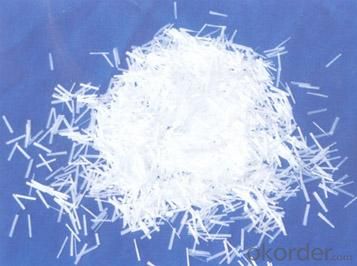

Owens Corning Chopped Strand Fiberglass for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Chopped Strands for BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry.

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High impact strength; High LOI rate

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Is fiberglass chopped strand suitable for automotive applications?

- Yes, fiberglass chopped strand is suitable for automotive applications. It is commonly used in automotive parts such as body panels, hoods, and interior components due to its high strength, lightweight, and corrosion-resistant properties. Additionally, it provides excellent impact resistance and can be easily molded into complex shapes, making it an ideal material for automotive applications.

- Q: What are the typical fiber lengths used in fiberglass chopped strand?

- The typical fiber lengths used in fiberglass chopped strand can vary depending on the specific application and requirements. However, most commonly, the fiber lengths range from 3-6 mm (1/8-1/4 inch). These shorter fiber lengths are preferred as they provide better dispersion and distribution within the resin matrix, resulting in improved overall strength and performance of the fiberglass composite. Additionally, shorter fiber lengths also help to minimize the potential for fiber entanglement and clumping during processing. However, it is important to note that longer fiber lengths can also be used in certain specialized applications where increased strength or specific properties are desired. Ultimately, the choice of fiber length in fiberglass chopped strand is determined by the specific needs and characteristics of the intended end use.

- Q: What are the different forms of fiberglass chopped strand available?

- There are several different forms of fiberglass chopped strand available, including continuous strand mat, chopped strand mat, woven roving, and chopped strand.

- Q: What are the quality control measures for fiberglass chopped strand storage and handling?

- Quality control measures for fiberglass chopped strand storage and handling typically include the following steps: 1. Proper storage conditions: Fiberglass chopped strand should be stored in a clean, dry, and temperature-controlled environment to prevent moisture absorption and maintain its integrity. 2. Handling procedures: Personnel involved in the storage and handling of fiberglass chopped strand should be trained to handle the material with care, avoiding excessive bending, crushing, or dropping that may cause damage. 3. Packaging integrity: The packaging of fiberglass chopped strand should be inspected to ensure it is intact and free from any punctures or tears that could lead to contamination or moisture absorption. 4. Regular inspections: Regular visual inspections should be conducted to check for any signs of damage, such as broken strands, discoloration, or foreign particles, which may affect the quality of the material. 5. Documentation and traceability: Proper documentation and labeling should be maintained to track the storage and handling of fiberglass chopped strand, allowing for traceability and accountability in case of any quality issues. Overall, these quality control measures aim to ensure the proper storage and handling of fiberglass chopped strand, minimizing the risk of contamination, damage, or degradation, and ultimately maintaining the desired quality of the material.

- Q: Can fiberglass chopped strand be used in medical applications?

- Fiberglass chopped strand can be used in certain medical applications, but it may not be suitable for all medical devices or procedures. The use of fiberglass chopped strand in medical applications depends on several factors, including the specific requirements of the application and the regulations governing medical devices. Fiberglass chopped strand is commonly used in the production of composite materials and is known for its strength, durability, and heat resistance. These properties make it suitable for a wide range of industrial applications, including automotive, aerospace, and construction industries. However, when it comes to medical applications, additional considerations must be taken into account. One important aspect to consider is the potential for biocompatibility. Medical devices that come into direct contact with the human body need to be biocompatible, meaning they should not cause any adverse reactions or harm to the patient. Fiberglass chopped strand is not inherently biocompatible, but it can be coated or treated to make it suitable for medical use. Coatings or treatments can help minimize the risk of any adverse reactions or interactions with the patient's body. Additionally, regulatory requirements play a crucial role in determining the usability of fiberglass chopped strand in medical applications. Medical devices are subject to strict regulations and standards to ensure their safety and efficacy. The use of fiberglass chopped strand in medical devices may need to comply with specific regulations, such as the U.S. Food and Drug Administration (FDA) regulations in the United States or the European Medical Device Regulation (MDR) in the European Union. These regulations often require extensive testing and documentation to demonstrate the safety and effectiveness of the materials used in medical devices. In conclusion, while fiberglass chopped strand can be used in certain medical applications, its suitability depends on various factors, including biocompatibility and compliance with regulatory requirements. It is important for manufacturers and designers of medical devices to carefully assess these factors and consult with experts in the field to determine the appropriateness of fiberglass chopped strand for their specific application.

- Q: What is the thermal shock resistance of fiberglass chopped strand?

- The thermal shock resistance of fiberglass chopped strand is generally high, as it can withstand rapid changes in temperature without cracking or breaking.

- Q: How is the adhesion strength of fiberglass chopped strand composites tested?

- Various methods are typically utilized to test the adhesion strength of fiberglass chopped strand composites. One commonly employed approach is the single fiber pull-out test. This method entails embedding individual fibers within a matrix material and subsequently extracting them to measure the force necessary for fiber detachment from the matrix. By conducting this test, the interfacial bond strength between the fibers and the matrix can be assessed. Another method employed is the short-beam shear test. In this test, a composite sample with a specific geometry is subjected to a three-point bending load. The maximum load at the point of failure is measured, thereby providing valuable information regarding the adhesion strength between the fibers and the matrix. Moreover, the peel test can be implemented to evaluate the adhesion strength. This test involves separating a composite laminate into layers and quantifying the force required to peel the layers apart. Through this test, valuable insights into the interfacial bond strength between the layers can be obtained. Furthermore, the pull-off test can be utilized to determine the adhesion strength between the composite and a substrate. This test involves applying a force perpendicular to the surface of the composite and measuring the maximum force needed for delamination from the substrate. Ultimately, these testing methods enable the evaluation of the adhesion strength of fiberglass chopped strand composites by quantifying the force needed for fiber detachment, the maximum load at failure, peel strength, or pull-off force. These tests play a vital role in assessing the quality and performance of composite materials, thereby ensuring their suitability for diverse applications.

- Q: Is fiberglass chopped strand compatible with other reinforcement materials?

- Indeed, fiberglass chopped strand harmonizes well with other reinforcement materials. By amalgamating it with carbon fiber, Kevlar, or natural fibers, one can fabricate hybrid composites boasting superior mechanical characteristics. The amalgamation of diverse reinforcement materials can result in heightened durability, rigidity, and resistance to impacts within the ultimate composite product. Furthermore, fiberglass chopped strand can be utilized alongside thermoplastic or thermosetting resins, generating composite materials suitable for a wide range of applications in industries like automotive, aerospace, construction, and marine.

- Q: How does the fiber pull-out resistance of fiberglass chopped strand affect the performance of composites?

- The fiber pull-out resistance of fiberglass chopped strand significantly affects the performance of composites. A higher fiber pull-out resistance ensures better mechanical properties, such as increased strength and stiffness, improved fatigue resistance, and enhanced load-bearing capabilities. This resistance prevents the fibers from slipping out of the matrix material, allowing them to effectively transfer stress and contribute to the overall structural integrity of the composite. Therefore, a higher fiber pull-out resistance positively impacts the durability and performance of composites in various applications.

- Q: How does the density of the chopped strand affect its performance?

- The density of the chopped strand can greatly impact its performance. A higher density usually results in better mechanical properties such as strength and stiffness. It also enhances the strand's ability to resist impact and fatigue. On the other hand, a lower density may offer improved flexibility and better resin penetration. Ultimately, the suitable density depends on the specific application and desired performance characteristics.

Send your message to us

Owens Corning Chopped Strand Fiberglass for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords