1 1/2 Inch PE Injection Elbow Welded Elbow Plastic Pipe Fittings for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

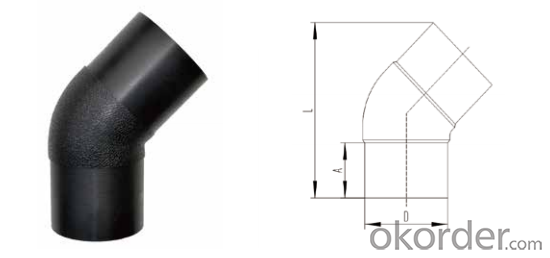

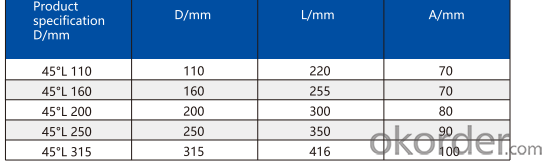

45° PE Injection Elbow

Pressure grade: ≤1.6MPa

Size: DN110MM-DN315MM

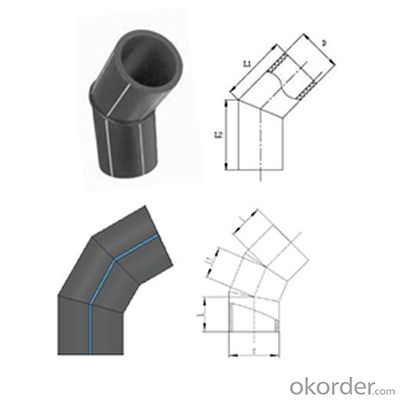

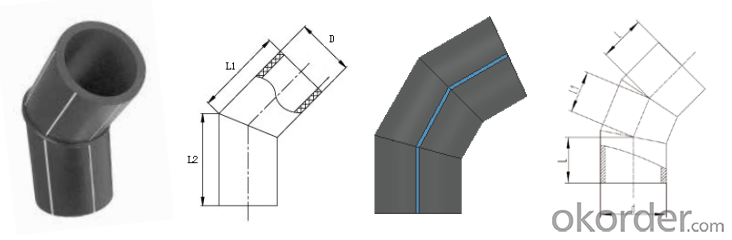

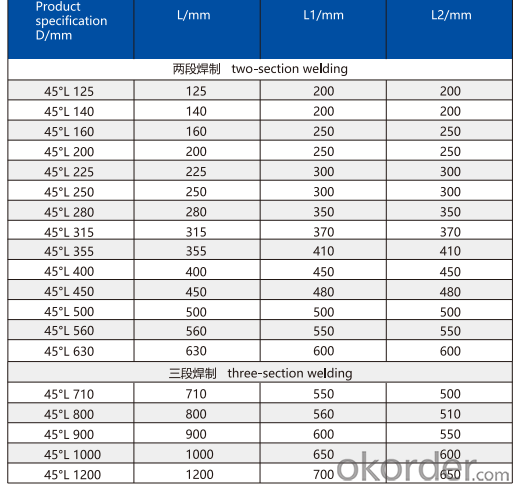

45° PE Welded Elbow

Pressure grade: ≤1.25MPa

Size: DN12MM-DN1200MM

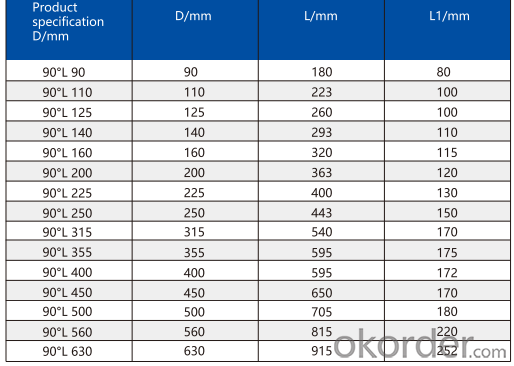

90° PE Injection Elbow

Pressure grade:

PN≤1.6MPa when DN<400MM

PN≤1.0MPa when DN≥400MM

Size: DN90MM-DN630MM

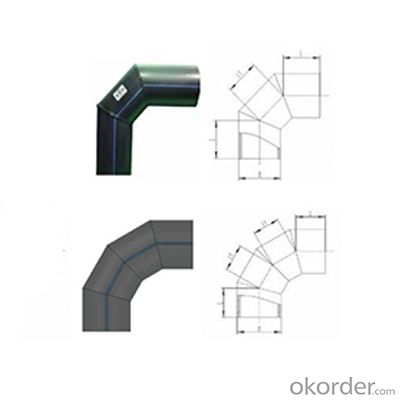

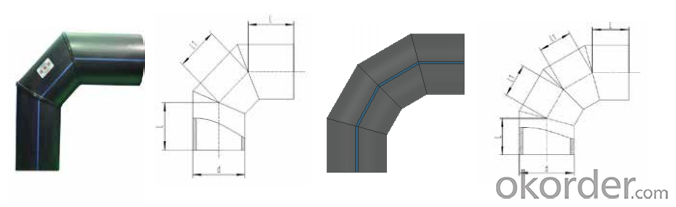

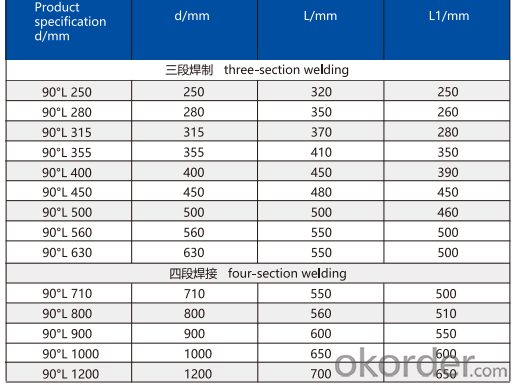

90° Welded Elbow

Pressure grade: ≤1.25MPa

Size: DN250MM-DN1200MM

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Can plastic pipe fittings be used for cooling water in power plants?

- Yes, plastic pipe fittings can be used for cooling water in power plants. Plastic pipes and fittings are commonly used in water distribution systems as they are resistant to corrosion, lightweight, and have a long service life. However, the specific choice of materials and fittings will depend on the temperature, pressure, and other requirements of the cooling water system in the power plant.

- Q: Are plastic pipe fittings resistant to water hammer?

- Yes, plastic pipe fittings are generally resistant to water hammer. Due to their flexibility and ability to absorb pressure spikes, plastic fittings can help minimize the impact of water hammer in plumbing systems. However, it is important to choose fittings that are specifically designed to handle water hammer and follow proper installation guidelines to ensure optimal performance.

- Q: Are plastic pipe fittings resistant to UV discoloration?

- Yes, plastic pipe fittings are generally resistant to UV discoloration. Many plastic materials used in pipe fittings are specifically designed to withstand exposure to sunlight and UV rays without discoloring or degrading. However, it's important to note that the level of UV resistance can vary depending on the specific type of plastic used. It is recommended to check the manufacturer's specifications for UV resistance before selecting plastic pipe fittings for outdoor applications.

- Q: How long do plastic pipe fittings typically last?

- Plastic pipe fittings typically have a lifespan of around 50 to 100 years, depending on factors such as the type of plastic used, quality of installation, and exposure to environmental conditions.

- Q: Can plastic pipe fittings be used for CO2 capture systems?

- Yes, plastic pipe fittings can be used for CO2 capture systems. Plastic pipes and fittings are commonly used in various industrial applications, including CO2 capture systems. They offer advantages such as corrosion resistance, ease of installation, and cost-effectiveness. However, it is important to ensure that the plastic material chosen is compatible with CO2 and can withstand the relevant pressure and temperature conditions in the system.

- Q: Can plastic pipe fittings be used in fire hose reel systems?

- No, plastic pipe fittings should not be used in fire hose reel systems. It is important to use fittings made of materials that are specifically designed and approved for fire safety, such as brass or stainless steel. These materials have the necessary durability and resistance to high pressure and heat that are crucial in fire-fighting situations.

- Q: Can plastic pipe fittings be used for cooling water systems?

- Yes, plastic pipe fittings can be used for cooling water systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and ability to handle high flow rates. Additionally, plastic fittings are lightweight and easy to install, making them a cost-effective choice for cooling water applications.

- Q: What are the different sizes of plastic pipe fittings available?

- There are various sizes of plastic pipe fittings available, ranging from as small as ¼ inch to as large as 24 inches in diameter. The specific sizes of fittings depend on the type of plastic pipe being used and the application it is intended for.

- Q: Can plastic pipe fittings be used in water fountain systems?

- Yes, plastic pipe fittings can be used in water fountain systems. They are commonly used due to their durability, resistance to corrosion, and ease of installation. However, it is important to ensure that the plastic used is suitable for contact with water and meets any necessary regulations or standards.

- Q: Municipal water supply pipeline is a plastic pipe, then its matching valves and fittings are plastic?

- Municipal water supply pipe for water supply plastic pipe, the pipe supporting accessories, such as three pass joints, valves, etc., can be chosen according to specific circumstances.

Send your message to us

1 1/2 Inch PE Injection Elbow Welded Elbow Plastic Pipe Fittings for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords