What are the safety precautions for handling fiberglass chopped strand?

- When handling fiberglass chopped strand, there are several safety precautions that should be followed to ensure the well-being of individuals. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and a dust mask. This will help protect the skin, eyes, and respiratory system from potential irritants or allergens that may be present in the fiberglass material. Additionally, it is crucial to work in a well-ventilated area or use a local exhaust ventilation system to minimize exposure to airborne particles. Fiberglass chopped strand can release fine fibers or dust particles when handled, which can be harmful if inhaled or come into contact with the skin. To further reduce the risk of skin irritation or injury, it is advisable to wear long-sleeved shirts and pants, as well as closed-toe shoes. This will provide an extra layer of protection against any potential contact with the fiberglass material. When working with fiberglass chopped strand, it is recommended to handle it gently and avoid creating excessive dust or fibers. This can be achieved by using proper handling techniques, such as minimizing agitation or shaking of the material. Lastly, it is crucial to maintain good hygiene practices. After handling fiberglass chopped strand, individuals should thoroughly wash their hands and any exposed areas of the body with soap and water. This will help remove any potential fibers or dust particles that may have come into contact with the skin. By following these safety precautions, individuals can minimize the risks associated with handling fiberglass chopped strand and ensure their personal safety. It is also important to consult the manufacturer's guidelines and any applicable safety data sheets for specific handling instructions and precautions.

- Q: Can fiberglass chopped strand be used in construction applications?

- Yes, fiberglass chopped strand can be used in construction applications. It is commonly used in the manufacturing of various construction materials such as insulation, roofing, pipes, and panels. The chopped strands are mixed with resins and binders to create strong and durable composite materials that are lightweight, corrosion-resistant, and have excellent thermal and sound insulation properties.

- Q: Is fiberglass chopped strand suitable for aerospace interior components?

- Yes, fiberglass chopped strand can be suitable for aerospace interior components. It is lightweight, strong, and has excellent fire resistance properties, making it a preferred choice for various interior applications in the aerospace industry. Additionally, it offers good insulation and corrosion resistance, making it a reliable material for aerospace interior components.

- Q: Can fiberglass chopped strand be used in the production of electrical insulators?

- Fiberglass chopped strand is indeed applicable in the manufacturing of electrical insulators. This versatile material boasts exceptional electrical insulation properties. With its high dielectric strength, it effectively opposes the flow of electrical current and prevents any leakage. Furthermore, fiberglass exhibits resistance against moisture and chemicals, rendering it suitable for a wide range of electrical applications. In the production of electrical insulators, fiberglass chopped strand is typically combined with a resin matrix to form a composite material that provides insulation and mechanical strength. This composite can be molded into various shapes and sizes to cater to the specific requirements of electrical insulators utilized in diverse applications. All in all, fiberglass chopped strand proves to be a dependable and cost-efficient option for the production of electrical insulators.

- Q: How is the thermal stability of fiberglass chopped strand composites determined?

- The thermal stability of fiberglass chopped strand composites is typically determined through various tests and analysis methods. These may include thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), and thermal mechanical analysis (TMA). These tests measure factors such as weight loss, heat flow, and dimensional changes at different temperature ranges, helping to establish the composite's resistance to high temperatures and its ability to retain its structural integrity under thermal stress.

Send your message to us

Paddle Laminating Roller-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords