1/2 Inch Plastic Water Pipe Fittings - 2024 PPR Elbow Fittings for Industrial Application from China Professional

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Advantanges

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat insulation and Saving Energy: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and good hot-melt performance can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly.

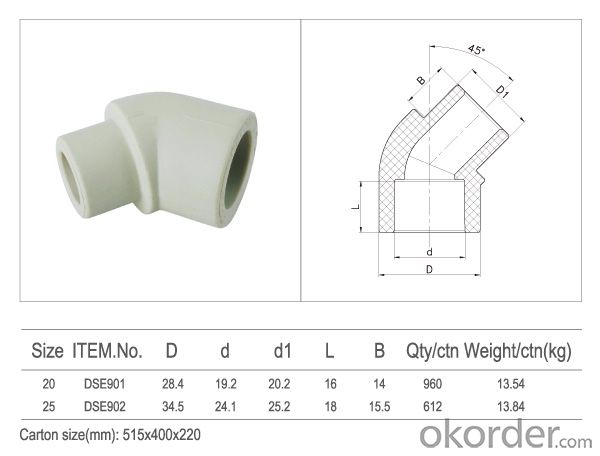

Product Description

Product Show

Why choose us?

(1) Professional factory: We are manufacturer, specializing in manufacturing multilayer PP-R, PE pipe and PP-R, PE pipe fittings for more than13 years, our price is competitive with high quality. And we can delivery product in quick way.

(2) Sample: We can send samples out in 3 days, but the express charge usually paid by your side, but the fee will be rebound when we have formal order.

(3) Rapid response to your needs: We will be answer within 24 hours. Welcome to contact with us if you have any problems. We are looking to cooperating with you.

(4) We hope we can establish long-term and mutual benefit business relation with you. If you have any problem, please kindly feel free to contact me. I will try the best to help you!

- Q: How do plastic pipe fittings compare to cast iron fittings?

- Plastic pipe fittings are generally more cost-effective, lightweight, and easier to install compared to cast iron fittings. They are also resistant to corrosion and chemical reactions, making them a popular choice for various plumbing and industrial applications. However, cast iron fittings are known for their durability, strength, and ability to withstand high pressure and temperature, making them suitable for heavy-duty applications. Ultimately, the choice between plastic and cast iron fittings depends on the specific needs and requirements of the project.

- Q: What are the common failure modes of plastic pipe fittings?

- Some common failure modes of plastic pipe fittings include leaks, cracks, and joint failures. These can occur due to factors such as excessive pressure, thermal expansion/contraction, chemical degradation, improper installation, or poor quality materials.

- Q: Are plastic pipe fittings suitable for mining operations?

- Yes, plastic pipe fittings can be suitable for mining operations. Plastic pipe fittings offer several advantages such as corrosion resistance, lightweight construction, and ease of installation. Additionally, plastic pipe fittings can withstand high pressures and are durable, making them suitable for various mining applications. However, the specific requirements and conditions of each mining operation should be considered to ensure proper selection and installation of plastic pipe fittings.

- Q: What are the common shapes and configurations of plastic pipe fittings?

- Common shapes and configurations of plastic pipe fittings include elbows, tees, couplings, adapters, unions, reducers, caps, and plugs. These fittings are available in various sizes and are designed to connect and redirect pipes in plumbing and industrial systems.

- Q: Can plastic pipe fittings be used in water treatment systems?

- Yes, plastic pipe fittings can be used in water treatment systems. Plastic pipe fittings are commonly used in water treatment systems due to their durability, resistance to corrosion, and ease of installation. They are often made from materials such as PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride) which can handle the demands of water treatment processes and provide long-lasting performance.

- Q: Do plastic pipe fittings require glue or solvent during installation?

- Yes, plastic pipe fittings typically require the use of glue or solvent during installation to ensure a secure and watertight connection.

- Q: Can plastic pipe fittings be recycled?

- Yes, plastic pipe fittings can generally be recycled. However, the ability to recycle them may vary depending on the type of plastic used and the recycling facilities available in your area. It is important to check with your local recycling program or facility to ensure they accept plastic pipe fittings for recycling.

- Q: Can plastic pipe fittings be used for geothermal heating and cooling systems?

- Yes, plastic pipe fittings can be used for geothermal heating and cooling systems. Plastic pipe materials such as high-density polyethylene (HDPE) or cross-linked polyethylene (PEX) are commonly used in geothermal systems due to their durability, flexibility, and resistance to corrosion. Additionally, plastic fittings are easy to install and can withstand the high temperatures and pressures associated with geothermal applications.

- Q: Can plastic pipe fittings be used in solar water heating systems?

- Yes, plastic pipe fittings can be used in solar water heating systems. Plastic fittings are commonly used in these systems due to their affordability, corrosion resistance, and ease of installation. Additionally, plastic fittings are compatible with the materials typically used in solar water heating systems, such as copper or PEX pipes. However, it is important to ensure that the plastic fittings chosen are specifically designed for hot water applications to ensure optimal performance and longevity in the solar water heating system.

- Q: How do plastic pipe fittings compare to metal fittings?

- Plastic pipe fittings are generally less expensive, more lightweight, and easier to install compared to metal fittings. However, metal fittings are typically more durable, have higher heat resistance, and offer better pressure handling capabilities. The choice between plastic and metal fittings depends on the specific application, budget, and desired performance.

Send your message to us

1/2 Inch Plastic Water Pipe Fittings - 2024 PPR Elbow Fittings for Industrial Application from China Professional

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords