PC Cap Making Machine Application for LED Light

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PC Cap Making Machine Application for LED Light

LED Light PC Cap Making Machine Production Line Feature:

Reasonable equipment design, compact construction, simple operation

Equipment with high degree automatic, cost less expenses

Electrical equipment, Hydraulic system, Seal parts and Lubrication system adopt the components of famous factory in the world, with low failure rate.

To achieve the best quality guarantee, no matter the appearance and internal, automatic PC Cap Making Machine rate of quality goods is above 99%.

LED Light PC Cap Making Machine Technical Characteristic:

LED Light PC Cap Making Machine adopt European technology, control the hydraulic system with pressure and flow double proportion. The speed of pressure can adjust nonpolarly, high stability, exchange control the electrical system with man-machine interface. Operating surface has a machinery safety configuration, two electrical safety configuration to ensure the safety of operators.

PLC+touch screen, making the operation easy. Automatic malfunction alarm with selfdiagnosis, making the malfunction clear at a glance.

Center input die head, eliminating the knit line completely and making it easy to change the material and color.

Double linear rolling motion guider in moving, opening and closing mold, making the clamping force equally distributed, so the cut is smoother.

Control the hydraulic system with imported proportional valve, ensuring the action steady, accurate and energy saving.

High speed and efficient plasticizing system, mixing well and ensuring the produce purity.

LED Light PC Cap Making Machine Parameter:

Specifications | Unit | Parameters |

Max container capacity | L | 20 |

Extruder System |

|

|

Screw Diameter | mm | 82 |

Screw L/D ratio | L/D | 30:1 |

Screw Speed | rev. / min. | 10~50 |

Plasticizing Capacity | Seconds/die. | 60 |

Number of heating zone barrel | zone | 5 |

Extruder driving Power of barrel | KW | 34 |

Max Injection quantity | L | 1.5 |

Die Head |

|

|

Max die diameter | mm | 130 |

Number of heating zone | zone | 4 |

Extruder driving power | KW | 8.7 |

Clamping Device |

|

|

Platen Size(WxH) | mm | 440 x 600 |

Platen opening stroke | mm | 330~780 |

Clamping force | KN | 210 |

Next blowing Device |

|

|

Blowing the head off and landing trip | mm | 120 |

Manual control Blowing the head off and landing trip | mm | 80 |

Manipulator |

|

|

Take pieces of travel | mm | 1000 |

Framework |

|

|

Lift travel | mm | 250 |

Hydraulic System |

|

|

Rated pressure of big pump | Mpa | 14 |

Rated flow of big pump | L/min | 180 |

Motor power of Hydraulic pumps | KW | 45 |

Parison Controlling Of Hydraulic Servo System |

|

|

Rated pressure | Mpa | 6 |

Rated Flow | L/min | 22 |

Motor power of Hydraulic pumps | KW | 4 |

Pneumatical System |

|

|

Air source pressure | Mpa | 1 |

Working pressure | Mpa | 0.8 |

Air consumption | M3 / min. | 0.6 |

Electrical Control System |

|

|

Water Supply |

|

|

Water supply pressure | Mpa | 0.3 |

Power Supply | ||

Voltage | V | AC380V±10% |

Frequency | HZ | 50 |

Wire |

| 3Phase |

Total of rated power | KW | 91.7 |

Average power consumption | KW.h | 45 |

Total weight | Ton | 11 |

Dimension of machine (Lx W x H) | m | 5.3×2.7×4.5 |

LED Light PC Cap Making Machine Parts Picture:

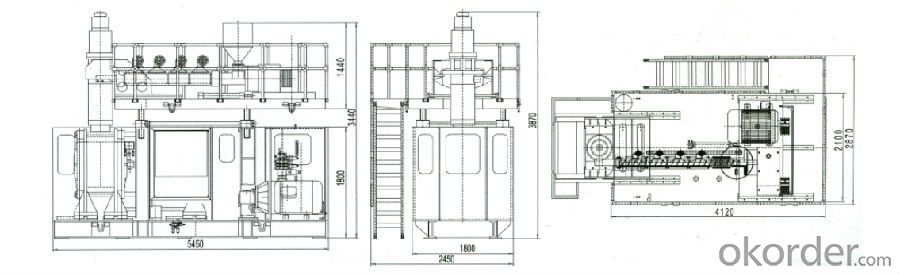

LED Light PC Cap Making Machine Drawing Picture:

LED Light PC Cap Making Machine Electrical Parts Photo:

LED Light PC Cap Making Machine Products Photo:

- Q: Excuse me, what's the reason why the oil is not clear and cloudy after being filtered by the centrifugal oil filter?

- The centrifugal oil filter can be used in addition to impurities, but the water removal effect is somewhat worse than that of the vacuum oil filter. The turbidity may be emulsified by the oil inlet

- Q: Transformer oil filter how to choose?

- Don't know how much of the transformer, how much oil, transformer oil, vacuum oil filter only high vacuum oil filter and double stage vacuum oil filter, if the oil is not much, is not particularly high efficient vacuum oil filter can, if need to improve the vacuum pressure value, and these. High altitude double stage vacuum oil filter machine, see you under questioning, if interested can go to look at the following address

- Q: What are the 3 basic requirements of hydraulic system for hydraulic oil filters?

- We have used hydraulic oil filters, three basic requirements, one is to select the flow rate suitable for hydraulic oil filter

- Q: What is the selection of the oil filter for the turbine?

- In addition, you are centralized filtration (that is, putting all the steam turbine waste in one place to filter), or on-line filtering will also affect the selection of the flow rate of the oil filter. For example, you centralized filtration, large amount of oil, if you request a day after the filtering, it must be 100 liters per minute or more, if you want to waste online filtration cycle, then certainly not centralized so high, so we can choose small flow. Also, look at your filter time requirements,

- Q: What is the advantage of a centrifugal oil filter?

- The centrifugal oil filter is to generate centrifugal force through the high-speed propaganda of the motor, and the oil sludge in the oil is thrown to the inner wall of the oil filter.For mature oil, the oil filter works better and faster.For low temperature, cold oil, the effect is not good.I hope my answer can help you.

- Q: What's the difference between a purifier and an oil purifier? Or the purifier is the oil filter

- The oil purifier basically eliminates impurities, and the purifier can also remove water except for impurities, but the average person thinks it is the same

- Q: Can vacuum turbine oil filters be used to filter transformer oils?

- Pure filtering is certainly no problem, after all, regardless of the filtration of turbine oil (turbine oil) or oil filter of transformer oil machine is vacuum oil filter, generally is the need to filter water, in the strict requirements under the condition that the theory can be filtered.

- Q: Imported vacuum purifier, oil filter, why Parker is known as the world's first?

- From the energy consumption, from the service, from customer satisfaction, a relatively clear, and also used to say?!

- Q: Who knows what the vibration of the oil filter is?

- You are welcome. We will do our best to help you with the oil filter. We will be the manufacturer of the oil filter

- Q: I opened a small youfang! The oil used in centrifugal oil filters is always mixed

- First of all: you open a small oil mill, then the general is the filtration of edible oil, edible oil filter using centrifugal oil filter is possible, but must be stainless steel, but also need to use 304 stainless steel.Second: the centrifugal oil filter mainly used high speed centrifuge to produce centrifugal force, and comprehensive settlement, such as the centrifugal filtration of water and impurities, according to your description after filtration or turbidity, the oil filter did not play a role, reasons are analyzed as follows:

Send your message to us

PC Cap Making Machine Application for LED Light

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords