High Adhesive Packaging Tape - Pack Tape Aluminum Foil Tape Industry Tape 3M Packing Tape

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of BOPP Tape Description

Widely used for cartom sealing and packing,light duty packing, bounding, holding and other office and household use.

2. Main Features of the BOPP Tape

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

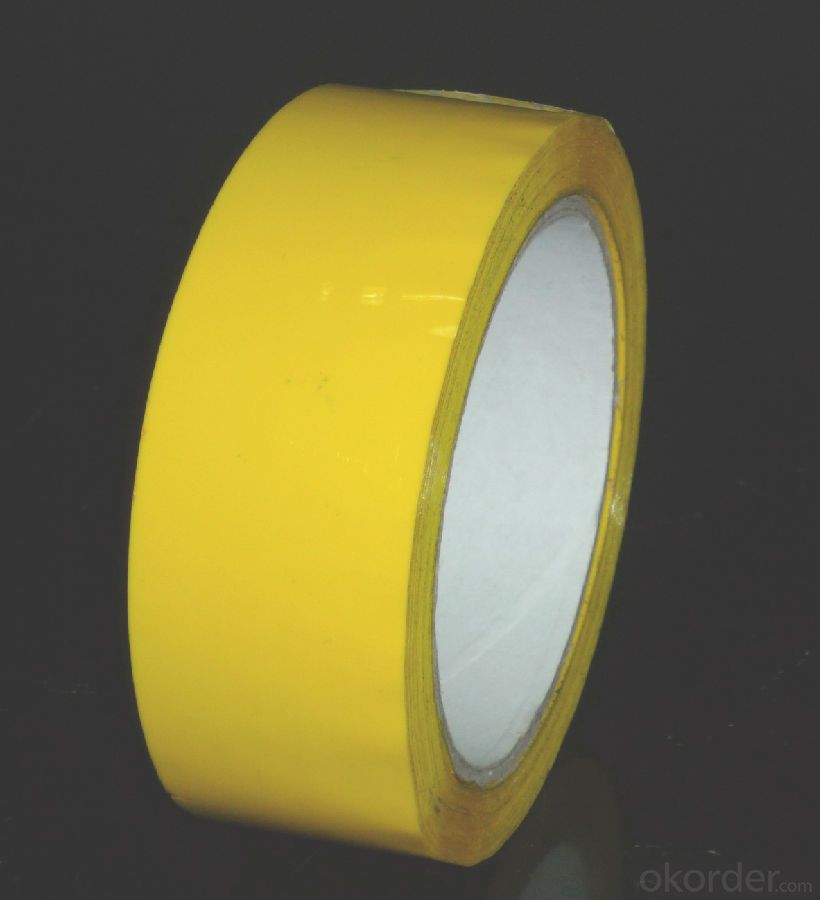

3. BOPP Tape Images

4. TYPICAL PHYSICAL PROPERTIES:

CONSTRUCTION:

Carrier: BOPP film

Adhesive: Water based acrylic adhesive.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 42 ± 1 um

Adhesive thickness:20 ± 1 um

Initial Tack: ³ 23#

180O Peel Adhesion (to steel): ³ 6.52 N /25mm

Holding Power: ³ 31 hrs

Item No. | Carrier | Adhesive | Total | Initial | Peel Adhesion | Elongation |

BP-40 | BOPP film | water based acrylic | 40 micron | >18# | 0.5kgf/25mm | <180%< span=""> |

BP-45 | BOPP film | water based acrylic | 45 micron | >18# | 0.5kgf/25mm | <180%< span=""> |

BP-50 | BOPP film | water based acrylic | 50 micron | >20# | 0.5kgf/25mm | <180%< span=""> |

BP-65 | BOPP film | water based acrylic | 65 micron | >24# | 7.88N/25mm | <180%< span=""> |

5.Advantage To Recommend:

We supply a wide range of products, which include double sided adhesive tape, masking tape, kraft tape, cloth tape, BOPP tape and so on.

Our biggest item is double side tape. Our double-sided adhesive tapes are with the carriers of tissue, PET, OPP, cloth, PE foam and EVA foam. And the adhesives involved are water based, solvent based and hot-melt acrylic adhesive.

According to different temperature resistances, we have two categories of masking tapes separately for general purpose and high temperature from 100°C to 160°C.

We also produce kraft tape, cloth tape and BOPP tape.

We have as our principle “Clients’ need comes first”. So we have a good variety of technical properties and sizes to meet with your different needs.

Our products enjoy popularity in markets because they have super quality with competitive price and good service.

Adhero is your ideal choice for excellent adhesive tapes and solutions.

6. FAQ:

1)What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2)What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3)How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4)Can Adhero accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5)What are the international commodity codes for these products?

HS Code: 48231900.

6)Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

7)What are the temperatures resistances of your masking tape?

we have two general kinds of masking tapes separately for general purpose 60°C and high temperature 100°C to 160°C.

8)Are you a manufacturer or just a trader?

We are a professional manufacturer.

9)How about the quality?

The quality is very good. We have large and advanced product line.welcome to visit our company.

- Q: Can packaging tape be used for sealing packages with breakable items like ceramics?

- Yes, packaging tape can be used for sealing packages with breakable items like ceramics. However, it is recommended to use additional protective measures such as bubble wrap or foam padding to ensure the safe transportation of fragile items.

- Q: Can packaging tape be used for sealing plastic tubing?

- Yes, packaging tape can be used for sealing plastic tubing. However, it may not be the most effective or durable option. It is generally recommended to use specialized tape or fittings designed specifically for sealing plastic tubing to ensure a secure and reliable seal.

- Q: How do I prevent packaging tape from tearing during removal?

- To avoid tearing when removing packaging tape, consider the following strategies: 1. Applying heat proves effective. Utilize a hairdryer or heat gun to warm the tape. The adhesive softens, facilitating tear-free removal. Exercise caution to prevent overheating or scorching. 2. A cutting tool, such as a utility knife or scissors, can be employed when tape removal becomes challenging. Carefully cut through the tape to prevent tearing, opting for smaller, manageable sections. 3. Adopt a patient and deliberate approach. Remove the tape gradually and at a low angle, exerting gentle pressure to avoid tearing. If met with resistance, pause and attempt different angles or apply heat to loosen the adhesive. 4. If the tape proves stubborn, seek assistance from a solvent like rubbing alcohol or adhesive remover. Apply a small amount to a cloth or cotton ball and gently rub the tape to dissolve the adhesive. Test the solvent on a discreet area first to ensure it doesn't damage the surface. 5. Make an informed tape selection. Opt for high-quality packaging tape with strong adhesion and good tensile strength. Reinforced or heavy-duty tapes are less prone to tearing. By employing these techniques cautiously, you can successfully remove packaging tape without tearing it.

- Q: What are the best practices for storing packaging tape rolls?

- To store packaging tape rolls effectively, it is recommended to: 1. Maintain a cool and dry environment: Ensure that the tape rolls are stored away from direct sunlight and humidity, as extreme temperatures can decrease the tape's effectiveness and adhesive properties. 2. Store the rolls in an upright position: This will help preserve their shape and prevent any damage or deformation. Additionally, it facilitates easy access and usage of the tape. 3. Utilize a tape dispenser: Investing in a tape dispenser is a beneficial method for storing packaging tape rolls. Not only does it keep the rolls organized, but it also shields them from dust, dirt, and accidental harm. 4. Properly seal the rolls: After using the tape, make sure to securely seal the rolls. This prevents the accumulation of dust and debris on the adhesive side, preserving the tape's effectiveness for future application. 5. Maintain an inventory of tape rolls: It is advantageous to keep a record of the number of tape rolls in stock and their respective sizes. This aids in planning and restocking, avoiding any inconveniences or delays during the packaging process. 6. Avoid proximity to chemicals and sharp objects: It is essential to keep packaging tape rolls away from chemicals, solvents, or sharp objects that could potentially harm the tape or compromise its adhesive properties. By adhering to these best practices, you can guarantee that your packaging tape rolls remain in optimal condition and are readily accessible whenever required.

- Q: How do I remove packaging tape residue?

- To remove packaging tape residue, you can start by applying a small amount of oil or rubbing alcohol to a cloth or sponge and gently rubbing the affected area. This should help loosen the adhesive. Alternatively, you can also try using a mixture of warm water and dish soap, or a commercial adhesive remover. Make sure to test any method on a small, inconspicuous area first to ensure it doesn't damage the surface.

- Q: How do I prevent packaging tape from becoming too sticky?

- To prevent packaging tape from becoming too sticky, there are a few measures you can take: 1. Store tape in a cool and dry place: Heat and humidity can often cause the adhesive on packaging tape to become stickier. Ensure that you store the tape in a cool and dry environment to maintain its proper consistency. 2. Avoid contact with dust and debris: Dust and debris can stick to the adhesive side of the tape, increasing its stickiness. Keep the tape away from dusty surfaces and make sure the areas where you will apply the tape are clean and free from any loose particles. 3. Use a tape dispenser: A tape dispenser can help regulate the amount of tape you apply and prevent excessive stickiness. It allows for a more controlled application and ensures you don't use more tape than necessary. 4. Don't stretch the tape excessively: Stretching the tape too much while applying it can cause it to become stickier. Apply the tape smoothly without pulling or stretching it excessively, as this can activate the adhesive further. 5. Consider using low-tack or removable tape: If you consistently face issues with sticky packaging tape, you can opt for low-tack or removable tape. These types of tape have less aggressive adhesive properties and are easier to remove without leaving sticky residue. By following these tips, you can maintain the desired level of stickiness on your packaging tape and make your packaging process more efficient.

- Q: How do I prevent packaging tape from losing its adhesive properties?

- To prevent packaging tape from losing its adhesive properties, it is important to store it in a cool, dry place away from direct sunlight and extreme temperatures. Additionally, ensure that the surface where the tape is applied is clean and free from any dust, oil, or moisture, as these can compromise the adhesive. Applying the tape firmly and evenly, avoiding excessive stretching, can also help maintain its adhesive strength.

- Q: Can packaging tape be used for sealing pet food or treats?

- Yes, packaging tape can be used for sealing pet food or treats. It provides a strong and secure seal to keep the contents fresh and protected. However, it is important to ensure that the tape used is safe for pets, meaning it should be non-toxic and not contain any harmful substances that could potentially be ingested by the animals. It is recommended to use pet-safe packaging tape specifically designed for sealing pet food or treats, as it meets the necessary safety requirements and regulations.

- Q: What is the profit margin of the transparent tape for packaging?

- Come in 7, 2, generally sell 10, the key is to take the amount

- Q: What are the common brands of packaging tape?

- Some common brands of packaging tape include Scotch, Duck, 3M, Gorilla, and Uline. These brands are well-known for their durability, adhesive strength, and ease of use. They offer a variety of options including clear, tan, and colored tapes, as well as different widths and lengths to suit various packaging needs. Additionally, these brands often provide options for different types of packaging materials such as cardboard boxes, plastic bags, and bubble wrap. It's important to choose a reputable brand when selecting packaging tape to ensure secure and reliable sealing of packages.

Send your message to us

High Adhesive Packaging Tape - Pack Tape Aluminum Foil Tape Industry Tape 3M Packing Tape

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords